公司 PROFILE COMPANY介绍

中科坤悦(北京)科技有限公司,是一家集工程服务、运营管理服务、装备制造、科技研发孵化及产业化推广为一体的多元化企业。公司与中国科学院山西煤炭化学研究所、中国矿业大学等国内外科研院所及高校深度合作,坚持“固废完全资源化利用”为导向,专注减污降碳技术。

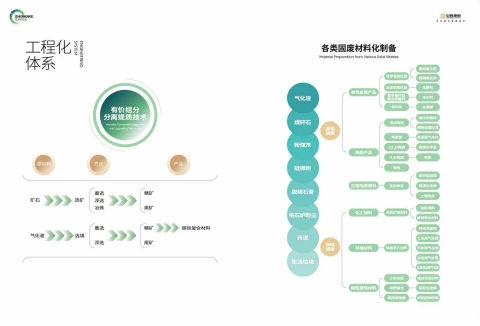

在“双碳”战略目标下,公司致力于矿物资源及大宗固废资源开发利用、二氧化碳减排等技术的研发与推广,提供粗细粒有价矿物分选技术、大宗固废有价组分分离提质技术、二氧化碳捕集及矿化技术,并为尾矿提供一系列材料化制备技术。

公司业务涉及矿物分选,煤研石、气化灰渣、粉煤灰等大宗固废处理,工业废水处理,尾矿资源回收利用等方面,为能源工业化利用过程提供固废清洁高效处理及资源化利用的整体解决方案和全过程服务。

ZHONGKE KuNYUE(Bejing)Technology Co.Ltd.is a diversified enterprise integrating engineering services,operation management services,equipment manufacturing.technological R&D incubation and industrialization promotion.The company collaborates deeply with research institutions and universities both domestically and internationally,including Institute of Coal Chemistry Chinese Acodemy of Sciences and China University of Mining and Technology. Upholding "Complete Solid Waste Resource Utization' as itsguiding principle,the company is dedicated to polltion reduction and carbon reduction technologiesili:

UndertheDual Carbon'stotegic godsthecompanyi committed to the R&D and promotionof technologie for mineralresourcesandbulksoudwasteresourcedevelopmentandutilization,andcarbondioxideemissionreduction. It providesvaluable mineral sarting technologyfor coarse andfineparticles,valuable componentseparation and upgrading technology forbulk solid waste,carbon dioxide capture and mineralization technology.and a series of materialpreparation technologies fortailings.

fty ash,etc.industrilwastewater treatment, and tallingsresourcerecycling.among others.Itcan providecomprehensive solutions andfull-process servicesforclean and eficient treatment andresource utilizationof solid wastein theenergy industrialization process,

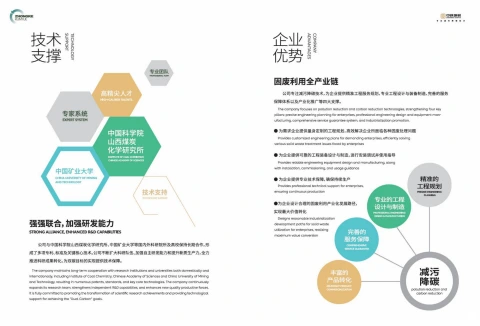

技撑 SUPPORT TECHNOLOGY

强强联合,加强研发能力 STRONGALLIANCE.ENHANCEDR&D CAPABILITIES

公司与中国科学院山西煤炭化学研究所、中国矿业大学等国内外科研院所及高校保持长期合作,形成了多项专利、标准及关键核心技术。公司不断扩大科研队伍、加强自主研发能力和提升新质生产力,全力推进科研成果转化,为双碳目标的实现提供技术保障。

The company maintains long-term cooperation with research institutions and universities both domestically and internationally,including Institute of Coal Chemistry, Chinese Acadermy of Sciences and China University of Mining and Technology.resuting innumerous patents,standards,and key core technologies.The companycontinuously expands its research team, strengthens independent R&D capabilities, and enhances new quality productive forces. It is fully committed to promoting the transformation of scientific research achievements and providing technological supportforachieving theDualCarbon'goals.

企业 ADVANTAGES COMPANY优势

固废利用全产业链

公司专注减污降碳技术,为企业提供精准工程服务规划、专业工程设计与装备制造、完善的服务保障体系以及产业化推广等四大支撑。

The company focuses on pollution reduction and carbon reduction technologies,strengthening four key pllars: precise engineering planning for enterprises, professional engineering design and equipment manufacturing.comprehensive service guaranteesystem,and industrialization promotion.

科研 TEAM RESEARCH团队

贫队 TEAMLEADER RESEARCH

李磊,研究员,博士生导师,任职于中国科学院山西煤炭化学研究所,煤炭高效低碳利用全国重点实验室主任助理,课题组长,入选中国科学院青促会会员、山西省“三晋英才”青年优秀人才计划。担任全国煤化工标准化技术委员会委员、中国能源学会碳中和专业委员会副秘书长以及山西省化学会第九届理事会理事等职务,主要从事CO2捕集及转化、减污降碳以及高端化学品合成方向研究,作为项目负责人承担了项目30余项,完成了多项技术中试与示范。在ACSCatalysis、Applied Catalysis B、TheInnovation、Chem.Eng.J.JCO2Uti等期刊发表论文70余篇,申请、授权专利30余项,主持和参与制定标准10余项,获得了国际XPRIZECarbonRemoval中国预热赛T0P10、中国发明协会发明创业奖成果奖一等奖以及中国循环经济协会科技进步二等奖等奖项。

中国科学院青促会会员“三晋英才”获得者

李磊 研究员/博导

ULei,

Researcher/Doctoral Supervisor, Member of theYouth Innovation Promotion Association of CAS Recipient of the“San Jin Talents" Program

U Le,esearcher,Doctoral Supervisor,DirectorAssistant of the State Key Laboratory Coal Efficient and Clean Conversion, Institute of Coal Chemistry, Chinese Acodemy of Sciences,and GroupLeader.Selected as a member of the Youth Innovation Promotion Associationi of the Chinese Academy of Sciences ond the "San Jin Talents" Youth Outstanding Talent Program in Shanxi Province. Serves as a member of the National Coal Chemical StandardizationTechnical Committee,DeputySecretary-General of the Carbon NeutralityProfessional Committee of the China Energy Society.and Director of the 9th Council of the Shanxi Chemical Society.His research focuses on CO capture and conversion, pollution reduction and carbon reduction, and the synthesis of highend chemicals. As project leader, he has undertaken over 30 projects and completed multiple technology pilot tests and demonstrations. Has published over 70 papers in journals such as ACs Catalysis, Applied Catalysis B, The Innovation, Chem.Eng.J, and J CO: Util, and applied for and authorized over 30 patentspresided over and particpated in the formulation of over 10 standards, and won awards including the International XPRZE CarbonRemoval China Pre-Competition TOP10,the First Prize of the Invention and Entrepreneurship Award of the China Association of Inventions, and the Second Prizeof the Science and Technology Progress Award of the China Association of Circular Economy.

张海军,国家杰出青年科学基金获得者、国家重点研发计划项目首席,现任中国矿业大学化工学院院长。主要从事矿物分离过程强化理论与装备、二次资源综合利用、工业固废资源化方面科研工作。主持或完成国家重点研发计划项目(课题)、国家科技支撑计划课题国家自然科学基金联合基金重点项目、国家优秀青年科学基金等国家和省部级以上科研项目12项,承担校企重大横向科研项目10余项;第一/通讯作者发表SCI/EI论文80余篇;授权国内外发明专利30余件;获国家科技进步二等奖1项、省部级科技进步二等奖4项、国家行业协会科技进步一等奖6项。

张海军 研究员/博导

国家杰出青年基金获得者中国矿业大学化工学院院长

ZHANG Haijun,

Researcher/DoctoralSupervisor, Recipient of the National Science Fund forDistinguished Young Scholars

Dean of the School of Chemical Engineering,China University of Mining and Technology

ZHANG Hojun, Recipient of the National Science Fund for Distinguished Young Scholars and Chief Scientist of a National Key R&.D Program,Dean of the School of Chemical Engineering and Technology at China University of Mining and Technology. Mainty engoged inresearch on the theory and equipment for strengthening mineral separation processes, comprehensive utilization of secondary resources, and industrial solid woste resource utilization. Has presided over or completed 12 projects including the National Key R&D Program (project) of China, the National Science and Technology Support Program Project, the Joint Fund Key Project of the National Natural Science Foundation of China, the Nationol. Excellent Young Scientists Fund Project, and the Nationol Key Rs.D Program Project,Undertakenmore than10 majorindustry-universitycolaborativeresearchprojects Has published over 80 SCl/El papers as the first or corresponding outhor, and authorized Over 30 domestic and intemotionol invention potents.Awarded 1 Second Prize for National Science and Technology Progress, 4 Second Prizes for Provincial and Ministerial Science and Technology Progress,and 6 First Prizes for Science and Technology Progress from national industry associations.

技术 TEAM TECHNICAL团队

中国科学院山西煤炭化学研究所李磊研究员课题组是国内较早从事CCUS方向研究的团队之一。课题组以CCUS技术研究主线,定位应用基础研究,通过实验室基础研究、小试验证、中试验证和示范合作的模式,打通从理论研究到产业过程的技术路径。在CO.捐集、催化转化方面进行了深入的基础和理论研究,先后完成了国内首台套循环流化移动床CO,吸附中试示范,开展了低碳烷经CO,重整制合成气CO氧化烷经脱氢、CO加氢合成醇类、CO:间接合成酯类化学品、CO矿化固废协同减污降碳等中小试技术验证,为进一步工业放大和系统集成化奠定了坚实的基础。同时团队在固废资源化利用、煤基/生物基高端化学品合成以及工业过程碳足迹潮源方向与企业开展了多项技术合作,取得了丰硕的科研成果。团队先后承担了国家级、国际合作、省部级及企业合作等项目50余项,在相关领域累计发表论文100余篇,申请,授权专利及制定相关标准30余项,近年来团队获得了山西省科技创新人才团队江苏省人才攻关联合体专项支持,并荣获多项科技奖励。

Theresearchgroup ledbyResercheriLeiof thenstituteofCodlChemistryCninesecodemyof ciencesShanxlisneof theearliest teas inChinoengogedinCcuSresearchTheresearchgroup tokesCcus technologyreseorchas itsmoin focus andpositlonsitself inappliation orlented basicresearchThrough laborotory basicresearchsmol-scoletestingplot-scole testing,nd demonstrotion cooperatlon,it estobl shes o technologioolpatrway from theoreticolresearchtoindustrial processes.In-depthbosic and theoreticalresearch hos beenconducled on COcopture andcotalyticconversionThe grouphas successivelyconpletedChina'sfirstsetofcirculating fluidized bed COadsorption pilotdemonstrationsand carriedout small-scalepilol technologyvalidabonfor low-carbonolkane COhreforming tbsyngas,cOoxidative dehydrogenotionof olkanes,cOahydrogenation toalcohols,COindirect synthesisof esterchemicolsandcominerolizotionof solid woste forcollaborotive pollution ond carbonreducton. loying a solid foundotion for further incustrial scale-up and system integrotion.Simuttaneo usly.the teamhos carriedoutmulipletechnologycooperationprojectswithenterprisesin thegreasof solidwasteresourceutilizationcool bosed/biobosed highrendchemical synthesis.andindustril process carbon footpnnt trocing.ochieving fruitfutreseorchresults.The teom has successivelyundertakenoveroprectst thenotionalintemotionalcooperationprovincdndministerollevelsandenterprisecoop erotion levels.nreloted felds,ithoscumulotively published over100popersppled forand uthorizedover 30 potentsond formuloted relevontstondords,Inrecentyearsthe teamhasreceved supportfrom theShanki ProvincialScienceandTechnologyInnovalionTalentTeam Cnd theJiongsu Provincal Key R&.D Progrum-Joint Innovalion Consortiumond hos won multiple science ond technology owords

企业 COMPANY荣誉

专利标准及 ANDAWARDS STANDARDS PATENTS荣获奖项

The company has obtained numerous domestic and international patents, led and participated in the formulation of multiple standards,and developed equipment and technologieswith independent intellectual property rights.It provides professional technical support and services to partner enterprisesand holdsa leadingposition in theindustry.

奇源理固废 WASTE TYPES TREATABLESOLID

废源化 UMIUZATION TECHNOLOGY SOUD WASTE RESOURCE

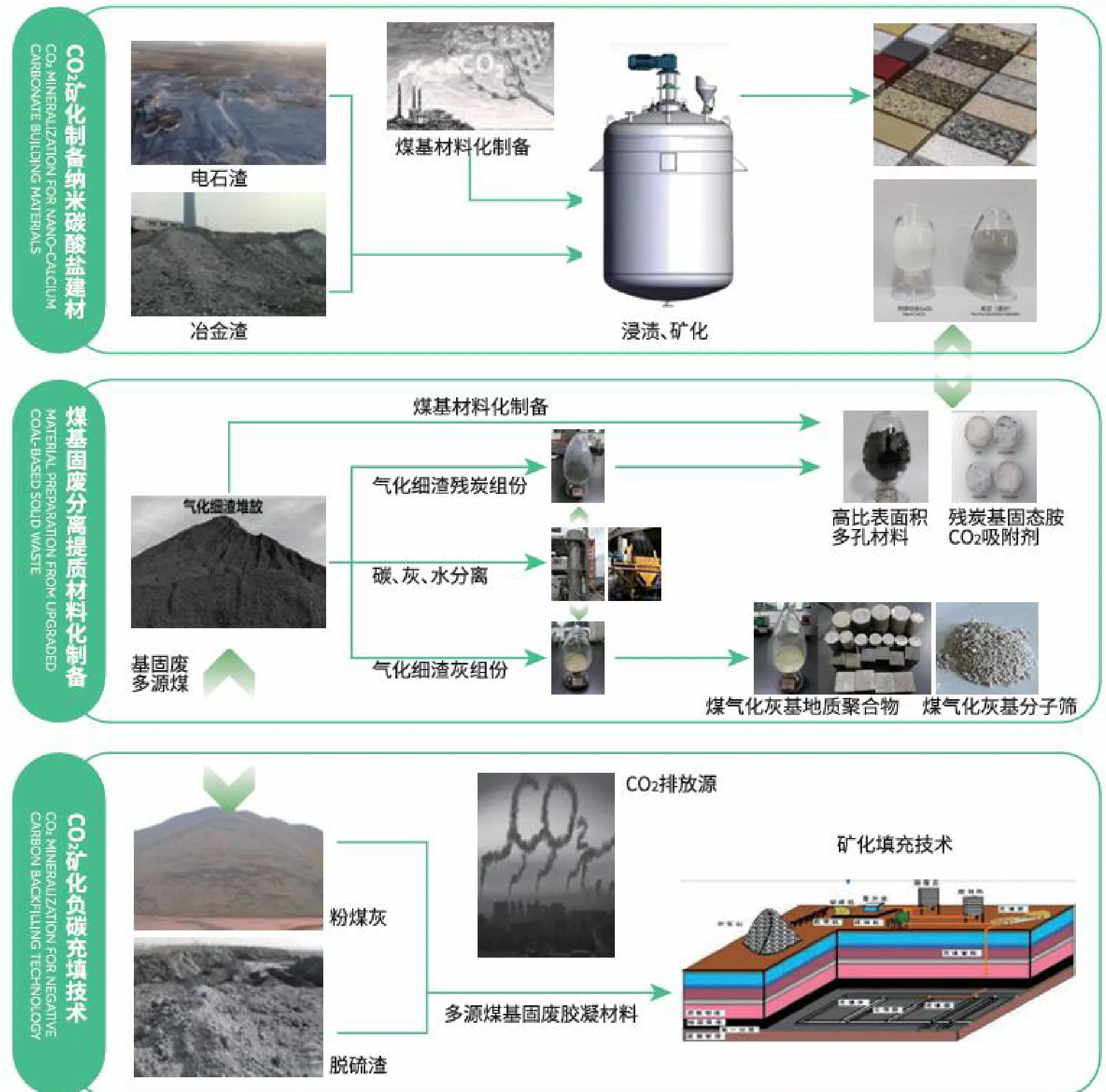

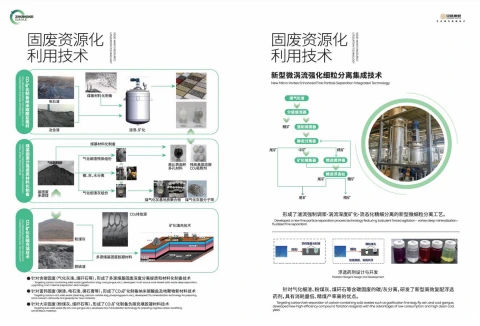

●针对含碳固废(气化灰渣、煤研石等),形成了多源煤基固废深度分离提质和材料化制备技术upgrading,ond materiol preparation technologies

●针对富钙固废(钢渣、电石渣、磷石膏等),形成了CO矿化制备纳米碳酸盐及地聚物新材料技术Targetinghlwtestescmabihgumtvelmerlitlgfinanocalcium carbonate and geopotymer new materiols

●针对大宗固废(粉煤灰、煤研石等),形成了CO2矿化制备负碳充填胶凝材料技术Tagetinguksldwtfyhlngueelclgfngetrcementitiousmaterials

废资源化 UTIUZATIONTECHNOLOGY SOUD WASTERESOURCE

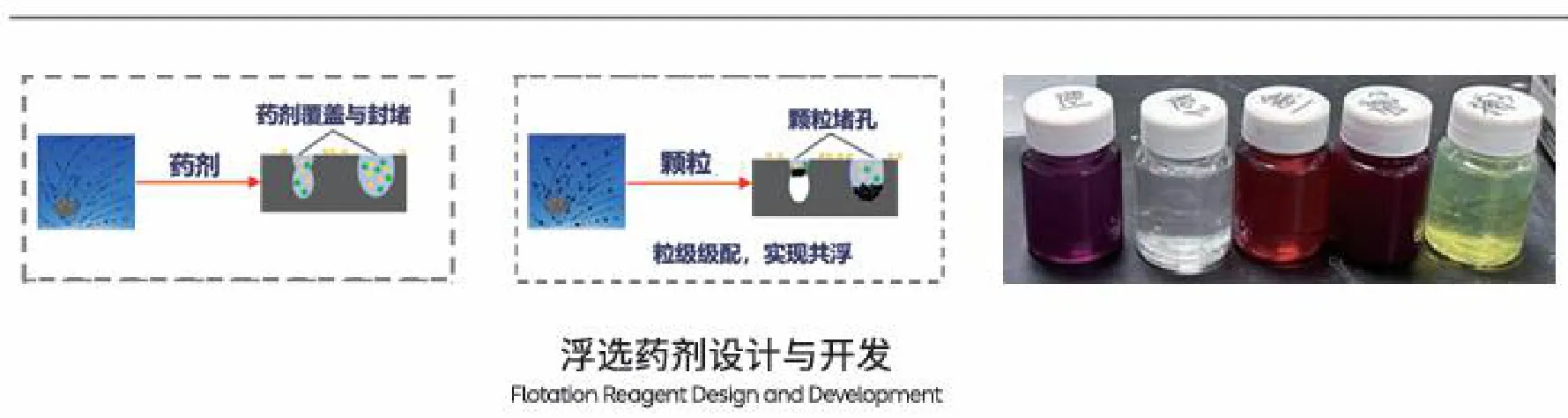

形成了湍流强制调浆-涡流深度矿化-流态化精细分离的新型微细粒分离工艺。 Developedanewfne particleseparationprocesstechnologyfeaturingturbulent forcedagitation-vortexdeepmineralization fluidized fineseparation.

针对气化细渣、粉煤灰、煤研石等含碳固废的碳/灰分离,研发了新型高效复配浮选药剂,具有消耗量低、精煤产率高的优点。

Targetingcarbon/ashseparationafcarbon-containing solidwastessuchas gasificationfineslagflyash,andcoalgangue developed new high-effciency compound flotationreagents with the advantages of lowconsumption and highclean coal yield.

虏资源化 UTILIZATION TECHNOLOGY SOLID WASTERESOURCE

废资源化 SUOLILAWIAST ESOULCGY

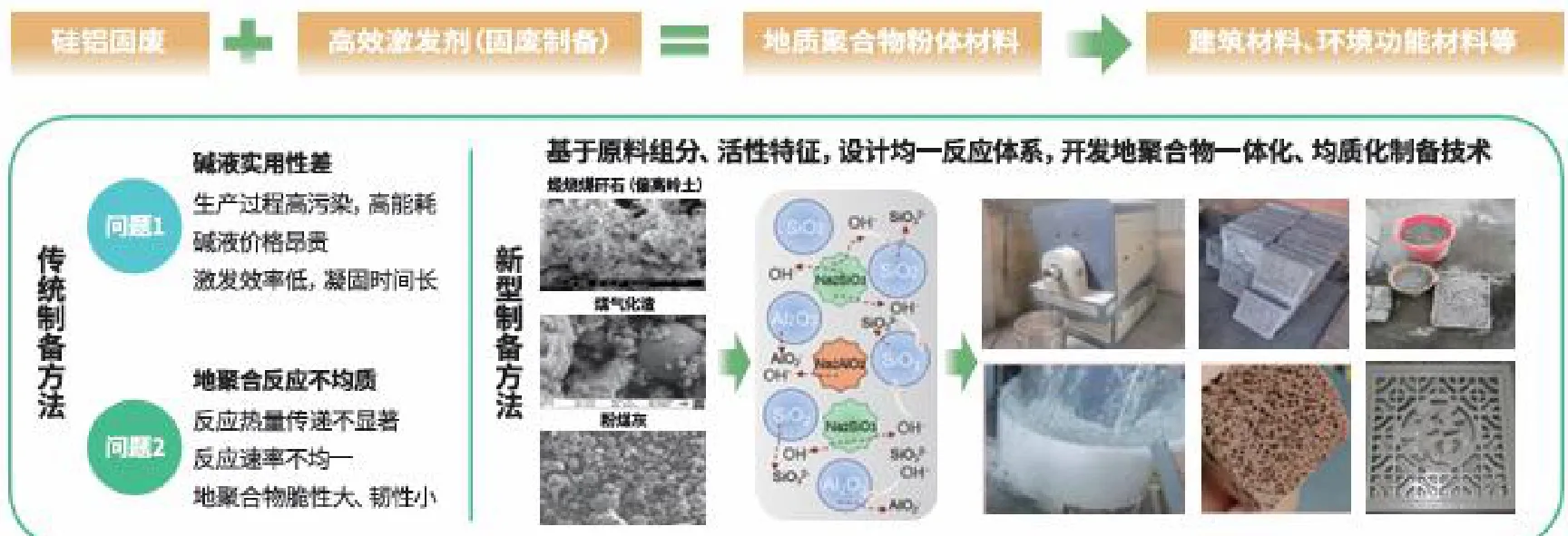

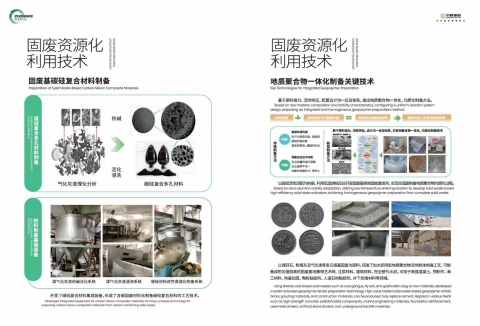

地质聚合物一体化制备关键技术 KeyTechnologiesforlntegrated GeopolymerPreparation

基于原料组分、活性特征,配置设计均一反应体系,提出地质聚合物一体化、均质化制备方法。 Based onrawmaterial composition and activity characteristics, configuring a uniformreaction system esian. oroposina an intearated and homoaeneous aeopolvmer orenaration method.

以硅铝活性适配为依据,利用低温烧结反应开发固废基高效固态激发剂,实现全固废制备地质聚合物均质化过程。 Based on silicc-alumina activityadaptation,utilizing low-temperature sintering reactiontoevelopsolidwaste-based nigh-efficiencysolid-state activators,achievinghomogeneousgeopolymerpreparationfromcomplete solidwaste.

Using diverse coal-based solid wastes suchascoal gangue,fly ash,and gasification slag as rawmaterials,developed awater-activated geopolymerbinder preparation technology.Highvalue-added solidwaste-basedgeopolymerartistic bricks.groutingmaterials,andconstructionmaterials,canbeproducedfullyreplacecementApplied invariousfelds such ashigh-strength concrete,prefabricated components,marine engineeringmaterials,foundationreinforcement ceramsitebinders,artificialstonebinders,and undergroundbackfillmaterials.

废源化 UMUZATIONTECHNOLOGY SOUD WASTE RESOURCE

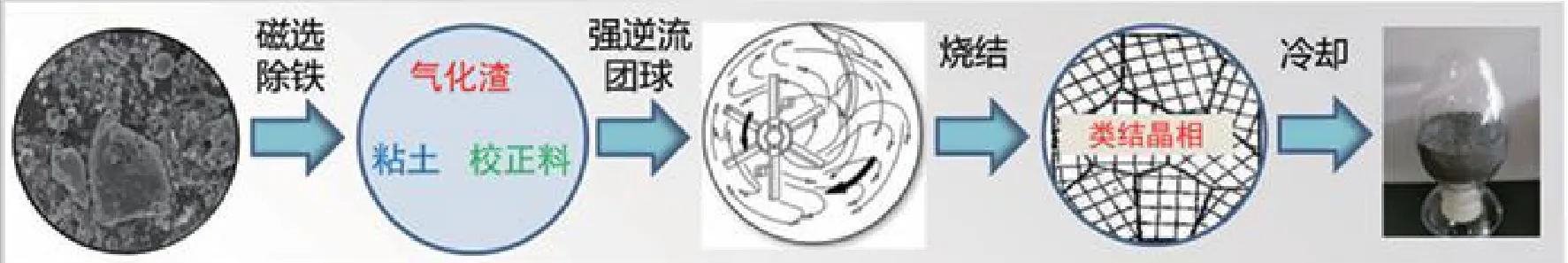

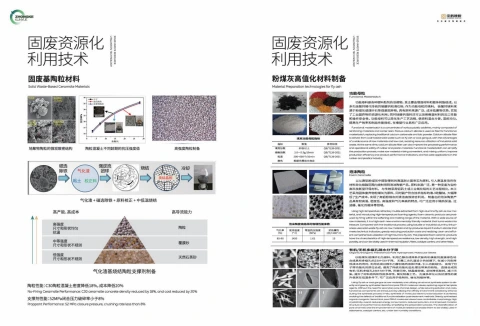

固废基陶粒材料

气化渣基烧结陶粒支撑剂制备

陶科性能:5U陶科混凝工密度降低18%,成本降低20%

No-Firing CeramsitePerformance:C30ceramsite concrete densityreduced by \mathbb{1}E_{N_{i}}^{E} andcostreducedby E D=9 支撑剂性能:52MPa闭合压力破碎率小于 9% Proppant Performance:52MPa closure pressure,crushing rate less than 8%

虏源化 UTIUZATIONTECHNOLOGY SOUD WASTE RESOURCE

功能母料是各种塑料助剂的浓缩物,其主要由增强材料和载体树脂组成。以多孔硅酸钙替代传统的碳酸钙和滑石粉,作为功能母粒的填料。硅酸钙填料来源于粉煤灰或煤研石等煤基固弃物,具有原料来源广泛,成本低廉等优劳,实现了工业固弃物的资源化利用;同时硅酸钙填料还可以改善橡塑材料的加工性能和操作安全性。功能母料可以简化生产工艺流程,使原料混合方便,混炼均匀,提高生产效率和制品性能指标,在橡塑行业具有广泛应用。

Functional masterbatch is a concentrate of various plostic additives, mainly cormposed of reinforcing moteriols ond carrer resin. Porous colcium sllcote Is used os filler for functionol. masterbatch, replacing trodibonal calcum carbonate and tolc powder, Calcum silicate filer is cerived from coal-based souid waste such as flty osh or cool gangue, with the advanitoges of a wide source of raw materidls and low cost, realizing resource utilizatlon of industrial solld waste At the same time, calcum silicate filler can also improve the processing perfommance and operotlonal sofety of rubber and plostic moteriols. Functional mosterbatch can simplify the production process, make rcw material mbdng corivenient, and midng uniform, improve production effciency and product perforrmance indlcators, and hos wde applications in the rubberand plastics Industry.

泡沫陶粒

以从高铝粉煤灰中提取得到的高温耐火莫来石为原料,引入高温发泡剂在材料软化熔融范围内烧制得到泡沫陶瓷产品,原料来源广泛,是一种变废为宝的高科技新型环保材料。与传统来用铝矾土或工业氧化铝的工艺过程相比,本工艺采用固体废弃物粉煤灰为原料,同时副产符合技术指标的液-3硅酸钠,大幅降低了生产成本,实现了高铝粉煤灰的清洁高效综合利用。制备出的泡沫陶瓷产品具有耐高温、密度低、高强度和气孔率高的特点,可广泛应用于阴热保温、过滤器、催化剂载体等领域。

Using high-temperature refractory muuite extracted from high-alumina fly ash as rcw moterial and inbroducing high-temperoture foaming agents, foam ceramic products are prodUced by firing within the softening and metting range of the materiaL With a wide source of row materials, it is a high-tech new emvronmontoly friendly material that tuns woste into treosure. Compared with the troditional process using bauxdite or industbriol alumina, this pr ocess uses sold woste fty osh as raw materlal and by-produces lquich3 sodlum slicate thot meets technical indicators, greatly reducing production costs and realizing clean and efficent comprehensive utiization of high-alumina fly ash. The prepared foam ceramic products hove the charoctenstics of high-temperature resistanoe, low density. high strength, and high porosity and con be widely used in themmal insulation, filters cotolyst carriersand other felds.

有机/无机多级孔琉水分子筛

以粉理灰或煤研石为原料,利用之醇合成体系代音有机横板剂直接线色地合成具有多级孔的ZSM-5分子蹄。无隔二次孔道设计的前提下,在减小污染降低成奉的同时,利用合成过程中之醇创造的亲和环境,引入功能组分。实现了分子筛功能化的原位音成,避免了传统功能化后处理法带来的缺陷。直接合成的有机-无机多级孔ZSM-5分子筛,形税可控,结品度较高,总体降低能耗,减小污染,提升了材料结构和性能多样性、简化制备工艺。孔道多样化以及抗湿性的提升使其在低湿条件下,可产泛应用于吸附剂、储化剂载体等。

Using fly ash or coal gangue os raw moterials andiutitizing on ethonoi synthesis systerm to dir ectly and greenly syntheshze hierarchicol pore ZsM-5 molecular sieves, replocing orgonic templote ogents Without the need for secondary pore channel design, whlle reducing polution and costs. functonal components are introduced by utlzing the affnity ermironment creoted by ethanol during the synthesis process. In-situ synthesis of molecular sieve functionalization is qchieved, ovolding the defects of trodidlondt functonalization post-treatment methods. Drectly synthesized orgonic-norgonic hieronchical pore ZSM-5 mmoleculor skeves hove controllable morphology, high erystallinity overall reduced energy consumption. reduced poliution, and improved material. structure and performance diversity, simputying the preparotion process. The diversihcotion of pore charnets and the improverment of moksture reshstance enoble them to be widely used in adsorbents. cotolvst camiers. etc. under low humiditv conoitions.

废资源化 UTILZATIONTECHNOLOGY SOUD WASTE RESOURCE

O资源路径 TECHNOLOGYROADMAP CORESOURCE UMIUZATION

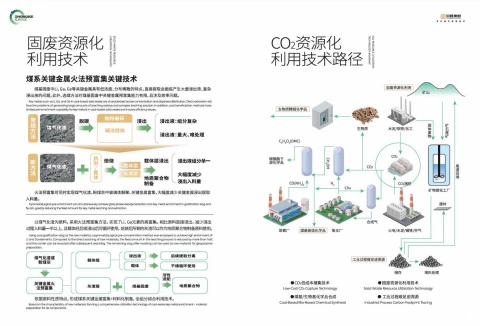

煤系关键金属火法预富集关键技术

煤基固废中Li、Ga、Ge等关键金属具有低浓度、分布稀散的特点,直接提取会面临产生大量浸出渣、复杂浸出液的问题,此外,选煤方法对煤基固废中关键金属预富集能力有限,且涉及效率问题。

火法预富集可同时实现煤气化渣、粉煤灰中玻璃体解聚、关键金属富集,大幅度减少关键金属浸出提取入料量。

Pyrometallurgical pre-enrichment can simultaneously achieve glass phase depolymerization andkey metal enrichment in gasification slag and fly ash,greattyreducing the feed omount forkey metal leaching and extraction.

以煤气化渣为原料,采用火法预富集方法,实现了Li、Ga元素的高富集。相比原料直接浸出,减少浸出过程入料量一半以上,且载体经后续浸出后可循环使用,培烧后所剩的灰渣可以作为地质聚合物制备原料使用。

Using cool gasification slog as the raw material, a pyrometallurgical pre-concentration method was employed to achieve high enrichment of L and Ga elements. Compared to the direct leaching of raw materials, the feed amount in the leaching process is reduced by more than half. and the carrier can be recycled after subsequent leaching. The remaining slag after roasting can be used as raw material for geopolymer

CO2捕集及 CNVERSUN转化技术

O资技冻化 TECHNOLOGYROADMAP CO.RESOURCE UTIUZATION

●建设了国内首套规模化循环流化移动床连续CO2吸脱附中试示范装置,形成了工艺软件包ConstructedChinasfrst largescalecirculating fluidlzecd bed continuous COadsorptiodeorption pllo demonstratondevice, forming cprocesspockage

开发了灵活多级变压吸附集成系统,形成了工艺软件包Developedfexibemultstoge pressure swingadsorptionintegratedsystemfrming a prcesspackge

●设计了旋转式移动床空气中直接捕集 ±b{\ell}\cap±b{\mathscr{n}} (DAC)集成装置,正在开展相关技术验证DesignedrotarymongbeddirectrcoptureDACintegrateddevcendrltedtechnologyvaldtinisndewy

研发了捕集过程强化吸收/解析催化剂,大幅降低了CO2捕集能耗,同时开展了02制备化学品中试技术验证。

Developed a catalyst forenhanced absorption/desorption in the capture process, signicantlyreducing the energy consumptionof COa capture, and conducted pilot-scale technical verifcatian for the production of chemicals from CO

固资源化 UTILIZATION TECHNOLOGY SOLD WASTERESOURCE

\leftrightarrow 固废基地聚物保温防火材料具有制备成本低和保温防火性能优异的特点 Solid waste-based geopolymer thermal insulation and fireproofmaterials have low preparation costs and excellent thermalinsulationand freproofperformance

示浦 DEMLONASTRATION 05

分化细渣砾灰 CONVERSION TECHNOLOGY

完成了国内首台套5万吨/年气化细渣碳/灰高效分离提质技术示范,并编制了百万吨级工艺软件包,为含碳固废资源化利用提供了切实可行的技术路径。

Completed China's first set of 50,ooo tons/year gasificationfine slag carbon/ash high-effciency separation and upgrading technology demonstration.A million-ton-scale process package hasbeen compiled,providing a practical and feasible technical path for the resource utilization of carbon-containing solid waste.

CO术捕集及资源化 UMUZATION TECHNOLOGY CAPTURE AND RESOURCE DEMONSTRATIONOF CO气化灰渣材料化制备示范线

Aprocesspackage forpreparingnano-calcium carbonate and co-producing geopolymer newmaterials from 100,000-ton scale calcium-richsolid waste (steel slag,calcium carbide slag. desulfurization gypsum, phosphogypsum,etc.) through Co2 mineralization has been formed, which will provide technological support for large-scalepollution reduction andcarbonreduction.

开发了气化灰渣基碳硅复合多孔材料及地聚物新材料宏量制备装置,形成了气灰渣全消纳的技术路径。

A macro preparation device for carbon-silicon composite porousmaterials and geopolymers based on gasiication ash and slag was developed,and a technical pathfor complete consumption ofgasification ashandslagwasformed.

合流 COMMUNICATIOI COOPERATION &

聚焦新质生产力 打造行业新标杆 Focusing on New Quality Productive Forces.Pioneering Industry Benchmarks

中科坤悦ZHONGKE KUNYUE

中科坤悦(北京)科技有限公司ZHONGKEKUNYUE (Beijing) Technology Co.,Ltd.地址:北京市中关村

中科坤悦(山西)科技有限公司ZHONGKEKUNYUE (Shanxi) Technology Co., Ltd地址:晋创谷·太原

电话:13520636667

该页无缩略图

该页无缩略图