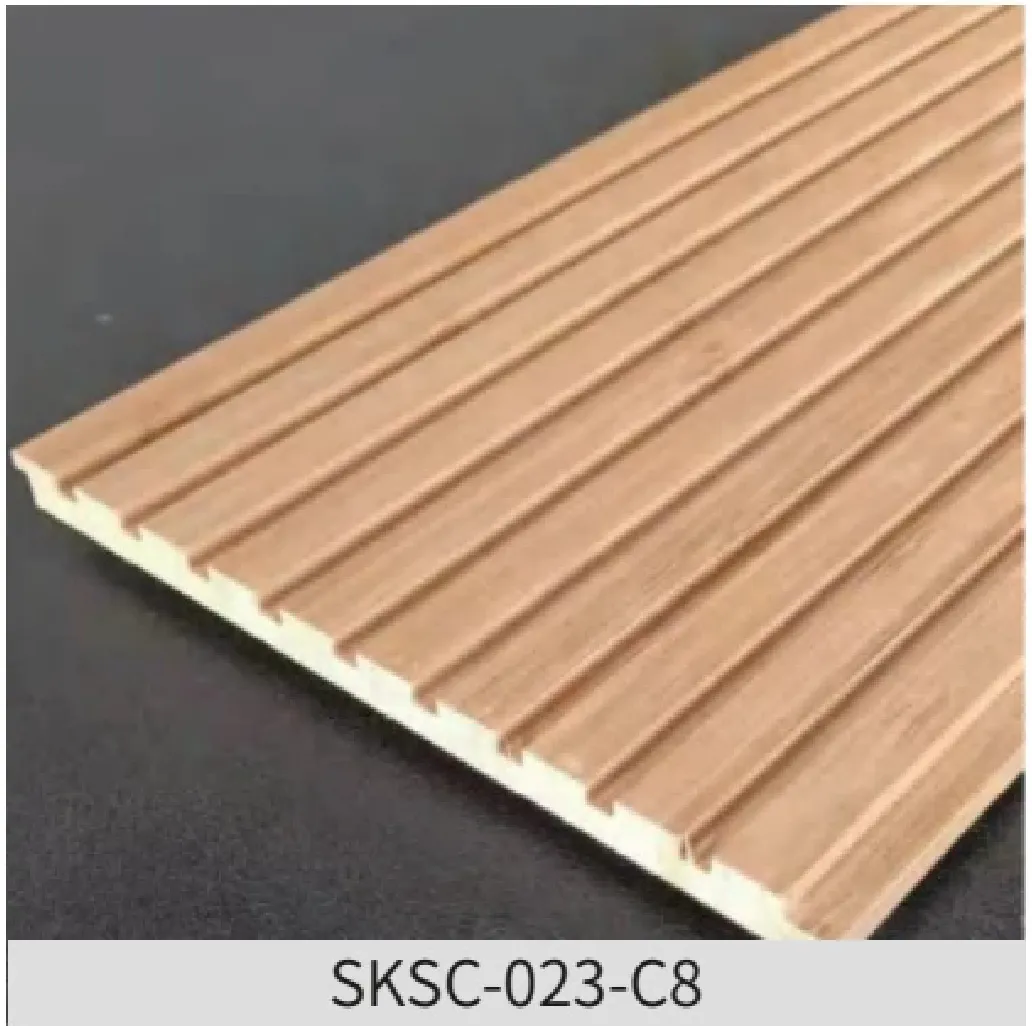

| Technical specifications | |

| Bending radius for a 5 mm board | about 50 mm |

| Bending radius for a 8 mm board(4mm panel*2glued) | about100mm |

| Bendingradiusfora 16 mm board(4mm panel*4glued) | about 300 mm |

| Longitudinal elasticity fora 5 mm board | 210 N/mm2 |

| Cross elasticity for a 5 mm board | 6300N/mm2 |

| Thicknesstolerance | +/- 0,35 mm |

| Length tolerance | +/- 5 mm |

| Widthtolerance | +/- 5 mm |

| Tolerance in squaring | 2 mm/m |

| Moisture content (at delivery) | 8-12% |

| Reaction to fire(EN 13501-1) | D-s2,d0 - Dfl-s1 |

| Thermal conductivity (EN 12664) | 0,12 W * (m k)-1 |

| Density(EN323) | about 400kg/m3 |

Bonding (formerly called IF20) is made with urea-formaldehyde glue(UF) and is in compliance with theprovisionsoftheEN314-2standard.

Aftersuitabletreatmentinviewofresistancetohumidity,theboardcompliestoClass 1 requirementsfortheuse of boards in dry environments(EN 636-1).

Class 2(formerly called AW100 or MR),foruses subject to exposure to moisturevariation,can also beproduced uponrequest withmelaminegluing.

Usage and storage instructions

-Store the panels lying flat in a clean, shaded, dry place.

- Panels should be transported on a hard flat surface. Single panels can be rolled, but should not remaininthispositionforlongperiods.

-Donot expose the panelto sudden changes in humidity,temperature,and also protect it from Sunlight.

- Glue the panels while they are brought into the desired shape. When the glue is dry, panel wil retain itsshape.

- High Pressure Laminate or paper-backed veneer can be applied during the initial curving process, or in asecond step.

- Any wood glue can be used.

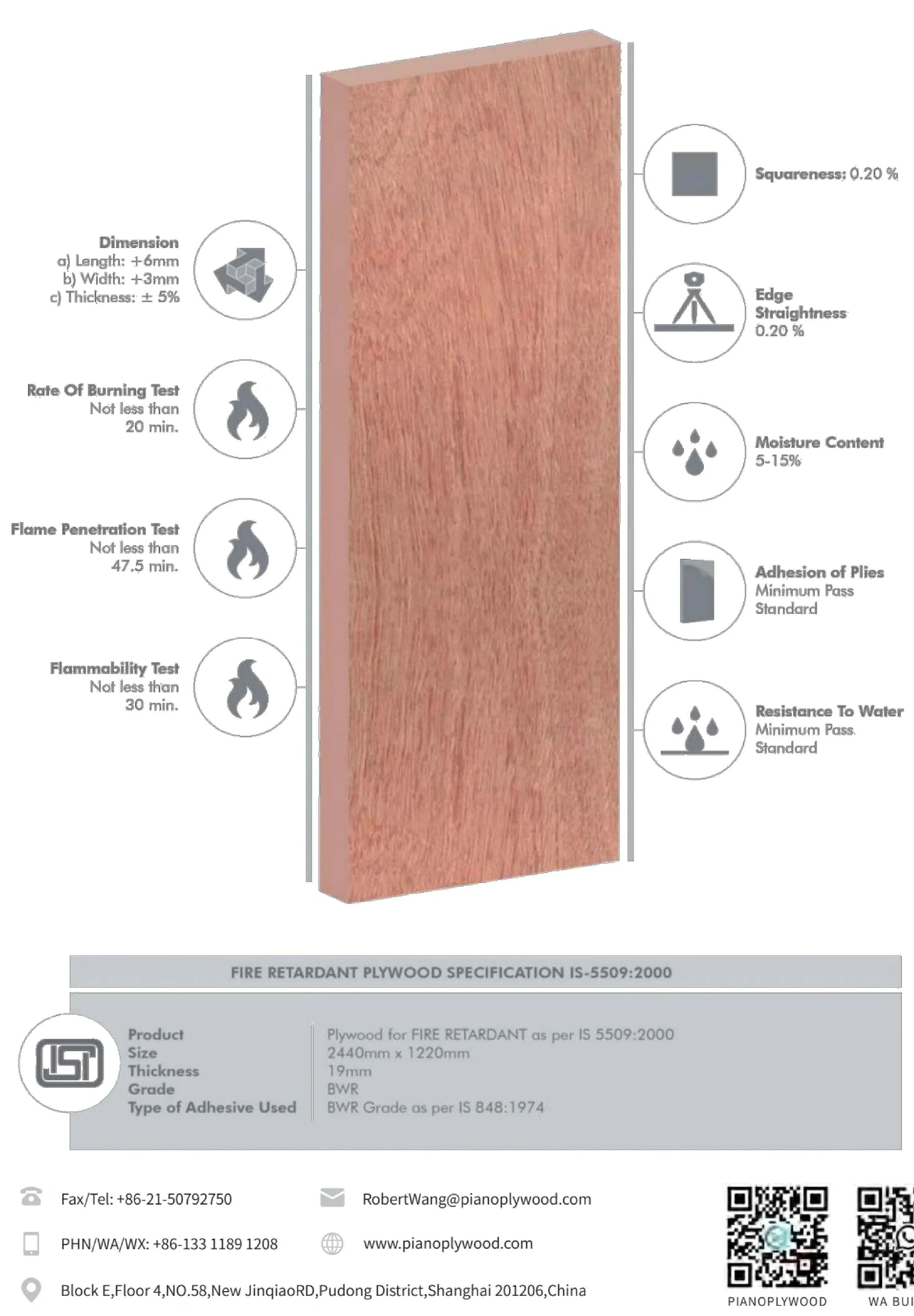

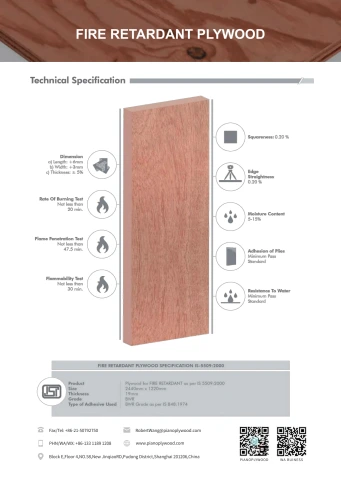

PRODUCT IFIRERETARDANTPLYWOOD

·The protectivecharis non-hygroscopic in nature.It willnot affect thehardware elementsthatmay corrode due tomoistureaffinityofcommonchemicals.

·The chemicalis non-leachable hence thereisnoloss of theretardant chemicals invery adverse conditions.Does not affect painting oroverlaying.

·No significant effect on the strength properties (adhesive bonding) compared to normal grade (BWR, BWP) plywood

·ltsslowrate of burning provides sufficient time forthe firetobe extinguished.

·Unlikecommonply,ArchidplyFiresafeplycreatesabarrieragainstfire,duetoitsslowerfirepenetratingrate ·Nailandscrewholdingpropertyisnotaffected.

·Tensile and bending strength remain unaffected,asthechemical does notreact with wood.

| Size: | 1220*2440mm,1250*2500mm. |

| Thickness: | 4mm-30mm |

| Face/Back: | Peelingveneer,Sliceveneer,Engineeredveneer,Melamine film,HPL |

| Standard | CE,FSC,CARB,ISO9001,SGS,IS5509,EN13353-2008,GB/T 18101-2013,A1,EN6361,ASTME84,GB18580-20171. |

| Application | Furniture,Cupboard,Goods shelves,Packing&Boxes,Wallboard,Decoration,FireProne Area |

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

Technical Specification

| Classification according toEuropeanStandard EN 13501-1 | |||||

| Definition | Construction products | Floorings | |||

| non-combustilematerials | A1 | Al, | |||

| A2-s1d0 A2-s2d0 A2-s3d0 | A2-s1d1 A2-s2d1 A2-s3d1 | A2-s1d2 A2-s2d2 A2-s3d2 | A2H-S1 | A2m-52 | |

| combustible materials-verylimitedcontribution tofire | B-s1do B-s2d0 B-s3d0 | B-s1d1 B-s2d1 B-s3d1 | B-s1d2 B-s2d2 B-s3d2 | B-s1 | B-s2 |

| combustible materials-limited contribution tofire | C-s1do C-s2d0 C-s3d0 | C-s1d1 C-s2d1 C-s3d1 | C-s1d2 C-s2d2 C-s3d2 | Cn-51 | C-s1 |

| combustible materials-medium contribution to fire | OPIS- D-s2d0 D-s3d0 | D-s1d1 D-s2d1 D-s3d1 | D-s1d2 D-s2d2 D-s3d2 E-d2 | D-s1 | Dg-s1 |

| combustible materials-highly contribution to fire | E | Ea | |||

| combustible materials-easilyHammable | F | F | |||

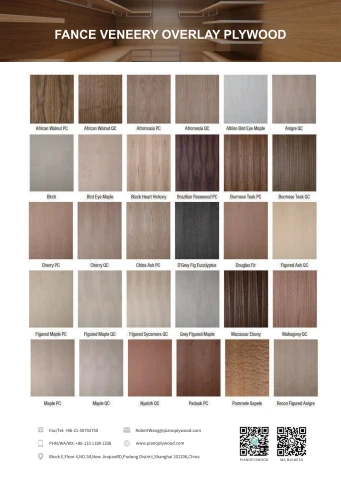

PRODUCT FANCEVENEERYOVERLAYPLYWOOD

Top qualityfancyveneer overlaid plywood baseboard same as common plywood(poplar, eucalyptus,pine,birch,hardwood,combi core and soon),face/back with allkinds of sliced fancy veneersfromsolidwoods(ash,birch,cheery,walnut,teak,beech,oak,elmandsoon).

Advantage

Application

Uniformmaterialquality,dense lamellarstructure,thesurfaceflat andsmooth,noteasyto deformation,stableperformance, theedgelightandsmooth,not easytocollapseedgeandlayered, non-toxic,tasteless,non-radiation andgoodairpermeability.Good thermal insulationperformance, notaging and strong adhesion.

FormatSize: 1220\*2440mm,915\*1830mm,1250\*2500mm,1500\*3000mm(customized accordingtorequirements).

Thickness: 3.0mm -30mm (customized according to requirements).

Core: Common plywood (poplar,Eucalyptus,pine,birch,hardwood,combi core)

RawMaterial: Natural Veneer-red oak/white oak/sapele/beech/okoume/Burma teak/recon/bamboo silk.

Standard CE,FSC,CARB,ISO 9001,SGS,BS 1088,AS/NZS 2272,PEFT,EN 314,BS EN 350,ISO 14001.

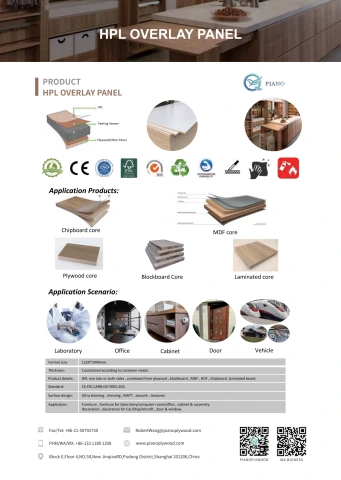

Face/back One side orboth sides overlaid bymelaminefilm,melamine film with allkinds of grains(single color,wooden, stone and so on).

Glue: WBP(melamine),phenolic.

Application Use where appearance of plywood isnot important forinterior application as furniture.

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

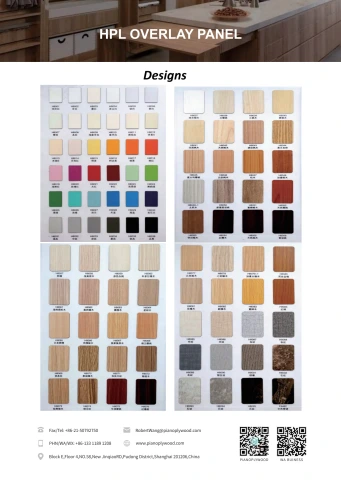

Designs

Designs

Each piece of Polyester Panels are made by experience applicator by hand. Polyester Resin is mixed and applied by experienced applicatorto create a master piece of its own.Our applicatortakesprideineverypiecetheyproduce.

GUARANTEED ^{100%} PERESIN SCRATCH,HEAT,WATERAND CHEMICALRESISTANCE

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

POLYESTER FILM DESIGN

Polyester Plywood with Textured Paper

PolyesterParticleBoard

Construction:

Blockboard

Block board ismadeup of a core of softwood strips.The stripsareplacededgetoedgeandsandwichedbetween veneersofhardwood.Asingleveneeronbothsidesis known as3-ply.A doubleveneer on both sides is called 5-ply.Thesandwichisthenglued underhighpressure.

Stripsof softwood glued togetherand faced with veneers Does'notsplit easily

·Veneeredblockboard isakindof fancyblockboardbasedecorativepanel.Theblockboard alsocan laminatetheHPL,melaminepaper.Butthemostimportantistheselectingofrightbaseboard and face&backveneersforthiskindofveneeredblockboard.Wesuggesttochoosethegoodquality blockboard asthebaseboard.And thenfacethewoodveneersforthefaceandback of theblockboard.

1.Face:peeling/slice/Engineeredwoodveneer/HPL/Melamine film/decorativeepaper/polyesterfilm/UVCoating/HDF/plastic.

2.1-2layerspeelingveneer

3.Core:laminated solid wood strips,poplarcore,paulownia core, malacca core,hardwood core,fir core,pinecore.

4.1-2layerspeelingveneer

5.Back:same asperno.1,orblancelayer.which can makethe fullsheetsofveneeredblockboardhaveabetterstability

| Formatsize: | 1220*2440mm,1500*3000mm |

| Thickness: | 15to40millimeters. |

| Material: | |

| Standard | CE,FSC,CARB,ISO9001,SGS,BSEN635,BSEN636,BSEN13986. |

| Type: | FarEastern Lightweight,BB Birch Blockboard,AshFaced Blockboard,OakFaced Blockboard,Chinese Blockboard. |

| Application | Furniture,shelves,doors,panelingandpartitions. |

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

| TECHNICALSPECIFICATIONS(IS:1659) | |||

| 1 | TEST Dimensional Changescaused | ISIREQUIREMENT | ObservedValue |

| a) b) c) | byHumidity Changes,mm from65%RHto90%RH from65%RHto40%RH LocalPlaneness Attheextremerangeof humidity | +1mm Max -1mm Max. <1/150 Node-laminationatthe extremerangeofhumidity | +0.50mm -0.55mm <1/175 No de-lamination observed |

| 2 | Adhesionoftheplies | Minimumpassstandard | Excellent |

| 3 | Resistancetowater (72hoursboiling) | No de-laminationafter72 hoursboiling | No de-lamination |

| 4 | ResistancetoMicroorganisms | Noappreciablesignof separationatedges. | No separation atedges |

| 5 6 | ModulusofElasticity ModulusofRupture | Min.5000N/sq.mm Min.50N/sq.mm | 6050N/sq.mm 61N/sq.mm |

Application

| FormatSize: | 1220*2440mm,1250*2500mm(customizedaccordingtoneeds). |

| Thickness: | 5.0mm-30mm(customizedaccordingtoneeds). |

| Standard | CE,FSC,CARB,ISO9001,SGS,BS1088,AS/NZS2272,PEFT,EN314,BSEN350,ISO14001 |

| Core: | Larch,Poplar,hardwood,hardwoodcombi,birch,eucalypts,asyourrequirement |

| Grade: | FurnitureGrade. |

| Face&back | Embossed larchforface,larchforback |

| Application | Structure,decoration,furniture&handicraft,woodenhouse. |

RobertWang@pianoplywood.com

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

n1 BAMBOODECKING

BAMBOOSOFFIT&CLADDING

D3 BAMBOOFLOORING

N4

BAMBOOFURNITURE

BAMBOOCRAFT

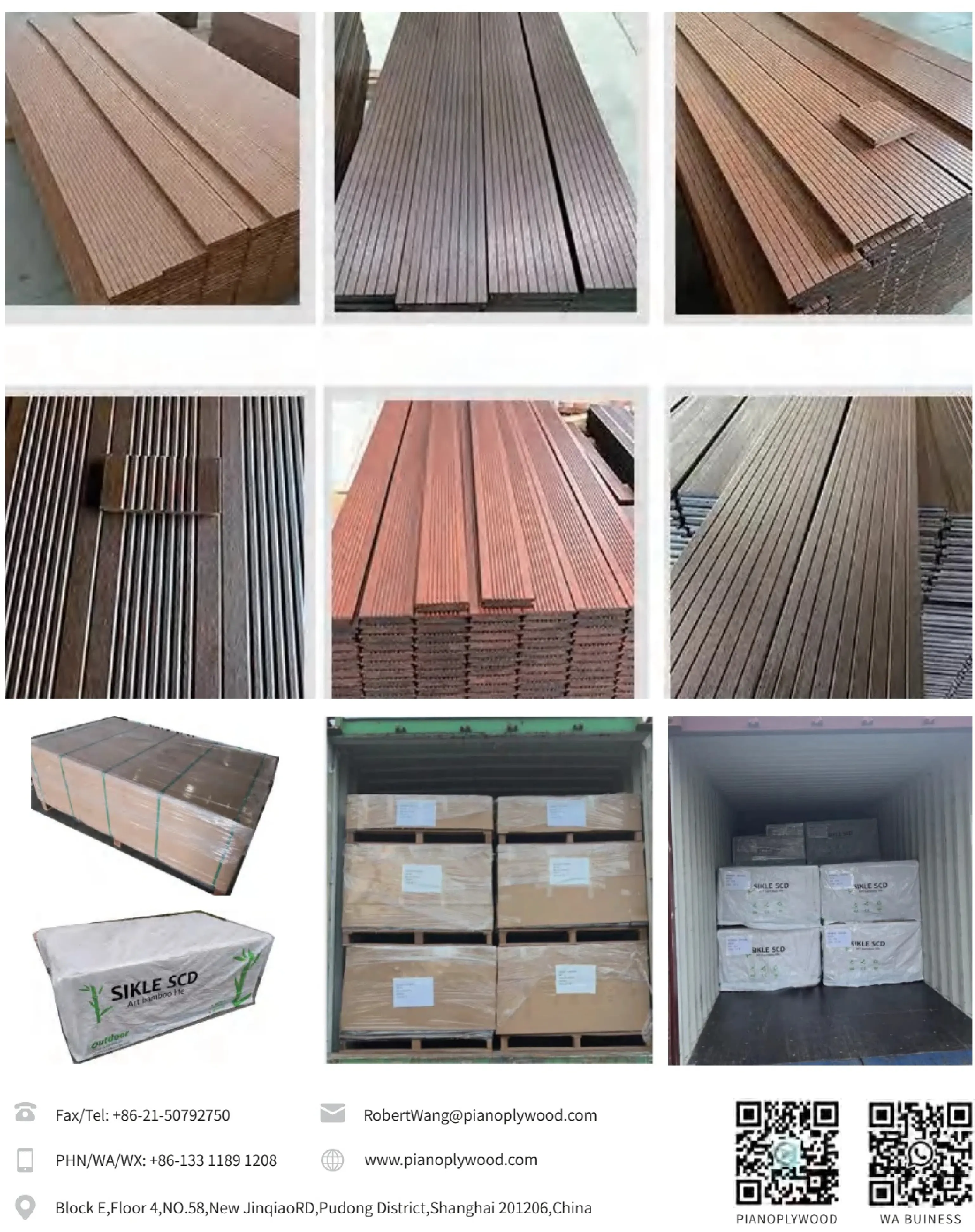

BAMBOO DECKING

PRODUCTINTRODUCTION&APPLICATIONS

OUTDOOR BAMBOO DECKING

Outdoor Bamboo Decking uses a unique high-temperature, high-intensity compression process to remove sugar molecules from the bamboo, making the bamboo free of fungi and microorganisms.

Thissolves the problem of anti-corrosion and insect resistance andby changing the water-absorbing groups inside the bamboo,there by solving theproblem of deformation andcracking,the material density,hardness and flexural strengthare much higherthan any wood.

Outdoor Bamboo Decking remains straight and very stable even after many yearsofinstallation.

Bamboo Decking is the ideal outdoor material.

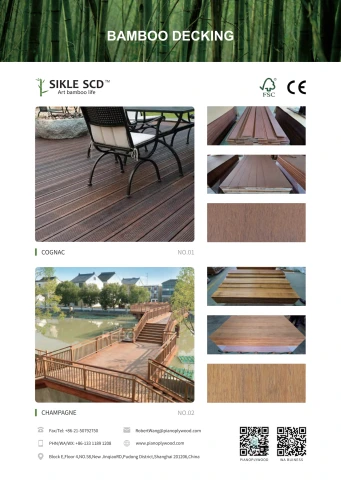

| LENGTH: | 1860/2000/2500/3000/4000mm |

| WIDTH: | 68/140mm |

| THICKNESS: | 18/20/30/40mm |

| DENSITY: | 1200kg/cm3 |

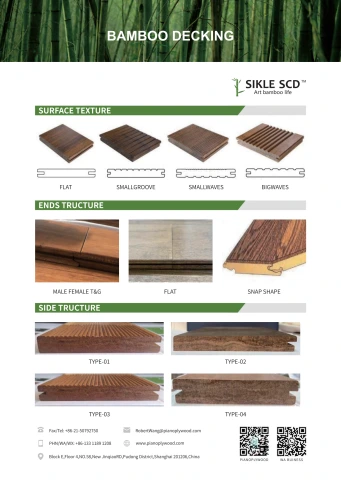

| SURFACE: | Flat/SmallGroove/SmallWaves/BigWaves |

| APPLICATION: | Privatecountyard/garden/park/seaside/hotel/ swimmingpool |

BAMBOO

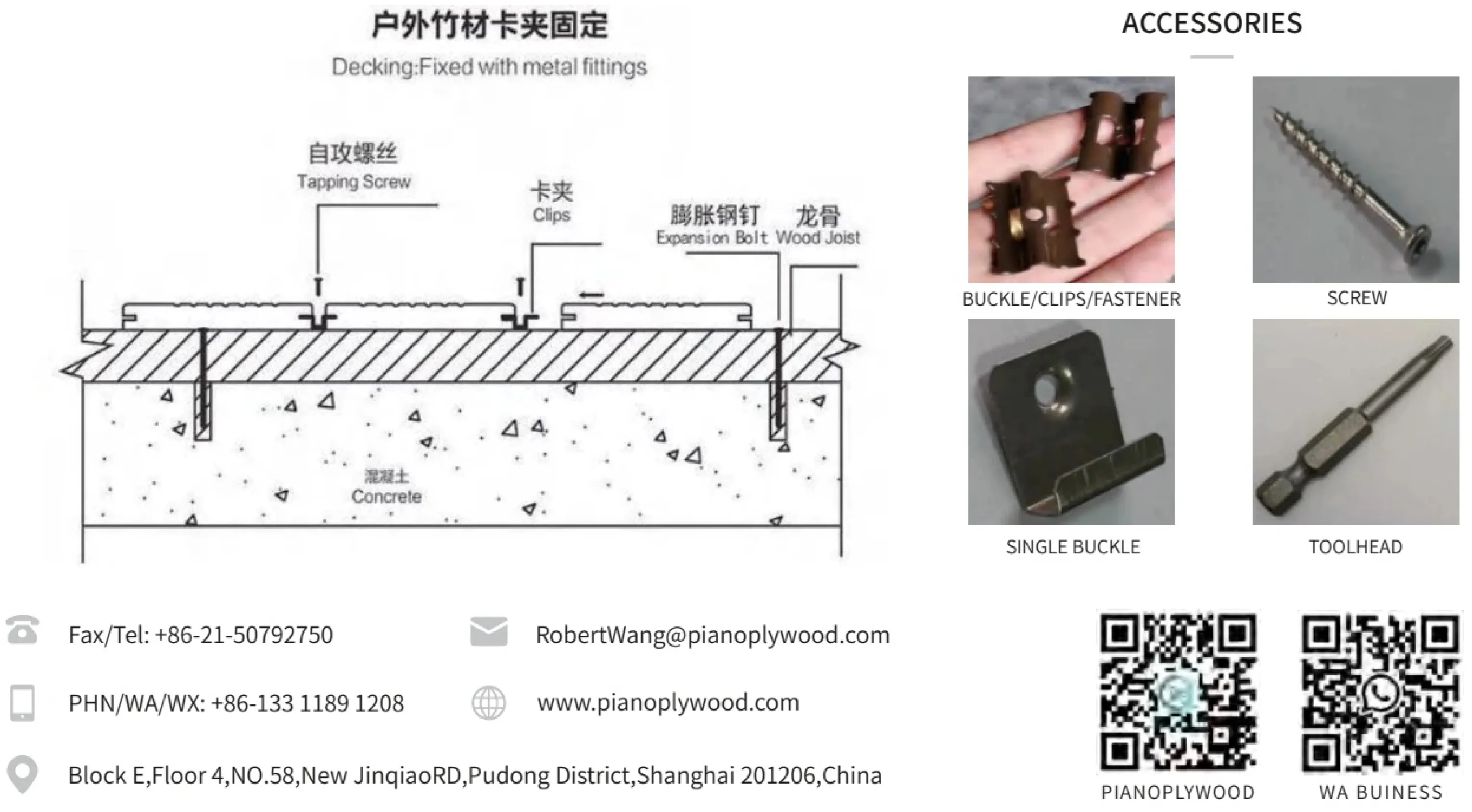

EACHBOXOFACCESSORIESHAS:

·1000pcs 5MM new brownplastic sprayed fasteners;

·1000pcs 35MM plum blossom countersunk head self tappingscrewssuitableforwoodenkeel;

· 6pcs plum blossom screwdriver heads.

· 21pcs 7.5MM unilateral black plastic sprayed clips;

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

| CONTAINER | SLOTTINGMODE | SHEETS | SQM | WEIGHT |

| 20GP | Unilateralgroove | 3273 | 852 | 22000Kgs |

| Slotonbothsides | 208 | 54 |

| NUMBER | MODEL | PHOTOS | ENDSTRUCTURE |

| NO.01 Cognac NO.02 Champagne NO.03 Whiskey | Flat+SmallWaves | ||

| NO.07Irish(moka) | Flat+BigWaves |

INSTALLATIONPROCEDURESFOROUTDOORDECKING

1.PREPARATIONOFCONCRETEFLOOR

Level the ground to be laid onthe outdoorfloor and pour10-15CM thickconcrete.

2.FIXING THE KEEL

Useanimpactdrillorelectrichammertopunchholes(about) 10{*}12\mathsf{mm}^{\star}60\mathsf{mm}) ontheconcretefloor,oneevery40cm(lessthan40cm is counted as 40cm),drive pine wood plugs into the holes,and place them on thekeel.Punch holes on the keel,the hole diameteris the sameasthe steel nailsused,and thehole distance isthesame astheground holedistance.Then use 4^{\star}80 roundnailstodrive throughthekeel.

Thecleardistancebetweenthekeelsisnotmorethan 500mm anditisrecommendedtouse 400\mathsf{mm} fortheinterview;theinstallation ofthekeels should bekept horizontal to ensure that the entire decking installation is completed and the buckles are flat and therearenoobviousbumps;

3.FIXINGMETHOD

1)Sweep fixing method (forfloors with grooves on the side):When installing the first board, use flat-head stainless steel self-tappingscrews 4^{\star}45 onthe outward sideata 45-degree angle,and therest canbe connected and fixed withfloorconnectors:specific the fixing method isasfollows:firstly insert one side ofthe floorfastener(face up,the hole is perpendiculartothe ground) into the slot of thefirstfloor,and thenpresstheside ofthesecond flooragainst thefirstrow of planks.Fasteners,insert thesecond rowof floor

fasteners on theotherside ofthe second floor(the numberof floorfastenersisthe sameas the keel),and then insert the third decking board...Install in sequence, about 4-8 pieces, and then use self-tapping screws to pass through the decking fasteners to fix the decking on thekeel; the decking is installed in this order.The installation method of the last piece at the end is the same as the first piece, and the outward side is fixed with a 45-degree oblique screw from the rose screw.

2)Direct fixing method(forfloors without grooves onthe side):Thefirst stepistoplacethe outdoorfloorintherequired position, and thenpunch 2-3holes evenly onthe board surface alongthe centerof thekeel,with a diameterof4mm and a depth of 35- 40\mathsf{mm} ;inthesecondstep,useadrillwithadiameterof 10\mathsf{mm} toreamthetopofthefloor,andthedepthis 2{-}3mm inthethird step,use 5^{\star}50 stainlesssteel countersunkhead screwstodrill thedrilled holestofirmthefloor.

FINISHED PRODUCTAND PACKAGING

BAMBOO MAINTENANCEOFOUTDOORFLOORS

1.MAINTENANCE CYCLE

The first maintenance is carried out in the third month afterthe paving iscompleted;thesecondmaintenanceiscarriedoutintheninth month afterthepaving is completed.Subsequent maintenancecan be carriedoutonceayear.

2.MAINTENANCE METHOD

Choose a sunny day afterthefloor is dry (it is recommended to carry out atleastoneweekof continuoussunnyweather). 1) Checkfortightness:Checkthefloorforloosenessand reinforce loosefloors.

2)Cleaning and Sweeping:Cleanup all corrosion,dust,dirt,oil,coal ash andotherimpurities onthefloorsurface.Before protection,the surface mustbecompletely cleaned;clean the debris around thefloor andthekeeltomakethedrainagesmooth.

3)Sanding: Use a soft steel brush to sand and clean the floorsurface.

4) oiling:Use thefirst coat of wood wax along thelength ofthebrush.

5) Grinding: Use 80-100 grit sandpaper to polish the surface burrs.

6)Second oiling: Use a brushto applythe second wood wax oilalong

thelength.

3.PRECAUTIONS

1) Immediately after use,put rags,brushes, and waste into metal containers to keep them clean and hygienic. 2)The second pass of wood wax oil is carried out 12 hours afterthe first pass of brushing.

BAMBOO OUTDOORFLOORCAREANDMAINTENANCE

If wecancarryoutregularmaintenanceinaccordancewithour company'smaintenanceprecautions,wehavereasontobelievethat ourcustomerscanuseheavybamboo outdoor"newfloors"everyyear.

Toreiterate,thefirst maintenance should be carried outinthe third month aftertheinstallation of theheavybamboofloorof ourcompany;the second maintenance should be carried outinthe ninthmonth aftertheinstallationiscompleted.Subsequentmaintenancecanbe carriedoutonceayear.

Fax/Tel:+86-21-50792750

PHN/WA/WX: +86-133 1189 1208

RobertWang@pianoplywood.com www.pianoplywood.com

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

BAMBOO BENEFITS

SIKLE bamboois one of the fastest growing plants on earth.Although giant bamboo is formally not a wood buta grass, it has excellent hardwood-like characteristics.Discoverthe benefits that SIKLE Bamboo products canoffer in your project!

NATURALBEAUTY

The most striking feature of SIKLE Bamboo products is certainly its natural beauty.The beautiful natural grain gives bamboo a distinct design appearance.Combined with the vast choice of different styles,configurations and colors,there is alwaysa SIKLE bamboo product available which will match yourpreferences.

HIGH TABILITY

Due to the composition of individual strips,bamboowill shrink and swelless than most solid wood species, providing a very stable solution.Thismeansthat unique and intriguing solutions and creationscanbedeveloped.

ENDLESSRESOURCE

Bamboo is an‘endless’resource.It growsfasterthan any other plant;up to1 meter per day!Each yearthe 4-5 year stems are harvested,providing room forthe youngerbamboo to growto maturity.During growth SIKLE bamboo absorbs more {\mathsf{C O}}^{2} than is released during production.All solid SIKLE bamboo products arethereforeguaranteed \mathsf{C O}^{2} neutraloverthecomplete lifecycle.

HARD&DURABLE

Bamboo,afterprocessing,isvery hard and durable.This means SIKLE Bambooflooring and decking canbeused in heavy duty applications, where conditions such as high-traffic are expected. As well as this, several products are more than suitable for being usedoutdoors.

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

HIGHSTABILITY

Due to the composition of individual strips,bamboo will shrink and swell lessthan most solid wood species, providing a very stable solution.This means that unique and intriguing solutions and creations can be developed.

HEALTHYANDFIRERESISTANT

SIKLEBamboo products are also a healthy choice as they are antistaticand anti-allergic.Furthermore,theyhaveverylow emissions of harmful voCs(VolatileOrganicCompounds).Due to thehigh density,several SIKLEBamboo products fulfill stringentfire safetyrequirements andSIKLEhastested almost the full range of bambooproducts.

AWIDEVARIETYOFCHOICE

Combined withthevastchoiceofdifferentstyles,configurationsandcolors,thereisalwaysaSIKLEBambooproduct availableto match the desired needs.From commercial to domestic use and industrial applications to unlimited solutions, SIKLE SCD has both theknowledgeandexpertisetohelpyouprogress.

UPTO20YEARSGUARANTEE

Developingthebestbambooproductisonlypossiblethrough continuous attention foreach detail during production.The Chinese SIKLEteam was created just for that.Only because of theirdailyeffort,aSIKLEBambooproduct isvery different from a standard Chinese bamboo product.And in the unlikely case that something was overlooked,customerscan count onourfull supportandguaranteeupto20years.

RobertWang@pianoplywood.com www.pianoplywood.com

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

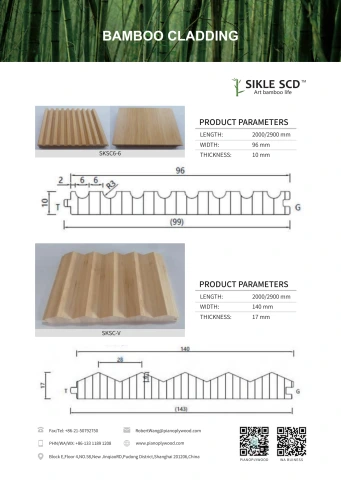

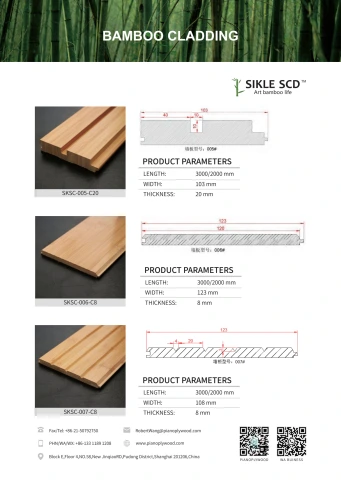

PRODUCT BAMBOO CLADDING

PRODUCTPARAMETERS

| LENGTH: | 5800/2900 mm |

| WIDTH: | 140 mm |

| THICKNESS: | 18 mm |

OUTDOOR

Shall have anti-skid grade of R11

INDOOR Flame retardant grade reaches Bf1

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

PRODUCT BAMBOO CLADDING

PRODUCTPARAMETERS

| LENGTH: | 5800/2900 mm |

| WIDTH: | 140 mm |

| THICKNESS: | 18 mm |

PRODUCT BAMBOOSOFFIT

PRODUCT BAMBOOSOFFIT

PRODUCTPARAMETERS

| LENGTH: 5800/2900mm | |

| WIDTH: | 135mm |

| THICKNESS: | 15 mm |

| APPLICATION: | Interiordecorative,exteriorbuilding |

| forprivatehouse,school,museum, hotel,projectsolution |

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

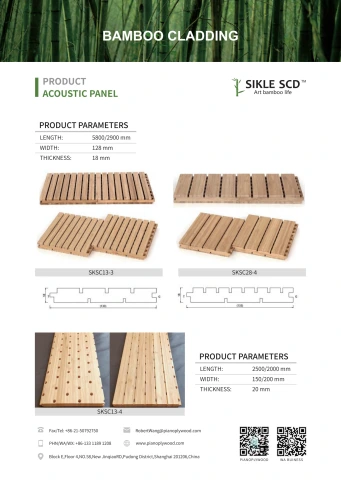

PRODUCT ACOUSTICPANEL

| LENGTH: | 5800/2900 mm |

| WIDTH: | 128 mm |

| THICKNESS: | 18 mm |

PRODUCTPARAMETERS

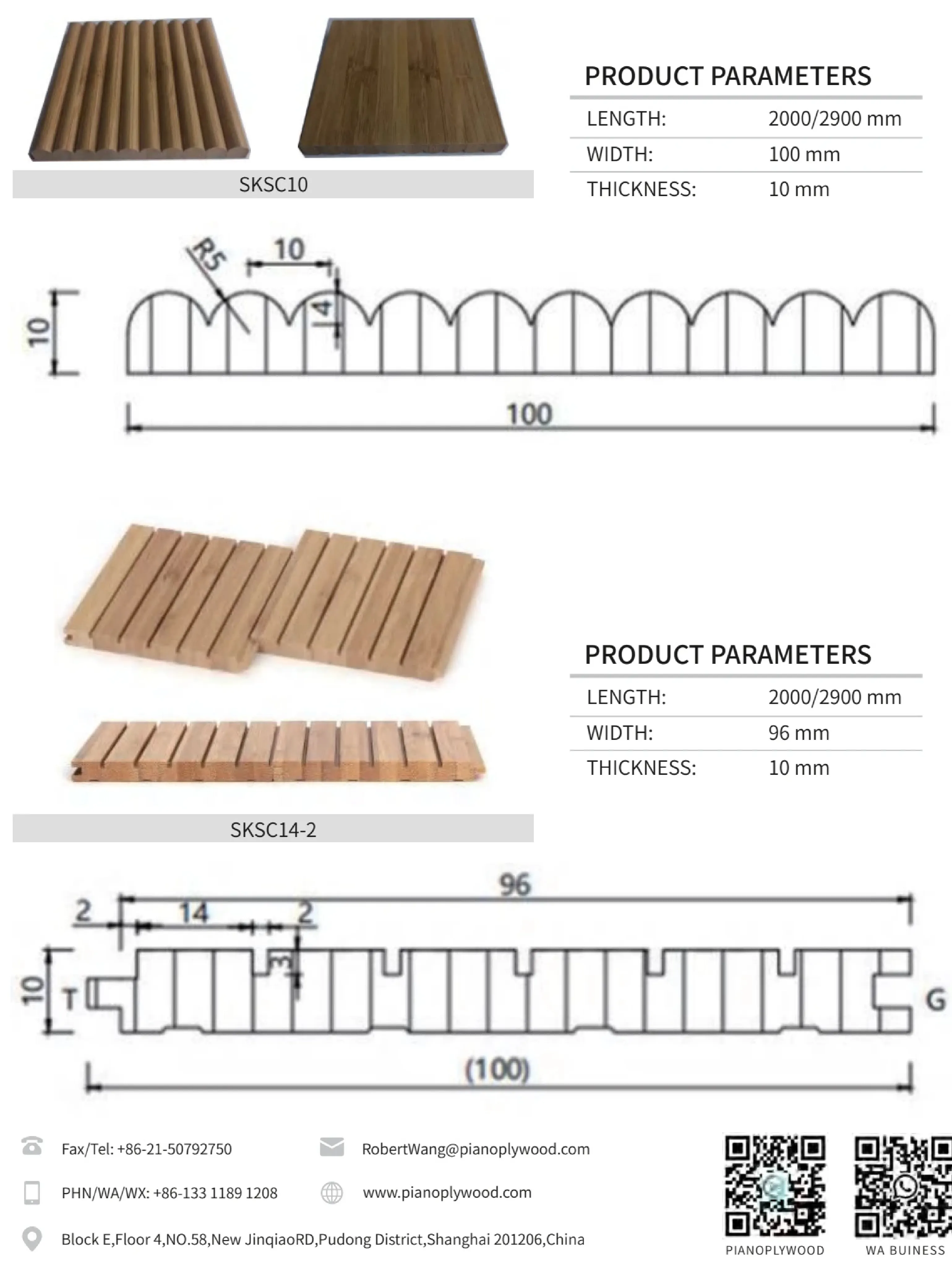

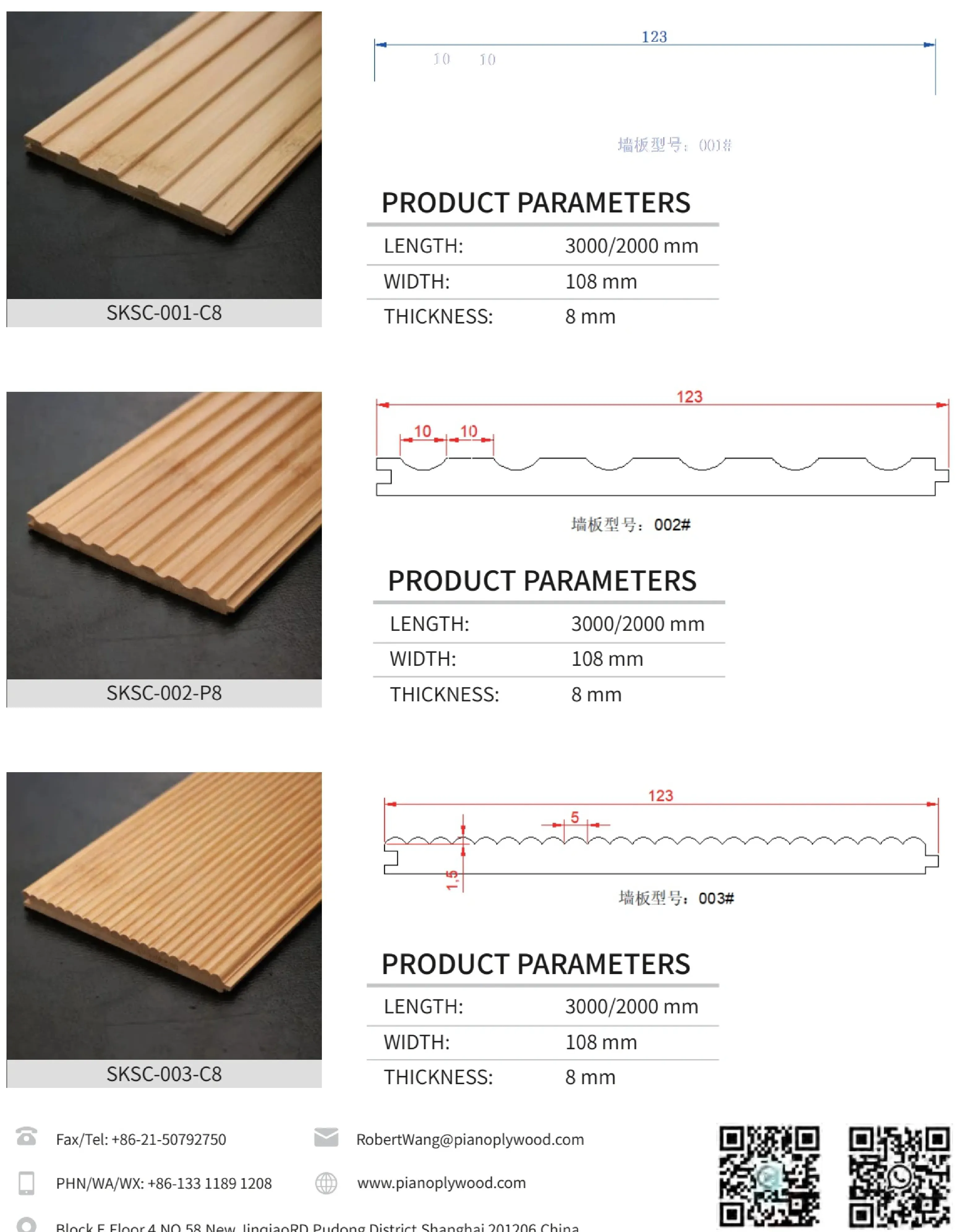

| LENGTH: | 3000/2000 mm |

| WIDTH: | 123 mm |

| THICKNESS: | 8mm |

PRODUCTPARAMETERS

| LENGTH: | 3000/2000 mm |

| WIDTH: | 123 mm |

| THICKNESS: | 8r mm |

PRODUCTBAMBOO EDGECLOSINGLINE

| LENGTH: | 2000 mm |

| WIDTH: | 40 mm |

| THICKNESS: | 40 mm |

| PRODUCTPARAMETERS | |

| LENGTH: | 2000 mm |

| WIDTH: | 30 mm |

| THICKNESS: | 15 mm |

| PRODUCTPARAMETERS | |

| LENGTH: | 2000mm |

| WIDTH: | 15 mm |

| THICKNESS: | 15 mm |

MAINTENANCEOFSOFFITAND CLADDING

1.MAINTENANCE CYCLE

Dust thedust on thesurface of thewallboard witha dustereverytwoweeksoronemonth,whichcaneffectivelyreduce theadsorption of dust onthesurfaceandprolong theusetime.

2.MAINTENANCEANDCLEANINGMETHOD

The film on the surface of the wallboard has a certain degree of air permeability,and the stain must be cleaned up intime to prevent it from being adsorbed to theinside of the wallboard fora long time.Thebest time to decontaminate isto scrub the dirt in time before the dirt is completely dry.The order of cleaning the dirt should be from the outside to the inside,rinse with an absorbent sponge block,do not usehot water.Remember not to use sharp objects,so as not to scratch the surface of thewallboard.

1)il stains:For local oil stains,pourthe neutral detergent stock solution ona towel towipe; for large areas of oil stains, increase the

numberofwipes,and thenwipedrywithwater.

2)Rust: Dilute it with a neutral detergent, leave it on for 10 minutes, and then remove it with water.

3)Ink,coffee,juice:Dilutewithneutral detergent,thenremovewithwater.

4)Nail polish, paint, glue: First carefully remove the dirt,then wash it with alcohol, and remove it after the dirt softens.

For thewallsnearthebalconiesand windows,whenstrong lightmust be irradiated,the curtains shouldbe drawnto avoid discoloration andfadingcausedbylong-termsunlight.

BAMBOO FEATURE

Bamboo isn't a plant, it's a lifestyle. Eco-friendly & sustainable, exactlymeetingtheconceptofsocialdevelopment,endless possibilitiestomakeyourideacometrue.

BAMBOO APPLICATION

Interiordecorative,exteriorbuilding,school,museum,hotel, projectsolution.

Block E,Floor4,NO.58,New JinqiaoRD,Pudong District,Shanghai 201206,China

BAMBOO BAMBOOBEAMAPPLICATION

HAITANGBAYMARRIOTTTAIKANGRESORTHOTEL

COMPLETION TIME: Aprill 2022

USING MATERIALS: B1Flameretardant andweatherresistantreconstituted

SIZE: 200^{\star}40^{\star}6200\sfmm

APPLICATIONPOSITION: Architectural curtain wall decorationfacadeHotelpublicarea walls and floorsRestaurant bamboo wovenfacadeGuestroom public area walls, handrails, elevator lobbieselevator cars

该页无缩略图

该页无缩略图