复合材料科学与工程

3? 2 纤维缠绕层模型

对于复合材料层ꎬ其螺旋层及环向层的总厚度

t

fα和 t

fβ采用网格理论[12]进行确定:

t

fα

=

R?Pb

2?k?σfb?cos

2

α

t

fβ

=

R?Pb

2?σfb

2 - tan

2

( α)

ì

î

í

ï

ï

ï

ï

ïï

(1)

式中:R 为铝合金内衬筒身段半径ꎻPb 为压力容器

的最小设计爆压ꎻσfb为纤维的许用强度ꎻk 为螺旋缠

绕的应力平衡系数ꎬ其取值范围为 0? 65 ~ 0? 85ꎻα 为

筒身段螺旋缠绕角度ꎮ

本文中纤维缠绕压力容器的工作压力为 35 MPaꎬ

其设计依据为 GB / T 35544—2017«车用压缩氢铝内

衬碳纤维全缠绕气瓶»ꎮ 水压试验压力为 52? 5 MPaꎬ

最小设计爆破压力为 78? 75 MPaꎮ 纤维单层厚度为

0? 2 mmꎬ纤维许用强度为 1950 MPaꎬ计算所得缠绕

铺层方案为:[±112

/ 906

/ ±112

/ 906

/ ±11 / 902 ]ꎮ

对于纤维缠绕层的建模ꎬ为了描述纤维缠绕压

力容器在封头段的变角度变厚度特性ꎬ使用 Python

脚本结合三次样条厚度预测公式ꎬ对封头段厚度进

行建模ꎬ封头段两个带宽内的厚度计算方法如下:

t(r)=m1

× r

0 + m2

× r

1 + m3

× r

2 + m4

× r

3

(2)

其中系数 m1 、m2 、m3 和 m4 求解方法如下:

m1

m2

m3

m4

é

ë

ê

ê

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

ú

ú

=

1 r0

r

2

0

r

3

0

1 r2b

r

2

2b

r

3

2b

0 1 2r2b 3r

2

2b

π(r

2

2b

-r

2

0 )

2π

3

(r

3

2b

-r

3

0 )

π

2

(r

4

2b

-r

4

0 )

2π

5

(r

5

2b

-r

5

0 )

é

ë

ê

ê

ê

ê

ê

ê

êê

ù

û

ú

ú

ú

ú

ú

ú

úú

-1

×

tR?πR?cosα0

/ (m0?b)

mR?nR

π

arccos

r0

r2b

æ

è

ç

ö

ø

÷ - arccos

r0

+ b

r2b

æ

è

ç

ö

ø

÷

é

ë

ê

ê

ù

û

ú

ú?tR?M

mR?nR

π

r0

r2b

r

2

2b

- r

2

0

-

rb

r2b

r

2

2b

- r

2

b

æ

è

çç

ö

ø

÷÷?tR?M

Vconst

ì

î

í

ï

ï

ï

ï

ï

ï

ï

ï

ïï

ü

þ

ý

ï

ï

ï

ï

ï

ï

ï

ï

ïï

(3)

式中ꎬVconst为两个带宽处的纤维体积ꎬ其计算方法

如下:

M =1 / arcsin

(R

2 - r

2

0 ) - (R

2 - r

2

b) + b

2 [ ]

2R { }

(4)

Vconst

=∫

rb

r0

2πr?

mR?nR

π

?arccos

r0

r

æ

è

ç

ö

ø

÷?t

p dr +∫

r2b

rb

2πr?

mR?nR

π

? arccos

r0

r2b

æ

è

ç

ö

ø

÷ - arccos

r0

+ b

r2b

æ

è

ç

ö

ø

÷

é

ë

ê

ê

ù

û

ú

ú?tR?Mdr

(5)

其中:ri 为缠绕位置的平行圆半径ꎻr0 为极孔半径ꎻrb

为一个带宽处的平行圆半径ꎻr2b为两个带宽处的平

行圆半径ꎻtR 为缠绕层在筒身段的厚度ꎻnR 为筒身

段螺旋缠绕单层数ꎻmR 为筒身段纱片数ꎻn0 为极孔

处的缠绕单层数ꎻm0 为极孔处的纱片数ꎮ

在两个带宽外区域的纤维厚度计算方法为:

t(r)=

mR?nR

π

arccos

r0

r2b

- arccos

(r0

+ b)

r2b

é

ë

ê

ê

ù

û

ú

ú?tR?M

(6)

通过 Python 脚本可以将纤维缠绕层的每一层

厚度分布描绘出来ꎬ下一层纤维的厚度分布则通过

上一层纤维的外轮廓确定ꎮ 所得纤维层厚度分布如

图 6 所示ꎮ

图 6 纤维缠绕层厚度及角度分布示意图

Fig? 6 Schematic diagram of thickness and

angle distribution of filament wound layer

碳纤维缠绕层在封头处的角度分布通过测地线

缠绕公式来确定:

α(r)=arcsin(r0

/ r) (7)

2021 年第 12 期 43

???????????????????????????????????????????????

基于精细化模型的纤维缠绕压力容器失效行为及容积特性影响因素分析

3? 3 有限元计算模型

对于轴对称模型ꎬ为提高计算效率及精度ꎬ一般

不采用全模型进行计算ꎬ本文采用 1 / 2 模型进行后

续的有限元计算分析ꎬ最终用于有限元计算模型如

图 7 所示ꎮ

图 7 压力容器计算模型

Fig? 7 Pressure vessel calculation model

由于纤维缠绕层模型是逐层建立的ꎬ可以在层间

插入黏性层ꎬ用以表征缠绕层间的分层损伤情况ꎮ 铝

合金内衬及纤维缠绕层均采用 C3D8R 单元(八结点

线性六面体单元ꎬ采用减缩积分及沙漏控制)ꎬ部分

网格过渡区域采用 C3D6 单元(六节点单元)ꎬ其中

黏性单元采用 COH3D8 单元(八结点三维黏结单元)ꎮ

3? 4 材料属性

纤维缠绕压力容器内衬材料为 6061 ̄T6 铝合

金ꎬ增强纤维材料为 T700CS ̄12K 碳纤维ꎬ树脂材料

为 EW ̄60D 环氧树脂ꎬ采用湿法缠绕后固化成型工

艺ꎮ 其材料性能如表 1、表 2 所示ꎮ 内聚力单元材

料属性如表 3 所示ꎮ

表 1 铝合金材料力学性能参数

Table 1 Mechanical properties of aluminum alloy

参 数 数 值

弹性模量 E/ GPa 74.1

泊松比 μ 0.28

屈服强度/ MPa 281

屈服极限/ MPa 340

密度/ kg?m

-3 2800

表 2 T700 碳纤维/ 环氧树脂力学性能参数

Table 2 Mechanical properties of T700 carbon fiber/epoxy resin

参 数 数 值

纵向拉伸模量 E1

/ GPa 134

横向拉伸模量 E2

=E3

/ GPa 7.42

面内泊松比 μ12

= μ13 0.28

面外泊松比 μ23 0.3

面内剪切模量 G12

=G13

/ GPa 3.71

层间剪切模量 G23

/ GPa 4.79

纵向拉伸强度 Xt

/ MPa 1950

纵向压缩强度 Xc

/ MPa 1250

横向拉伸强度 Yt

/ MPa 74

横向压缩强度 Yc

/ MPa 180

面内剪切强度 S / MPa 50

密度 ρ / kg?m

-3 1680

表 3 黏性层力学性能参数

Table 3 Interfacial cohesive properties

界面参数 数 值

弹性模量 E/ GPa 3.0

泊松比 μ 0.35

拉伸强度 Sn

/ MPa 30

剪切强度 Ss

= St

/ MPa 45

拉伸断裂韧性 Gnc

/ N?mm

-1

0.28

剪切断裂韧性 Gsc

/ N?mm

-1

0.79

3? 5 边界条件

纤维缠绕压力容器爆破压强计算模型的边界条

件主要包括图 8(a)所示循环对称边界条件、图 8(b)

所示侧剖面在柱坐标系(RTZ)下的环向对称约束、

图 8(c)所示下端面的固定约束及图 8(d)所示铝合

金内衬内表面的压强载荷ꎮ 具体约束的施加如图 8

所示ꎮ

图 8 边界条件施加示意图

Fig? 8 Schematic diagram of boundary condition imposition

44 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

3? 6 渐进损伤计算方法

渐进损伤计算方法通过 Hashin 失效准则判断

纤维和基体的失效情况ꎬ结合 Quads 准则对层间黏

性单元层进行失效判断ꎮ 计算过程包括应力计算、

失效判断和材料退化三个部分ꎮ 通过应力计算结合

Hashin 失效判据对各单元的损伤情况进行判断ꎬ若

出现损伤则对相应单元的材料进行刚度折减ꎬ其刚

度折减规则参照 Camonho 材料退化模型[13]

ꎬ具体退

化准则如表 4 所示ꎬ当整个模型的刚度折减累积到

一定程度时整个结构出现结构失效ꎮ 通过结构失效

对应的载荷来判断爆破压强的大小ꎮ 渐进损伤计算

流程图如图 9 所示ꎮ

表 4 材料性能退化准则

Table 4 Criteria for material degradation

失效模式 退化准则

基体开裂 E22

= 0.2E22 ꎬ G12

= 0.2G12 ꎬ G23

= 0.2G23

基体挤裂 E22

= 0.4E22 ꎬ G12

= 0.4G12 ꎬ G23

= 0.4G23

纤维拉伸

破坏

E11

= 0.07E11 ꎬ E22

= 0.07E22 ꎬ E33

= 0.07E33 ꎬ G12

= 0.07G12

G13

= 0.07G13 ꎬ v12

= 0.07v12 ꎬ v13

= 0.07v13 ꎬ v23

= 0.07v23

纤维压缩

破坏

E11

= 0.14E11 ꎬ E22

= 0.14E22 ꎬ E33

= 0.14E33 ꎬ G12

= 0.14G12

G13

= 0.14G13 ꎬ v12

= 0.14v12 ꎬ v13

= 0.14v13 ꎬ v23

= 0.14v23

图 9 渐进损伤计算流程图

Fig? 9 Computational flow chart

Hashin 失效准则包括纤维的拉伸与剪切破坏、

纤维的压缩与剪切破坏、基体拉伸与剪切破坏以及

基体压缩与剪切破坏四种ꎬ在 Abaqus 中以结果状态

定义变量来表示ꎬ具体计算方式如下:

纤维拉伸及剪切破坏(σ11≥0):

σ1

Xt

æ

è

ç

ö

ø

÷

2

+ α

τ12

S12

æ

è

ç

ö

ø

÷ +

τ13

S13

æ

è

ç

ö

ø

÷

é

ë

ê

ê

ù

û

ú

ú

2

≥1 (8)

纤维压缩及剪切破坏(σ11<0):

σ1

Xc

æ

è

ç

ö

ø

÷

2

≥1 (9)

基体拉伸及剪切破坏(σ22

+σ33≥0):

σ2

+σ3

Yt

æ

è

ç

ö

ø

÷

2

+

τ

2

12

+ τ

2

13

S

2

12

+

τ

2

23

-σ2?σ3

S

2

23

≥1 (10)

基体压缩及剪切破坏(σ22

+σ33<0):

Yc

2S23

æ

è

ç

ö

ø

÷

2

- 1

é

ë

ê

ê

ù

û

ú

ú?

σ2

+σ3

Yc

+

σ2

+σ3

2S23

æ

è

ç

ö

ø

÷

2

+

τ

2

12

+ τ

2

13

S

2

12

+

τ

2

23

-σ2?σ3

S

2

23

≥1

(11)

4 结果与讨论

4? 1 纤维缠绕压力容器有限元结果分析

通过渐进损伤计算结果可以看出纤维缠绕压力

容器出现结构失效的主要原因是筒身段环向层纤维

发生大面积拉伸断裂损伤[14 ̄16]

ꎮ 且压力容器发生结

构失效时ꎬ螺旋缠绕层出现了大面积基体拉伸损伤ꎬ

纤维缠绕层间也出现了较大面积的分层现象ꎮ 图

10 给出了压力容器发生结构失效时各损伤结果ꎬ为

了使结果呈现得更加直观ꎬ将纤维拉伸损伤结果中

最内层的螺旋层在结果显示时去除一半ꎬ从实际损

伤结果可以看出ꎬ导致内胆出现爆破的主要原因是

筒身段环向缠绕纤维出现大面积损伤ꎬ与纤维拉伸

损伤结果一致ꎻ与此同时ꎬ各纤维缠绕层间及纤维层

与铝合金内衬脱开ꎬ与层间损伤计算结果[17 ̄20]一致ꎮ

图 10 结构发生失效时压力容器损伤结果

Fig? 10 The damage result when structure failed

最终爆破压力值通过筒身段的载荷 ̄径向位移曲

线来确定ꎬ通过渐进损伤计算出的精确爆压为曲线

发生位移突变的点ꎬ即本文所设计的压力容器计算

爆压为 73? 5 MPaꎬ与实际打爆结果误差为 3? 3%ꎮ 载

荷位移曲线如图 11 所示ꎬ图中也将实际测量值与计

算值进行了对比ꎮ 图 12 为测点 2 和测点 5 应变实

2021 年第 12 期 45

???????????????????????????????????????????????

基于精细化模型的纤维缠绕压力容器失效行为及容积特性影响因素分析

际测量结果与计算值的对比ꎬ由于实际应变片手动

铺贴与预设值有偏差ꎬ最终误差在 10%以内ꎮ

图 11 载荷 ̄径向位移曲线

Fig? 11 Load ̄radial displacement curve

图 12 载荷 ̄应变曲线

Fig? 12 Load ̄strain curve

4? 2 压力容器容积特性分析

本文对不同容积与不同设计爆压的压力容器进

行了容积特性分析(容积特性系数可以用来评价压

力容器的承载性能ꎬ其值越高代表压力容器的承载

性能越优异)ꎮ 研究对象为试验常用的 6? 8 L、9 L

及 18 L 压力容器ꎬ在筒身段长径比(本文中用以表

示容器筒身长度和筒身直径的比值)、封头段椭球比

及极孔半径与筒身段半径比值(下文中简称为开口

比)、设计方法及参数一致的前提下ꎬ分别计算了各

型号压力容器在设计爆压为 20 MPa~120 MPa 的容

积特性系数 PV / Wꎻ为了更加精确地描述碳纤维缠

绕层的承载性能ꎬ同时计算了纤维层容积特性系数

PcV/ Wcꎬ其中 Pc 为压力容器总体爆压与铝合金内衬

爆压之差ꎬV 为压力容器容积ꎬWc 为纤维缠绕层重

量ꎮ 其计算结果如图 13 所示ꎬ从计算结果可以看出:

①容积特性 PV/ W 随着容积的增加而增大ꎬ并随着设

计爆压的增加而增大ꎻ②容积特性 PcV / Wc 随着容积

的增加而增大ꎬ并随着设计爆压的增加而略微减小ꎮ

(a)6.8 L

(b)9.0 L

(c)18 L

图 13 不同型号压力容器容积特性变化曲线

Fig? 13 Volume characteristic curve of pressure

vessels of different types

在此基础上研究了长径比(筒身段长度与筒身

段直径的比值) 对容积特性系数 PcV / Wc 的影响ꎮ

在气瓶内胆容积、椭球比、开口比及设计方法、参数

一致的前提下ꎬ计算了容积为 9 L、椭球比为 2 、开

口比为 0? 19 的压力容器不同长径比对容积特性的

影响ꎮ 计算的 5 组压力容器的尺寸参数如表 5 所

示ꎬ其容积特性系数 PcV / Wc 变化曲线如图 14 所示ꎮ

46 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

表 5 内衬尺寸参数

Table 5 Dimension parameters of lining

参 数

数 值

1 2 3 4 5

长径比 i 1.5 2 2.5 3 3.5

筒身段直径/ mm 179.8 166.8 156.8 148.8 142.4

短半轴长/ mm 63.5 59.0 55.4 52.6 50.3

筒身段长/ mm 269.7 333.5 392.0 446.7 498.3

图 14 容积特性随长径比变化曲线

Fig? 14 Volume characteristic curve with aspect ratio

从计算结果可以看出ꎬ容积特性系数 PcV/ Wc 随

着长径比的增大而减小ꎮ

5 结 论

本文通过对纤维缠绕压力容器的三维扫描实验

对比厚度预测公式ꎬ给出了一种高精度的有限元建

模方法ꎮ 基于该方法进行了小型压力容器的设计计

算ꎬ并通过水压爆破实验进行验证ꎮ 结果表明:

(1)三次样条厚度预测方法能准确预测测地线

纤维缠绕层在封头处的厚度分布情况ꎮ

(2)采用缠绕层逐层建立并在层间插入黏性层

单元结合 Hashin 失效判据的渐进损伤计算方法ꎬ能够

精准、全面以及直观地判断压力容器的各种损伤情况ꎮ

(3)压力容器水压试验结果为 76 MPaꎬ与有限

元计算结果误差为 3? 3%ꎮ 位移应变结果与实际测

量值误差在 10%以内ꎬ表明通过载荷位移曲线破坏

位置的位移突变确定爆破压强是合理的ꎮ

(4)对于Ⅲ型压力容器ꎬ可以通过增大设计爆

压提高容器的容积特性系数ꎻ且相同容积压力容器

的容积特性随着长径比的增加而减小ꎮ

参考文献

[1] REN M Fꎬ CHANG Xꎬ XU H Yꎬ et al. Trans ̄scale analysis of com ̄

posite overwrapped pressure vessel at cryogenic temperature[J]. Com ̄

posite Structuresꎬ 2016ꎬ 160: 1339 ̄1347.

[2] 杨文刚ꎬ 李文斌ꎬ 林松ꎬ 等. 碳纤维缠绕复合材料储氢气瓶的研

制与应用进展[J]. 玻璃钢/ 复合材料ꎬ 2015(12): 99 ̄104.

[3] ZU Lꎬ XU Hꎬ WANG H Bꎬ et al. Design and analysis of filament

wound composite pressure vessels based on non ̄geodesic winding[J].

Composite Structuresꎬ 2019ꎬ 207: 41 ̄52.

[4] ZHANG Qꎬ XU Hꎬ JIA X L. Design of a 70 MPa type Ⅳ hydrogen

storage vessel using accurate modeling techniques for dome thickness

prediction[J]. Composite Structuresꎬ 2020ꎬ 236: 111915.

[5] 王华毕ꎬ 程硕ꎬ 祖磊ꎬ 等. 复合材料储氢气瓶的纤维厚度预测与

强度分析[J]. 复合材料科学与工程ꎬ 2020(5): 5 ̄11.

[6] 王亮. 基于微观力学分析的复合材料储氢容器强度与寿命研究

[D]. 杭州: 浙江大学ꎬ 2016.

[7] NEBE Mꎬ SORIANO A. Analysis on the mechanical response of com ̄

posite pressure vessels during internal pressure loading: FE modeling

and experimental correlation[ J]. Composites Part B: Engineeringꎬ

2021ꎬ 212: 1359 ̄8368.

[8] LIU P Fꎬ CHU J Kꎬ HOU S Jꎬ et al. Micromechanical damage mod ̄

eling and multiscale progressive failure analysis of composite pressure

vessel[J]. Computational Materials Scienceꎬ 2012ꎬ 60: 137 ̄148.

[ 9] RAMIREZ J P Bꎬ HALM Dꎬ GRANDIDIER J Cꎬ et al. 700 bar type

Ⅳ high pressure hydrogen storage vessel burst simulation and exper ̄

mental validation[ J]. International Journal of Energyꎬ 2015ꎬ 40:

13183 ̄13192.

[10] 矫维成ꎬ 王荣国ꎬ 刘文博ꎬ 等. 纤维缠绕复合材料压力容器封

头厚度预测[J]. 复合材料学报ꎬ 2010ꎬ 27(5): 116 ̄121.

[11] HASHIN Z. Failure criteria for unidirectional fiber compositer[ J].

Journal of Applied Mechanicsꎬ 1980ꎬ 47(2): 329 ̄334.

[12] 陈汝训. 纤维缠绕壳体设计的网格分析方法[ J]. 固体火箭技

术ꎬ 2003ꎬ 26(1): 30 ̄32.

[13] Lessard L B. Comparison failure in laminated composites containing

an open hole[D]. Stanfordꎬ USA: Stanford Universityꎬ 1991.

[14] WANG Qꎬ LI TONGꎬ WANG BOꎬ et al. Prediction of void growth

and fiber volume fraction based on filament winding process me ̄

chanics[J]. Composite Structuresꎬ 2020ꎬ 246: 112432.

[15] CAMANHO P Pꎬ MATTHEWS F L. A progressvie damage model

for mechanically fastened joints in composite laminates[J]. Journal

of Composite Materialsꎬ 1999ꎬ 33(24): 2248 ̄2280.

[16] 杨帆. 冲击作用下复合材料气瓶损伤形态与剩余强度[D]. 大

连: 大连理工大学ꎬ 2019.

[17] LIU P Fꎬ CHU J Kꎬ et al. Micromechanical damage modeling and

multiscale progressive failure analysis of composite pressure vessel

[J]. Computational Materials Scienceꎬ 2012ꎬ 60: 137 ̄148.

[18] 王晓宏ꎬ 张博明ꎬ 刘长喜ꎬ 等. 纤维缠绕复合材料压力容器渐

进损伤分析[J]. 计算力学学报ꎬ 2009ꎬ 26(3): 446 ̄452.

[19] 安文奇ꎬ 路智敏ꎬ 赵飞ꎬ 等. 金属内衬碳纤维复合材料压力容器

壳体的有限元分析[J]. 内蒙古工业大学学报(自然科学版)ꎬ

2017ꎬ 36(4): 18 ̄23.

[20] RAFIEE Rꎬ TORABI M A. Stochastic prediction of burst pressure

in composite pressure vessels [ J]. Composite Structuresꎬ 2017ꎬ

185: 573 ̄583.

2021 年第 12 期 47

???????????????????????????????????????????????

基于分布式光纤传感技术的 CFRP 板变形监测研究

DOI:10? 19936 / j? cnki? 2096 ̄8000? 20211228? 007

基于分布式光纤传感技术的 CFRP 板变形监测研究

何建平1

ꎬ 沈 锋2

ꎬ 张世海3

(1? 大连理工大学 土木工程学院ꎬ 大连 116024ꎻ 2? 江苏飞博尔新材料科技有限公司ꎬ 盐城 224700ꎻ

3? 南阳理工学院 土木工程学院ꎬ 南阳 473001)

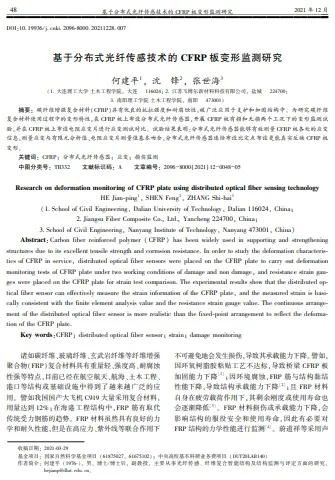

摘要: 碳纤维增强复合材料(CFRP)具有优良的抗拉强度和耐腐蚀性ꎬ被广泛应用于支护和加固结构中ꎮ 为研究碳纤维

复合材料使用过程中的变形特性ꎬ在 CFRP 板上布设分布式光纤传感器ꎬ开展 CFRP 板有损和无损两个工况下的变形监测试

验ꎬ并在 CFRP 板上布设电阻应变片进行应变测试对比ꎮ 试验结果表明:分布式光纤传感器能够有效测量 CFRP 板各处的应变

信息ꎬ测量应变与有限元分析值、电阻应变片测量值基本吻合ꎬ分布式光纤传感器连续布设比定点布设更能真实反映 CFRP 板

变形ꎮ

关键词: CFRPꎻ 分布式光纤传感器ꎻ 应变ꎻ 损伤监测

中图分类号: TB332 文献标识码: A 文章编号: 2096-8000(2021)12-0048-05

Research on deformation monitoring of CFRP plate using distributed optical fiber sensing technology

HE Jian ̄ping

1

ꎬ SHEN Feng

2

ꎬ ZHANG Shi ̄hai

3

(1? School of Civil Engineeringꎬ Dalian University of Technologyꎬ Dalian 116024ꎬ Chinaꎻ

2? Jiangsu Fiber Composite Co.ꎬ Ltd.ꎬ Yancheng 224700ꎬ Chinaꎻ

3? School of Civil Engineeringꎬ Nanyang Institute of Technologyꎬ Nanyang 473001ꎬ China)

Abstract:Carbon fiber reinforced polymer ( CFRP) has been widely used in supporting and strengthening

structures due to its excellent tensile strength and corrosion resistance. In order to study the deformation characteris ̄

tics of CFRP in serviceꎬ distributed optical fiber sensors were placed on the CFRP plate to carry out deformation

monitoring tests of CFRP plate under two working conditions of damage and non damageꎬ and resistance strain gau ̄

ges were placed on the CFRP plate for strain test comparison. The experimental results show that the distributed op ̄

tical fiber sensor can effectively measure the strain information of the CFRP plateꎬ and the measured strain is basi ̄

cally consistent with the finite element analysis value and the resistance strain gauge value. The continuous arrange ̄

ment of the distributed optical fiber sensor is more realistic than the fixed ̄point arrangement to reflect the deforma ̄

tion of the CFRP plate.

Key words:CFRPꎻ distributed optical fiber sensorꎻ strainꎻ damage monitoring

收稿日期: 2021 ̄03 ̄29

基金项目: 国家自然科学基金项目 (61875027ꎬ 61675102)ꎻ 中央高校基本科研业务费项目 (DUT20LAB140)

作者简介: 何建平 (1976 ̄)ꎬ 男ꎬ 博士/ 博士后ꎬ 副教授ꎬ 主要从事光纤传感、 纤维复合智能结构及结构监测与评定方面的研究ꎬ

hejianp@dlut? edu? cnꎮ

诸如碳纤维、玻璃纤维、玄武岩纤维等纤维增强

聚合物(FRP)复合材料具有重量轻、强度高、耐腐蚀

性强等特点ꎬ目前已经在航空航天、航海、土木工程、

港口等结构或基础设施中得到了越来越广泛的应

用ꎮ 譬如我国国产大飞机 C919 大量采用复合材料ꎬ

用量达到 12%ꎻ在海港工程结构中ꎬFRP 筋有取代

传统受力钢筋的趋势ꎮ FRP 材料虽然具有良好的力

学和耐久性能ꎬ但是在高应力、紫外线等联合作用下

不可避免地会发生损伤ꎬ导致其承载能力下降ꎮ 譬如ꎬ

因环氧树脂胶粘贴工艺不达标ꎬ导致桥梁 CFRP 板

加固能力下降[1]

ꎻ因环境腐蚀ꎬFRP 筋与结构黏结

性能下降ꎬ导致结构承载能力下降[2]

ꎻ且 FRP 材料

自身在疲劳载荷作用下ꎬ其剩余刚度或使用寿命也

会逐渐降低[3]

ꎮ FRP 材料损伤或承载能力下降ꎬ会

影响结构的服役安全和使用寿命ꎬ因此有必要对

FRP 结构的力学性能进行监测[4]

ꎮ 蔚道祥等采用声

48 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

发射技术对 FRP 复合材料容器的损伤检测进行了研

究ꎬ实现了 FRP 材料的衰减测量和定位[5]

ꎮ 李伟等

运用三维参数法ꎬ分析研究了 FRP 材料声发射信号

的特征规律并从宏观上描述了 FRP 材料拉伸破坏规

律[6]

ꎮ Schulte 等采用电阻法对纤维增强复合材料

的拉伸损伤进行检测研究[7]

ꎮ 光纤的主要成分是二

氧化硅ꎬ热膨胀系数与纤维(特别是玻璃纤维)比较

相近ꎬ此外光纤本身体积小且抗电磁场干扰ꎬ被广泛

应用于航空工业和复合材料受力构件的监测中ꎮ 蒋

园园将光纤光栅传感器埋入热压罐成型的碳纤维材

料中ꎬ开展罐的损伤监测ꎬ解决了光纤引出保护的问

题[8]

ꎮ 吴慧峰基于光纤光栅传感技术开展飞机机翼

动态和静态两个工况下的形变测量ꎬ通过应变 ̄挠度

曲线关系重构机翼的形态[9]

ꎮ 李小伟基于光纤光栅

传感技术开展风机叶片检测ꎬ研究了光纤光栅传感

器在风机叶片中的布设位置与损伤信号的关系[10]

ꎮ

何建平等将光纤或光纤光栅植入 FRP 中研发 FRP 智

能筋ꎬ并将其应用到高速铁路路基沉降监测中ꎬ测试

效果证明光纤与 FRP 材料具有很好的协同变形且

FRP 能够有效保护传感光纤[11ꎬ12]

ꎮ Wang 等研究了

CFRP ̄FBG 复合材料加固钢结构的界面粘贴状态[13]

ꎬ

并对 FBG 植入纤维增强复合材料中的应变传递性能

进行了研究[14]

ꎮ

本文采用分布式光纤布里渊传感技术开展 CFRP

板变形监测ꎬ通过在 CFRP 悬臂板上布设分布式光

纤传感器开展 CFRP 损伤前后的变形研究ꎬ并探讨

分布式光纤传感器定点布设和连续布设测试的差异

性ꎮ 为验证变形监测方法的有效性ꎬ对分布式光纤

监测数据与布设在 FRP 板上电阻应变片测量值和

ABAQUS 有限元分析值进行了对比分析ꎮ

1 分布式光纤布里渊传感原理

基于布里渊散射谱分析ꎬ布里渊散射频移与温

度和应变呈线性关系ꎬ如式(1)所示:

ΔvB

=CεΔε +CTΔT (1)

式中:Cε ꎬCT 为应变和温度灵敏度系数ꎻΔεꎬΔT 为施

加在光纤上应变和温度增量[15ꎬ16]

ꎮ 对于普通光纤

而言ꎬCε

= 0? 05 MHz/ μεꎬCT

= 1? 00 MHz/ ℃ ꎮ

由式(1) 可以看出ꎬ光纤布里渊频移对温度和

应变同时敏感ꎮ 应变测试时ꎬ温度变化 1 ℃ 会导致

约 20 με 的不确定性ꎮ 实际工程服役对象在阴晴及

季节转换时会有较大温度差ꎬ因此ꎬ实际工程应变测

试需要温度补偿ꎮ 目前常用的补偿方法是在应变传

感器附近布设一根不受外力影响的温度光纤ꎬ基于

温度测试值对应变光纤进行一一补偿ꎬ如式( 2)

所示:

Δε =(ΔvB

-ψΔvB1 ) / Cε (2)

式中:ΔvB1(ΔvB1

=CTTΔT)为仅感知温度的布里渊频

移ꎬ即分布式光纤温度传感器感知的布里渊频移ꎻ

CTT为分布式光纤温度传感器的灵敏度系数ꎻψ = CT

/

CTT为分布式光纤应变传感器和分布式光纤温度传

感器的温度灵敏度系数比值ꎬ如果分布式光纤应变

传感器和分布式光纤温度传感器的封装材料一样ꎬ

则比值为 1ꎮ

2 碳纤维复合增强板( CFRP) 变形监测模

型试验

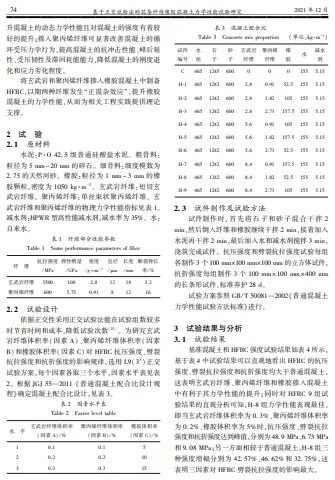

图 1 为基于分布式光纤传感技术的碳纤维复合

增强板(CFRP)变形监测试验模型ꎬ包括分布式光纤

布里渊光时域分析系统(BOTDA)、应变采集仪、碳

纤维复合增强板(CFRP)、光纤(OF)以及电阻应变

片ꎮ BOTDA 用于分布式光纤应变测试ꎬ应变采集仪

用于点式电阻应变片测试ꎮ

图 1 CFRP 板变形监测模型

Fig? 1 Photos of CFRP model for deformation measurement

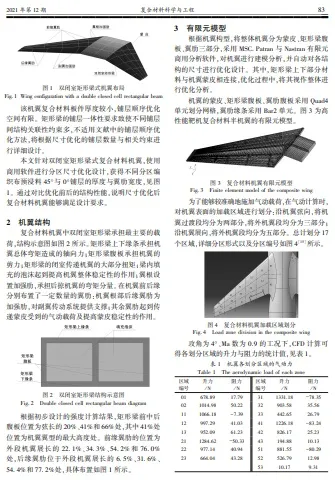

图 2 为分布式光纤和电阻应变片在 CFRP 板上

的布设位置示意图ꎮ CFRP 板尺寸为 1300 mm×50

mm×3? 2 mm(长×宽×高)ꎬ分布式光纤 OF1 为两端

定点固定在 CFRP 板表面ꎻ分布式光纤 OF2 通过 AB

胶连续粘贴在 CFRP 板表面ꎻOF1 和 OF2 平行相距

10 mmꎮ 为验证分布式光纤传感器应变测试的有效

性ꎬ在 CFRP 板表面离散布设 8 个电阻应变片ꎬ其中

Es1、Es2、Es3 和 Es4 分别距离 CFRP 板固定端 10 cm、

35 cm、60 cm 和 110 cmꎻEs1 和 Es5ꎬEs2 和 Es6ꎬEs3

和 Es7ꎬEs4 和 Es8 分别对称布设ꎬ具体布设位置如

图 2 所示ꎮ

2021 年第 12 期 49

???????????????????????????????????????????????

基于分布式光纤传感技术的 CFRP 板变形监测研究

图 2 传感器布设示意图

Fig? 2 Schematic diagram of sensor arrangement

CFRP 板单端固支ꎬ固支长度为 10 cmꎻ另一端

悬挂重物ꎮ 试验工况分为 CFRP 板无损工况和有损

工况ꎮ CFRP 板无损状态开展加载试验ꎬ每次试验

荷载步为 100 gꎬ最大荷载为 500 gꎮ 每加一级荷载ꎬ

BOTDA 采集 OF1 和 OF2 上的分布式光纤布里渊频

移ꎬ应变采集仪采集离散的电阻应变值ꎮ 损伤工况

为在 CFRP 板距端部位置 30 cm 开 2 条尺寸为 10

mm×3? 2 mm 的槽ꎬ然后进行步长为 100 g 的加载ꎬ

最大荷载为 700 gꎮ 本试验中 BOTDA 空间分辨率为

50 cmꎬ应变测量精度为± 20 μεꎬ采样点间距为 10

cmꎮ 试验在室内进行ꎬ环境温度基本保持恒定ꎬ应

变测试不考虑温度补偿ꎮ

3 试验结果分析

图 3 为 CFRP 板无损工况下基于 ABAQUS 软件

的有限元建模ꎬCFRP 板单端固支ꎬ另一端部受竖向

荷载ꎮ CFRP 板弹性模量为 55 GPaꎬ单元类型为

C3D8R 单元(八结点线性六面体单元ꎬ减缩积分)ꎬ

节点数为 10440 个ꎬ单元数为 7020 个ꎮ

(a)CFRP 板单端约束

(a)Single end restraint of CFRP plate

(b)CFRP 板网格划分

(b)Meshing of CFRP plate

图 3 CFRP 板有限元建模

Fig? 3 Finite element modeling of CFRP plate

图 4 和图 5 分别为 CFRP 板承受 500 g 荷载作用ꎬ

无损和有损工况下 CFRP 板有限元分析结果ꎮ 有损

工况下节点数为 11468 个ꎬ单元数为 7776 个ꎮ

图 4 无损工况下ꎬ500 g 作用下 CFRP 板变形云图

Fig? 4 Deformation nephogram of CFRP plate with

out damage under 500 g load

图 5 损伤工况下ꎬ500 g 作用下 CFRP 板变形云图

Fig? 5 Deformation nephogram of CFRP plate with

damage under 500 g load

图 6 为无损工况下ꎬ各级荷载作用下 CFRP 板

上 OF1 和 OF2 的布里渊频移 3D 分布ꎮ 因 OF1 两端

固定ꎬ为轴向拉伸ꎬ应变数据为 OF1 长度内的平均

应变ꎻOF2 为全粘贴在 CFRP 板上ꎬ所以 OF1 的布里

渊曲线要比 OF2 的布里渊曲线平坦ꎮ 图 7 为各级荷

载作用下ꎬCFRP 板上分布式光纤传感器测量应变

和理论应变(有限元分析应变) 的对比情况ꎮ 表 1

为 500 g 荷载作用下ꎬ分布式光纤传感器 OF1、OF2、

离散应变片测量应变与有限元分析得到的应变的对

比情况ꎮ 表中位置表示距离 CFRP 板固定端的距

离ꎬ应变片 1 表示 Es1、Es2、Es3 和 Es4ꎬ应变片 2 表

示 Es4、Es5、Es6 和 Es7ꎮ

(a)OF1

50 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

(b)OF2

图 6 各级荷载作用下 OF1 和 OF2 的布里渊频移

3D 示意图(CFRP 板无损工况)

Fig? 6 3D diagram of Brillouin frequency shift of OF1 and OF2

under different level loads (CFRP plate without damage)

(a)OF1

(b)OF2

图 7 各级荷载作用下分布式光纤传感器测量应变和

理论应变对比(CFRP 板无损工况)

Fig? 7 Strain comparison between OFs and FEM under

different level loads (CFRP plate without damage)

表 1 分布式光纤传感器 OF1、OF2、

应变片测量应变与有限元应变的对比

Table 1 Strain comparison of distributed optical

fiber sensorsꎬ ES and finite element strain

位置

/ cm

应变片 1

/ με

应变片 2

/ με

OF1

/ με

OF2

/ με

FEM

/ με

10 1163 1041 1182 1018 1031

35 767 759 796 709 750

60 549 567 708 516 562

110 233 223 220 122 93

可以看出ꎬ与 OF1 相比ꎬOF2 测量的应变值更接

近有限元分析得到的应变值ꎮ BOTDA 空间分辨率

为 50 cmꎬ因此理论上来说有限元分析得到的应变值

要大于分布式光纤传感器测量的应变值ꎮ 在 CFRP

板自由端附近ꎬ各级荷载作用下分布式光纤传感器

测量的应变值在有限元分析值附近上下波动ꎬ主要

原因是 CFRP 板自由端应变小ꎬ而 BOTDA 有一定的

测试误差ꎬ所以 OF2 误差的正负增量导致了应变测

量值的波动性ꎮ OF2 测量的应变要大于 OF1 和

FEM 分析应变ꎬ主要原因是 OF1 测量的是 CFRP 变

形时整体平均应变ꎮ 从图 6 的试验结果可以看出ꎬ

OF2 测量值反映了 CFRP 板连续变形ꎮ

图 8 为 CFRP 板损伤工况下ꎬ各级荷载作用下

CFRP 板上 OF1 和 OF2 的布里渊频移 3D 分布ꎬ依然

可以看出 OF1 的布里渊频移图要比 OF2 的布里渊频

移图平坦ꎮ 图 9 为各级荷载作用下ꎬ带损伤的 CFRP

板上分布式光纤传感器测量应变和理论应变(有限元

分析应变)的对比情况ꎮ 可以明显看出ꎬ在 CFRP 板

损伤位置ꎬ有限元分析得到的应变曲线和 OF2 测量曲

线均有一个突变点ꎮOF1 测量的应变曲线没有识别出

损伤ꎬ主要原因是 OF1 测试的是 CFRP 板的整体平均

应变ꎬ而 CFRP 自由端附近虽然有损伤ꎬ但是本身因

损伤导致的应变比较小ꎮ 同样可以看出ꎬOF2 测量的

应变要比 OF1 测量的应变更为接近 FEM 分析应变ꎮ

(a)OF1

(b)OF2

图 8 各级荷载作用下ꎬOF1 和 OF2 的布里渊频移

3D 示意图(CFRP 板损伤工况)

Fig? 8 3D diagram of Brillouin frequency shift of OF1 and OF2

under different level loads (CFRP plate with damage)

2021 年第 12 期 51

???????????????????????????????????????????????

基于分布式光纤传感技术的 CFRP 板变形监测研究

(a)OF1

(b)OF2

图 9 各级荷载作用下ꎬ分布式光纤传感器测量应变和

理论应变对比(CFRP 板损伤工况)

Fig? 9 Strain comparison between OFs and FEM under

different level loads (CFRP plate with damage)

4 结 论

本文在 CFRP 板表面连续和定点布设分布式光

纤传感器ꎬ基于布里渊光纤传感技术开展 CFRP 板

变形监测研究ꎬ并通过有限元分析和离散应变片对

比研究分布式光纤传感器测试的有效性ꎮ 所得主要

结论如下:

(1)分布式光纤传感器可以获取 CFRP 板表面

连续的应变或变形分布ꎬ测量的连续应变与局部应

变片测量值、ABAQUS 有限元分析值基本一致ꎮ

(2)分布式光纤传感器布设在 CFRP 板表面时ꎬ

连续布设比定点布设更能反映 CFRP 板的真实变

形ꎬ且在此监测试验中ꎬ分布式光纤传感器连续布设

能够识别 CFRP 板损伤ꎬ定点布设工况中ꎬ由于两个

定点距离较长ꎬ损伤信息被其他位置信息给平均化

处理掉了ꎬ因此不能有效识别损伤ꎮ

参考文献

[1] 王磊ꎬ 李威ꎬ 陈爽ꎬ 等. 海水浸泡对 FRP 筋 ̄珊瑚混凝土粘结性

能的影响[J]. 复合材料学报ꎬ 2018ꎬ 35(12): 3458 ̄3465.

[2] 杜云兴ꎬ 侯春旭ꎬ 周芬. 不均匀胶层对 CFRP 板加固梁的界面应

力影响[J]. 湖南大学学报(自然科学版)ꎬ 2017ꎬ 44(3): 61 ̄67.

[3] 宗俊达ꎬ 姚卫星. FRP 复合材料剩余刚度退化复合模型[ J]. 复

合材料学报ꎬ 2016ꎬ 33(2): 280 ̄286.

[4] 李水扬ꎬ 李峰ꎬ 马青那ꎬ 等. 动态监测技术在 FRP 试验中的应用

[J]. 现代交通技术ꎬ 2015ꎬ 12(5): 35 ̄39.

[5] 蔚道祥ꎬ 杨宇清ꎬ 鲁洪亮ꎬ 等. 声发射检测技术在 FRP 复合材料

容器检测中的应用研究[J]. 广州化工ꎬ 2019ꎬ 47(14): 152 ̄153.

[6] 李伟ꎬ 王宇ꎬ 吴超群ꎬ 等. 基于声发射检测技术的 FRP 复合材料

损伤试验研究[J].化工机械ꎬ 2011ꎬ 38(6): 692 ̄696.

[7] SCHULTE Kꎬ BARON C. Load and failure analysis of CFRP lami ̄

nates by means of electrical resistivity measurements[J]. Composites

Science and Technologyꎬ 1989ꎬ 36(1): 63 ̄65.

[8] 蒋园园. 光纤光栅传感器应用于复合材料损伤监测的研究[D].

武汉: 武汉理工大学ꎬ 2012.

[9] 吴慧峰. 基于光纤光栅传感技术的机翼形变测量方法研究与分

析[J]. 桂林航天工业学院学报ꎬ 2017ꎬ 4: 359 ̄364.

[10] 李小伟. 基于光纤光栅传感技术的风机叶片检测研究[D]. 南

京: 南京航空航天大学ꎬ 2013.

[11] XU Jꎬ HE J Pꎬ ZHANG L. Collapse prediction of karst sinkhole via

distributed Brillouin optical of sensor[J]. Measurementꎬ 2017ꎬ 100:

68 ̄71.

[12] CHEN H Jꎬ HE J Pꎬ XUE Yꎬ et al. Experimental study on sinkhole

collapse monitoring based on distributed Brillouin optical fiber

sensor[J]. Optikꎬ 2020ꎬ 216(164825): 1 ̄10.

[13] WANG H Pꎬ NI Y Qꎬ DAI J Gꎬ et al. Interfacial debonding detec ̄

tion of strengthened steel structures by using smart CFRP ̄FBG com ̄

posites[ J]. Smart Materials and Structuresꎬ 2019ꎬ 28( 115001):

1 ̄13.

[14] WANG H Pꎬ DAI J G. Strain transfer analysis of fiber Bragg grating

sensor assembled composite structures subjected to thermal loading

[J]. Composites Part B: Engineeringꎬ 2019ꎬ 162: 303 ̄313.

[15] CULVERHOUSE Dꎬ FARAHI F. Potential of stimulated Brillouin

scattering as sensing mechanism for distributed temperature sensors

[J]. Electronics Lettersꎬ 1989ꎬ 25: 913 ̄915.

[ 16] HORIGUCHI Tꎬ KURASHIMA Tꎬ TATEDA M. A technique to

measure distributed strain in optical fibers [ J]. IEEE Photonics

Technology Lettersꎬ 1990ꎬ 2(5): 352 ̄354.

52 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

DOI:10? 19936 / j? cnki? 2096 ̄8000? 20211228? 008

磁致取向碳纳米管增强玻璃纤维 / 环氧复合材料的层间性能研究

黄东辉1ꎬ2

ꎬ 曾少华2∗

(1? 安徽森泰木塑集团股份有限公司ꎬ 广德 242200ꎻ 2? 安徽大学 化学化工学院ꎬ 合肥 230601)

摘要: 为提升玻璃纤维/ 环氧复合材料(GFRE)的层间性能ꎬ本文采用共价键合的方式将四氧化三铁(Fe3O4 )纳米磁球负

载于多壁碳纳米管(MWCNTs)表面得到 Fe3O4@MWCNTs 纳米粒子ꎬ再将其通过三辊研磨、超声分散于环氧树脂中ꎬ并利用弱

磁场诱导制备含取向 MWCNTs 的玻璃纤维/ 环氧复合材料ꎮ 结果表明:弱磁场作用下 MWCNTs 沿树脂流动方向取向分布ꎬ并

且 MWCNTs 和 Fe3O4在树脂中具有协同助分散的作用ꎬ取向且分散均匀的 MWCNTs 能够增强与增韧复合材料层间区域ꎬ实现

复合材料力学性能和热性能的提升ꎻ相比于纯 GFREꎬ含取向 MWCNTs 复合材料的层间剪切强度和断裂功分别提升约 31%和

117%ꎬ拉伸、弯曲性能及储能模量都有明显提升ꎬ且玻璃化转变温度提高了约 7 ℃ ꎮ

关键词: 纤维增强复合材料ꎻ 环氧树脂ꎻ 碳纳米管ꎻ 取向ꎻ 层间剪切强度

中图分类号: TB332 文献标识码: A 文章编号: 2096-8000(2021)12-0053-07

Interlaminar properties of magnetically oriented carbon nanotubes ̄reinforced glass fiber /epoxy composites

HUANG Dong ̄hui

1ꎬ2

ꎬ ZENG Shao ̄hua

2∗

(1? Anhui Sentai Wood Plastic Group Co.ꎬ Ltd.ꎬ Guangde 242200ꎬ Chinaꎻ

2? College of Chemistry & Chemical Engineeringꎬ Anhui Universityꎬ Hefei 230601ꎬ China)

Abstract:To improve the interlaminar properties of glass fiber reinforced epoxy composites (GFRE)ꎬ ferroferric

oxide@multi ̄walled carbon nanotubes nanoparticles (Fe3O4@MWCNTs) were prepared by depositing Fe3O4

on the

surface of MWCNTs based on the covalent bondingꎬ and then such nanoparticles were dispersed in epoxy resin by

three ̄roll grinding and ultrasound methods. The glass fiber/epoxy composites containing oriented MWCNTs were fab ̄

ricated under a weak magnetic field. The results showed that MWCNTs were distributed along the flow direction of

resins under a weak magnetic fieldꎬ and MWCNTs and Fe3O4

could promote mutual co ̄dispersion in resins. MWC ̄

NTs with uniform orientation and dispersion could strengthen and toughen the interlaminar region of compositesꎬ and

the improved mechanical and thermal properties of composites could be realized. Compared with pure GFREꎬ the in ̄

terlaminar shear strength and work of fracture of composites containing oriented MWCNTs were increased by about

31% and 117%ꎬ respectively. The tensile and flexural properties and storage moduli were significantly improvedꎬ

and the glass transition temperature was increased by about 7 ℃ .

Key words:fiber ̄reinforced compositesꎻ epoxy resinꎻ carbon nanotubesꎻ orientationꎻ interlaminar shear strength

收稿日期: 2021 ̄04 ̄13

基金项目: 安徽省高等学校自然科学研究重点项目 (KJ2020A0015)ꎻ 安徽大学博士科研启动经费 (S020318008 / 003)

作者简介: 黄东辉 (1972 ̄)ꎬ 男ꎬ 学士ꎬ 高级工程师ꎬ 主要从事高分子复合材料成型工艺方面的研究ꎮ

通讯作者: 曾少华 (1990 ̄)ꎬ 男ꎬ 博士ꎬ 讲师ꎬ 主要从事纤维增强复合材料表界面改性及功能化应用方面的研究ꎬ shzeng@ahu? edu? cnꎮ

1 前 言

玻璃纤维增强聚合物基复合材料(GFRP)具有

比强度和比模量高、可设计性强、耐腐蚀性好等优

点ꎬ已被广泛应用于民用基础设施领域[1ꎬ2]

ꎮ 但在

需要承受较大弯曲应力或高剪切力的应用场合ꎬ

GFRP 往往出现层间破坏现象ꎬ导致结构寿命缩短

或失效ꎮ 为了抑制分层破坏ꎬ常采用三维编织、Z ̄

pinning 技术、缝合等方法提高 GFRP 层间性能[3ꎬ4]

ꎮ

然而这些技术大多存在工艺局限性、性能提升有限

及成本较高等问题ꎮ 采用蒙脱土、碳纳米管、石墨烯

等纳米材料填充树脂基体是现阶段使用最广泛的

GFRP 层间性能强化方式[5 ̄7]

ꎮ 其中ꎬ碳纳米管以其

优良的力学、电学、热学等特性成为复合材料的理想

增强填料之一ꎬ将其引入 GFRP 体系符合高性能复

2021 年第 12 期 53

???????????????????????????????????????????????

磁致取向碳纳米管增强玻璃纤维/ 环氧复合材料的层间性能研究

合材料低成本制造的发展方向[8]

ꎮ

碳纳米管具有高长径比和高比表面积ꎬ其轴向

性能远远优于径向性能ꎮ 通过调控碳纳米管在 GFRP

厚度方向的取向状态ꎬ可有效提升 GFRP 的层间性

能ꎮ 目前ꎬ在 GFRP 中置入取向碳纳米管的方法有

两种:一是以玻纤为模版ꎬ通过化学气相沉积法在玻

纤表面生长定向碳纳米管ꎬ再与纯树脂通过手糊、树

脂传递模塑等成型工艺制备复合材料[9]

ꎻ二是将碳

纳米管分散于树脂中ꎬ利用物理场(流场、电场、磁场

等)使碳纳米管在树脂中取向排列[10]

ꎮ 前者工艺需

要在玻纤表面负载催化剂ꎬ后处理难以除净ꎬ且生长

碳纳米管一般需要高温(>500 ℃ )ꎬ这种高温反应环

境容易损伤玻纤力学性能[11]

ꎮ 利用电、磁场诱导碳

纳米管的有序排列逐渐受到青睐ꎮ 如董怀斌等[12] 利

用高频电场诱导法制备了多壁碳纳米管(MWCNTs)

定向排列的碳纤维/ 环氧复合材料ꎬMWCNTs 的定向

排列有效提升了复合材料的力学性能ꎮ 为了提高碳

纳米管磁性ꎬ研究者多采用磁性粒子改性碳纳米管ꎬ

再利用磁场诱导碳纳米管在树脂中取向或定向[13ꎬ14]

ꎮ

但这些研究主要集中于碳纳米管改性聚合物复合材

料ꎬ很少涉及碳纳米管有序增强 GFRP 层间性能ꎮ

针对 GFRP 层间性能不足的问题ꎬ本文先将 Fe3O4

纳米磁球负载于多壁碳纳米管(MWCNTs)表面得到

Fe3O4@MWCNTsꎬ然后将其通过三辊研磨、超声分散

于环氧树脂中ꎻ将混合树脂通过手糊涂覆于玻纤织

物中ꎬ再先后置于真空袋和弱磁场中得到含取向

MWCNTs 的玻纤/ 环氧复合材料ꎮ 重点研究弱磁场诱

导取向 MWCNTs 对 GFRP 微观结构及层间性能的影

响ꎬ探讨了取向 MWCNTs 对复合材料层间增强机理ꎮ

2 实验部分

2? 1 主要原料

羧基化 MWCNTs(工业级ꎬ直径为 20 nm~40 nmꎬ

长度约为 30 μm)为中国科学院成都有机化学有限

公司生产ꎻE ̄玻纤织物(纤维直径约为 17 μmꎬ面密

度为 1200 g / m

2

)、环氧树脂(LY1564ꎬ25 ℃下黏度为

1200 mPa?s~1400 mPa?s)及其固化剂(A3486ꎬ25 ℃下

黏度为 10 mPa?s~20 mPa?s)均由连云港中复连众

复合材料集团有限公司提供ꎻFe3O4纳米磁球(直径

约为 50 nm) 和钕铁硼磁铁(磁感应强度约为 3500

Gs)分别购于杭州恒纳新材料有限公司和无锡申磁

磁业有限公司ꎻγ ̄氨丙基三乙氧基硅烷(KH550)、

NꎬN ̄二异丙基碳二亚胺( DIC)、 1 ̄羟基苯丙三唑

(HOBT)、二甲基亚砜(DMSO)、无水乙醇等均购自

南京化学试剂股份有限公司ꎮ

2? 2 样品制备

2? 2? 1 Fe3O4@MWCNTs 的制备

将 DIC、HOBT、KH550和 MWCNTs(质量比为 0? 01 ∶

0? 01 ∶ 0? 01 ∶1)分别加入溶剂 DMSO 中ꎬ超声 30 min 后

机械搅拌 6 hꎬ将混合液静置、离心ꎬ倒掉上层清液并用

无水乙醇清洗 2 次~3 次ꎬ得到 KH550 改性 MWCNTsꎻ

然后ꎬ将其与 Fe3O4(质量比为 Fe3O4

∶MWCNTs = 1∶4)

分散于无水乙醇中ꎬ超声 10 min 后向混合液中滴加

去离子水(质量比为去离子水 ∶无水乙醇= 4 ∶96)ꎬ保

持搅拌 10 min 后离心去除上层清液ꎬ100 ℃ 真空干

燥后得到 Fe3O4@MWCNTs(制备过程见图 1)ꎮ

图 1 Fe3O4@MWCNTs 制备工艺示意图

Fig? 1 Schematic diagram of preparation process

of Fe3O4@MWCNTs

2? 2? 2 取向 MWCNTs 复合材料的制备

裁剪玻纤织物(尺寸为 250 mm×150 mm)ꎬ并分别

计算称量 LY1564 和 A3486 待用( LY1564 ∶A3486 =

100 ∶ 34)ꎮ 按照 LY1564 和 A3486 总质量计ꎬ称取

0? 5wt%的 Fe3O4@MWCNTs 加入 LY1564 中ꎬ经机械

搅拌 2 h、三辊研磨 2 min~4 min 后加入 A3486ꎬ搅拌

均匀后真空脱气泡得到 MWCNTs 混合液ꎻ然后ꎬ将

其通过手糊ꎬ均匀地涂覆于玻璃纤维织物中ꎬ再置于

真空袋中抽真空除空气ꎬ同时将钕磁铁放置在真空

袋上下表面ꎻ最后经室温固化 24 h、70 ℃下后固化 6

h 得到取向 MWCNTs 增强玻纤/ 环氧复合材料(记为

Fe@M ̄m ̄GFRE)ꎮ 类似上述步骤ꎬ分别将 0? 5wt%的

54 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

MWCNTs、Fe3O4@MWCNTs 置于磁场及无磁场环境

中制备复合材料ꎬ分别记为 M ̄m ̄GFRE 和 Fe@M ̄n ̄

GFREꎮ此外ꎬ制备纯 GFRE 作为空白试样ꎮ

2? 3 测试与表征

利用傅里叶红外光谱仪(FTIRꎻVertex 80vꎬBrukerꎬ

德国)分析纳米粒子的化学结构ꎮ 分别通过场发射

扫描电子显微镜( SEMꎻInspect F50ꎬFEIꎬ美国)和 X

射线能谱仪(EDXꎻOctane SuperꎬEDAXꎬ美国) 表征

Fe3O4@MWCNTs 粉末的表面形貌及元素分布ꎮ 将复

合材料分层后ꎬ选择树脂基体富集区域采用超薄切

片机(EM UC7ꎬLeicaꎬ德国)进行切片ꎬ并利用透射电

子显微镜(TEMꎻJEM ̄1400ꎬJEOLꎬ日本)观察复合材

料中 MWCNTs 分散及定向状态ꎮ

复合材料的力学性能皆利用电子万能试验机

(CMT ̄5105ꎬSANSꎬ中国) 测试ꎬ拉伸性能测试参照

GB/ T 1447—2005ꎬ试样尺寸为 2 mm×25 mm×150 mmꎬ

加载速度为 2? 0 mm / minꎻ弯曲性能测试参照 GB / T

1449—2005ꎬ试样尺寸为 2 mm×15 mm×40 mmꎬ跨距

为 32 mmꎬ加载速度为 2? 0 mm / minꎻ层间剪切性能

测试参照 ISO 14130—1997ꎬ试样尺寸为 4 mm × 20

mm× 40 mmꎬ跨距为 16 mmꎬ加载速度为 1? 0 mm /

minꎮ 采用表面电阻测试仪(SL ̄030Bꎬ无锡欣律图防

静电设备有限公司ꎬ中国)测试表面电阻ꎮ 复合材料

的动态力学热性能采用动态力学热分析仪(Q800ꎬ

TAꎬ美国)测试ꎬ试样尺寸为 2 mm×10 mm×60 mmꎬ

采用三点弯曲模式在空气氛围下以 5 ℃ / min 的速

率从室温升至 180 ℃ ꎬ频率为 1 Hzꎮ

3 结果与讨论

3? 1 Fe3O4@MWCNTs 的结构与形貌

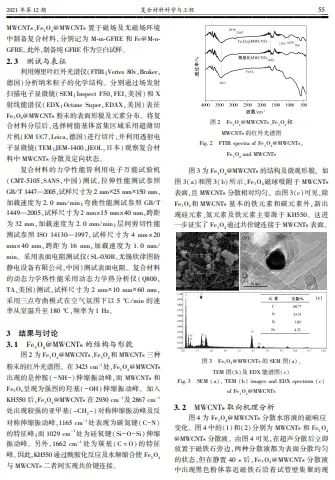

图 2 为 Fe3O4@MWCNTs、Fe3O4和 MWCNTs 三种

粉末的红外光谱图ꎮ 在 3423 cm

-1处ꎬFe3O4@MWCNTs

出现的是仲胺( -NH-)伸缩振动峰ꎬ而 MWCNTs 和

Fe3O4呈现为强烈的羟基( -OH)伸缩振动峰ꎮ 加入

KH550 后ꎬFe3O4@MWCNTs 在 2930 cm

-1及 2867 cm

-1

处出现较强的亚甲基(-CH2

-)对称伸缩振动峰及反

对称伸缩振动峰ꎬ1165 cm

-1处表现为碳氮键(C-N)

的特征峰ꎻ而 1029 cm

-1处为硅氧键( Si-O-Si)伸缩

振动峰ꎮ 另外ꎬ1662 cm

-1 处为羰基(C = O) 的特征

峰ꎮ因此ꎬKH550 通过酰胺化反应及水解缩合使 Fe3O4

与 MWCNTs 二者间实现共价键连接ꎮ

图 2 Fe3O4@MWCNTs、Fe3O4和

MWCNTs 的红外光谱图

Fig? 2 FTIR spectra of Fe3O4@MWCNTsꎬ

Fe3O4

and MWCNTs

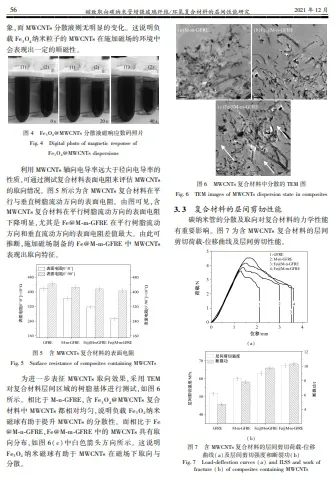

图 3 为 Fe3O4@MWCNTs 的结构及微观形貌ꎮ 如

图 3(a)和图 3(b)所示ꎬFe3O4磁球吸附于 MWCNTs

表面ꎬ且 MWCNTs 分散相对均匀ꎮ 由图 3(c)可见ꎬ除

Fe3O4和 MWCNTs 基本的铁元素和碳元素外ꎬ新出

现硅元素、氮元素及铁元素主要源于 KH550ꎮ 这进

一步证实了 Fe3O4通过共价键连接于 MWCNTs 表面ꎮ

图 3 Fe3O4@MWCNTs 的 SEM 图(a)、

TEM 图(b)及 EDX 能谱图(c)

Fig? 3 SEM (a)ꎬ TEM (b) images and EDX spectrum (c)

of Fe3O4@MWCNTs

3? 2 MWCNTs 取向机理分析

图 4 为 Fe3O4@MWCNTs 分散水溶液的磁响应

变化ꎮ 图 4 中的(1)和(2)分别为 MWCNTs 和 Fe3O4

@MWCNTs 分散液ꎮ 由图 4 可见ꎬ在超声分散后立即

放置于磁铁石旁边ꎬ两种分散液都为表面分散均匀

的状态ꎬ但在静置 40 s 后ꎬFe3O4@MWCNTs 分散液

中出现黑色粉体靠近磁铁石沿着试管壁集聚的现

2021 年第 12 期 55

???????????????????????????????????????????????

磁致取向碳纳米管增强玻璃纤维/ 环氧复合材料的层间性能研究

象ꎬ而 MWCNTs 分散液则无明显的变化ꎮ 这说明负

载 Fe3O4纳米粒子的 MWCNTs 在施加磁场的环境中

会表现出一定的顺磁性ꎮ

图 4 Fe3O4@MWCNTs 分散液磁响应数码照片

Fig? 4 Digital photo of magnetic response of

Fe3O4@MWCNTs dispersions

利用 MWCNTs 轴向电导率远大于径向电导率的

性质ꎬ可通过测试复合材料表面电阻来评估 MWCNTs

的取向情况ꎮ 图 5 所示为含 MWCNTs 复合材料在平

行与垂直树脂流动方向的表面电阻ꎮ 由图可见ꎬ含

MWCNTs 复合材料在平行树脂流动方向的表面电阻

下降明显ꎬ尤其是 Fe@M ̄m ̄GFRE 在平行树脂流动

方向和垂直流动方向的表面电阻差值最大ꎮ 由此可

推断ꎬ施加磁场制备的 Fe@M ̄m ̄GFRE 中 MWCNTs

表现出取向特征ꎮ

图 5 含 MWCNTs 复合材料的表面电阻

Fig? 5 Surface resistance of composites containing MWCNTs

为进一步表征 MWCNTs 取向效果ꎬ采用 TEM

对复合材料层间区域的树脂基体进行测试ꎬ如图 6

所示ꎮ 相比于 M ̄n ̄GFREꎬ含 Fe3O4@MWCNTs 复合

材料中 MWCNTs 都相对均匀ꎬ说明负载 Fe3O4纳米

磁球有助于提升 MWCNTs 的分散性ꎮ 而相比于 Fe

@M ̄n ̄GFREꎬFe@M ̄m ̄GFRE 中的 MWCNTs 具有取

向分布ꎬ如图 6( c) 中白色箭头方向所示ꎮ 这说明

Fe3O4 纳米磁球有助于 MWCNTs 在磁场下取向与

分散ꎮ

图 6 MWCNTs 复合材料中分散的 TEM 图

Fig? 6 TEM images of MWCNTs dispersion state in composites

3? 3 复合材料的层间剪切性能

碳纳米管的分散及取向对复合材料的力学性能

有重要影响ꎮ 图 7 为含 MWCNTs 复合材料的层间

剪切荷载 ̄位移曲线及层间剪切性能ꎮ

(a)

(b)

图 7 含 MWCNTs 复合材料的层间剪切荷载 ̄位移

曲线(a)及层间剪切强度和断裂功(b)

Fig? 7 Load ̄deflection curves (a) and ILSS and work of

fracture (b) of composites containing MWCNTs

56 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

由图 7( a) 可知ꎬ相比于纯 GFREꎬ含 MWCNTs

复合材料的层间剪切荷载明显增加ꎬ且到达峰值后

仍保持缓慢降低的趋势ꎬ说明 MWCNTs 能够提升复

合材料的层间性能ꎻ进一步地ꎬFe@M ̄n ̄GFRE 和 Fe

@M ̄m ̄GFRE 的层间剪切荷载峰值及位移都高于 M ̄

m ̄GFREꎬ说明 MWCNTs 和 Fe3O4对复合材料层间剪

切性能具有协同增强的效果ꎮ

断裂功(即荷载 ̄位移曲线面积)可被用于衡量

复合材料的层间断裂韧性[15]

ꎮ 如图 7( b) 所示ꎬFe

@M ̄m ̄GFRE 的层间剪切强度和断裂功都拥有最大

值ꎬ且其层间剪切强度和断裂功较之纯 GFRE 分别

提升 30? 7%和 117? 1%ꎬ断裂功提升最明显ꎮ 取向

MWCNTs 不仅改善了复合材料的层间黏合强度ꎬ还

提升了复合材料的层间断裂韧性ꎮ

取向 MWCNTs 对复合材料层间断裂韧性的影

响还可进一步通过层间断裂形貌证实ꎬ如图 8 所示ꎮ

纯 GFRE 的层间剪切断面平整ꎬ且纤维表面光滑ꎬ含

有极少量的树脂ꎬ见图 8( a)ꎬ这表现出脆性断裂现

象ꎮ 由图 8(b) ~图 8(d)可见ꎬMWCNTs 复合材料层

间剪切断面相对粗糙ꎬ且纤维表面黏附更多的树脂

碎片ꎬ尤其是 Fe @ M ̄m ̄GFRE 表面更加明显ꎮ 但

M ̄m ̄GFRE表面含有少量 MWCNTs 团聚体ꎮ 结合图

3 和图 8 可说明ꎬFe3O4纳米球不仅赋予了 MWCNTs

一定的顺磁性ꎬ使之顺利取向ꎬ还有助于提高 MWCNTs

在树脂中的分散性ꎬ两者协同作用下实现了复合材

料层间黏合性及断裂韧性的提升ꎮ

图 8 含 MWCNTs 复合材料的层间剪切断面

Fig? 8 Interlaminar shear fracture surfaces of

composites containing MWCNTs

3? 4 复合材料的拉伸和弯曲性能

图 9 为含 MWCNTs 复合材料的拉伸和弯曲性能ꎮ

由图9(a)和图9(b)可知ꎬ添加 MWCNTs 使复合材料的

拉伸和弯曲性能均有所提高ꎬ尤其是 Fe@M ̄m ̄GFRE

的力学性能提升最明显ꎮ 相比于纯 GFREꎬFe@M ̄m ̄

GFRE 的拉伸强度和模量分别提高了 26? 7%和 22? 1%ꎬ

弯曲强度和模量分别提高了 25? 0%和 23? 8%ꎮ 这说

明取向 MWCNTs 在复合材料受力过程中有助于传

递和消散应力ꎬ进而提升复合材料的力学性能ꎮ

(a)

(b)

图 9 含 MWCNTs 复合材料的拉伸(a)及弯曲(b)性能

Fig? 9 Tensile (a) and flexural (b) properties of

composites containing MWCNTs

3? 5 复合材料的动态力学热性能

含 MWCNTs 复合材料的储能模量和损耗因子

随温度的变化分别如图 10(a)和图 10(b)所示ꎮ 表

1 列出了含 MWCNTs 的复合材料在 30 ℃ 和 180 ℃

时的储能模量(分别记为 E30

′和 E180

′)、玻璃化转变

温度(Tg)和损耗因子峰值(Tanδmax)ꎮ

(a)

2021 年第 12 期 57

???????????????????????????????????????????????

磁致取向碳纳米管增强玻璃纤维/ 环氧复合材料的层间性能研究

(b)

图 10 含 MWCNTs 复合材料的储能模量(a)及

损耗因子(b)随温度的变化曲线

Fig? 10 Storage modulus (a) and loss factor (b) via

temperature curves of composites containing MWCNTs

表 1 含 MWCNTs 复合材料的储能模量、

玻璃化转变温度和损耗因子峰值

Table 1 Storage modulusꎬ Tg

and Tanδmax

of composites containing MWCNTs

试样编号 E30

′/ GPa E180

′/ GPa Tg

/ ℃ Tanδmax

GFRE 27.6 5.46 82.7 0.23

M ̄m ̄GFRE 28.0 6.92 84.2 0.19

Fe@M ̄n ̄GFRE 28.9 7.49 87.2 0.17

Fe@M ̄m ̄GFRE 29.9 8.08 89.3 0.16

由图 10(a)和表 1 可知ꎬ含 MWCNTs 复合材料在

玻璃态和橡胶态的储能模量都高于纯 GFREꎬ且其

在玻璃化转变区域储能模量下降趋势较之纯 GFRE

更加缓慢ꎻ取向 MWCNTs 增强复合材料的储能模量

提升最明显ꎮ 相比于纯 GFREꎬFe@ M ̄m ̄GFRE 的

E30

′和 E180

′分别提升了 8? 3%和 48? 0%ꎮ 分析可知ꎬ取

向 MWCNTs 提高了纤维与树脂之间的界面交互作

用ꎬ降低了纤维附近环氧分子链的流动性ꎬ导致复合

材料的储能模量明显提高ꎻ并且取向 MWCNTs 在复

合材料橡胶态中由取向转向无规状态需要更多的能

量ꎬ使其复合材料具有高温保持性ꎮ

由于 MWCNTs 在复合材料中占据着一定的自由

体积ꎬ限制了环氧分子链的运动ꎬ这就需要更高的温

度才能提供更充足的空间ꎬ使环氧分子链解冻ꎬ进而

导致复合材料的 Tg升高ꎮ 由表 1 可知ꎬFe@M ̄m ̄GFRE

的 Tg值最大ꎬ且较之纯 GFRE 提高了约 7 ℃ ꎮ 这说

明取向 MWCNTs 更有利于提升复合材料的耐热性ꎮ

此外ꎬ相比于纯 GFREꎬFe@M ̄m ̄GFRE 的 Tanδmax值

降低最明显ꎬ且较之纯 GFRE 下降了 30? 4%ꎮ 这进

一步证实取向 MWCNTs 提升了复合材料的层间黏

合性ꎮ

4 结 论

本文将 Fe3O4负载多壁碳纳米管(Fe3O4@MWC ̄

NTs)采用三辊研磨和超声分散于环氧树脂中ꎬ通过

手糊及抽真空工艺将混合树脂与玻璃纤维织物复

合ꎬ再在弱磁场诱导下制备含取向 MWCNTs 的复合

材料ꎻ重点研究取向 MWCNTs 对复合材料层间性能

的影响ꎮ 结果表明:

(1)Fe3O4纳米磁球有助于提高 MWCNTs 的顺

磁性及其在树脂中的分散性ꎬ实现 MWCNTs 沿树脂

流动方向取向分布ꎮ

(2)取向且分散均匀的 MWCNTs 有助于增强与

增韧复合材料层间树脂富集区域ꎻ相比于纯 GFREꎬ

含取向 MWCNTs 复合材料的层间剪切强度和断裂

功分别提升约 31%和 117%ꎮ

(3)取向 MWCNTs 能够实现复合材料力学性能

和热性能的提升ꎻ相比于纯 GFREꎬ含取向 MWCNTs

复合材料的拉伸强度和模量分别提高了约 27%和

22%ꎬ弯曲强度和模量分别提高了约 25%和 24%ꎻ储

能模量在玻璃态和橡胶态都有所提升ꎬ而且玻璃化

转变温度提高了约 7 ℃ ꎮ

参考文献

[1] 刘伟庆ꎬ 方海ꎬ 方园. 纤维增强复合材料及其结构研究进展[J].

建筑结构学报ꎬ 2019ꎬ 40(4): 1 ̄16.

[2] LIU Tꎬ FENG Pꎬ WU Yꎬ et al. Developing an innovative curved ̄

pultruded large ̄scale GFRP arch beam[ J]. Composite Structuresꎬ

2021ꎬ 256: 113111.

[ 3] COPPOLA A Mꎬ THAKRE P Rꎬ SOTTOS N Rꎬ et al. Tensile prop ̄

erties and damage evolution in vascular 3D woven glass/ epoxy com ̄

posites[J]. Composites Part A: Applied Science and Manufacturingꎬ

2014ꎬ 59: 9 ̄17.

[4] 孟令民ꎬ 周克印ꎬ 王崇高ꎬ 等. Z ̄pin 增强复合材料层合板缺陷

的红外检测技术研究[J]. 玻璃钢/ 复合材料ꎬ 2019(5): 31 ̄37.

[5] SHARMA Bꎬ CHHIBBER Rꎬ MEHTA R. Curing studies and me ̄

chanical properties of glass fiber reinforced composites based on si ̄

lanized clay minerals[J]. Applied Clay Scienceꎬ 2017ꎬ 138: 89 ̄99.

[6] 郑益飞ꎬ 申明霞ꎬ 段鹏鹏ꎬ 等. 含 MWCNTs 玻璃纤维增强复合材

料的力学和界面性能的研究[J]. 玻璃钢/ 复合材料ꎬ 2019(12):

83 ̄88.

[7] VALOROSI Fꎬ DE MEO Eꎬ BLANCO ̄VARELA Tꎬ et al. Graphene

and related materials in hierarchical fiber composites: Production

techniques and key industrial benefits [ J]. Composites Science &

Technologyꎬ 2020ꎬ 185: 107848.

[8] 汪庆卫ꎬ 吴欣ꎬ 王宏志ꎬ 等. 表面修饰碳纳米管对玻璃纤维及复

合材料的性能影响[J]. 功能材料ꎬ 2015ꎬ 46(23): 23047 ̄23050.

[9] BODDU V Mꎬ BRENNER M Wꎬ PATEL J Sꎬ et al. Energy dissipa ̄

tion and high ̄strain rate dynamic response of E ̄glass fiber composites

with anchored carbon nanotubes[J]. Composites Part B: Engineeringꎬ

58 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

2016ꎬ 88: 44 ̄54.

[10] 刘方彪ꎬ 王丹勇ꎬ 徐井利ꎬ 等. 取向碳纳米管/ 玻璃纤维增强树

脂基单向层合板的制备及其力学性能[ J]. 材料科学与工程学

报ꎬ 2015ꎬ 33(2): 163 ̄167.

[11] RAHAMAN Aꎬ KAR K K. Carbon nanomaterials grown on E ̄glass

fibers and their application in composite[J]. Composites Science &

Technologyꎬ 2014ꎬ 101: 1 ̄10.

[12] 董怀斌ꎬ 李长青ꎬ 任攀ꎬ 等. 碳纳米管定向排列增强碳纤维/ 环

氧树脂复合材料制备及力学性能[J]. 玻璃钢/ 复合材料ꎬ 2017

(7): 23 ̄29.

[13] 周还潮ꎬ 马传国ꎬ 张晶晶. 弱磁场对 EP / MWCNTs ̄Fe3 O4 复合

材料结构与性能的影响[ J]. 工程塑料应用ꎬ 2015ꎬ 43( 10):

7 ̄12.

[14] 陈伟ꎬ 郑亚萍. Fe3O4

̄MWCNTs 在环氧树脂中的定向排列[ J].

复合材料学报ꎬ 2013ꎬ 30(6): 54 ̄59.

[15] ZENG S Hꎬ SHEN M Xꎬ XUE Y Jꎬ et al. A novel strategy to rein ̄

force glass fiber fabric / epoxy composites via modifying fibers with

self ̄assembled multi ̄walled carbon nanotubes ̄montmorillonite[ J].

Polymer Compositesꎬ 2020ꎬ 41(2): 522 ̄534.

(上接第 24 页)

5 结 论

本文通过 6 篇文献中的 318 个复材约束海水海

砂混凝土圆柱的试验数据验证了预测其极限应力及

极限应变的 3 组代表性计算模型(Lim 模型、Wei 模

型及 Jiang 模型)的精度ꎬ得到以下结论:

(1)3 组模型在预测极限应力时的精度整体高

于预测极限应变时的精度ꎻ计算极限应力的 3 个模

型的平均绝对误差 AAE 平均值为 13? 8%ꎬ计算极限

应变的 3 个模型的 AAE 平均值为 38? 1%ꎮ

(2)Lim模型在预测极限应力时的 AAE 为10? 7%ꎬ

在预测极限应变时的 AAE 为 27? 8%ꎬ在 3 组模型中

显示出最佳精度ꎬ为预测复材约束海水海砂混凝土

极限状态的最优模型ꎮ

(3)Jiang 模型在预测极限应力时与 Lim 模型取

得相似的高精度ꎬAAE 为 11? 0%ꎬ且模型表达式简

便易算ꎬ也可用来计算复材约束海水海砂混凝土的

极限应力ꎬ但 Jiang 模型低估了极限应变ꎬ在 3 组极

限应变模型中误差最大ꎬ预测值与试验值比值的平

均值 Mean 为 52? 2%ꎮ

(4)Wei 模型对极限应力及极限应变的预测值

与试验值相比整体偏低ꎬ预测值与试验值比值的平

均值 Mean 分别为 81? 0%和 74? 5%ꎮ

参考文献

[1] 何志标. CFRP 约束海水海砂混凝土圆柱轴压力学性能研究

[D]. 广州: 广东工业大学ꎬ 2018.

[2] YANG J Lꎬ WANG J Zꎬ WANG Z R. Axial compressive behavior of

partially CFRP confined seawater sea ̄sand concrete in circular col ̄

umns ̄Part Ⅰ: Experimental study[J]. Composite Structuresꎬ 2020ꎬ

246: 112373.

[3] 曾繁新. FRP 约束模拟海砂混凝土圆柱轴压性能研究[D]. 温

州: 温州大学ꎬ 2017.

[4] 袁逸. FRP 约束模拟海水混凝土标准圆柱轴压性能研究[D]. 温

州: 温州大学ꎬ 2018.

[ 5] ZENG J Jꎬ GAO W Yꎬ DUAN Z Jꎬ et al. Axial compressive behavior

of polyethylene terephthalate / carbon FRP ̄confined seawater sea ̄

sand concrete in circular columns [ J]. Construction and Building

Materialsꎬ 2020ꎬ 234: 117383.

[6] WANG Jꎬ FENG Pꎬ HAO Tꎬ et al. Axial compressive behavior of

seawater coral aggregate concrete ̄filled FRP tubes[ J]. Construction

and Building Materialsꎬ 2017ꎬ 147: 272 ̄285.

[7] OZBAKKALOGLU Tꎬ LIM J C. Axial compressive behavior of FRP ̄

confined concrete: Experimental test database and a new design ̄ori ̄

ented model[J]. Composites Part B ̄Engineeringꎬ 2013ꎬ 55: 607 ̄634.

[8] WEI Y Yꎬ WU Y F. Unified stress ̄strain model of concrete for FRP ̄

confined columns[ J]. Construction and Building Materialsꎬ 2012ꎬ

26(1): 381 ̄392.

[9] JIANG Tꎬ TENG J G. Analysis ̄oriented stress ̄strain models for FRP ̄

confined concrete [ J]. Engineering Structuresꎬ 2007ꎬ 29 ( 11 ):

2968 ̄2986.

[10] LIM J Cꎬ OZBAKKALOGLU T. Design model for FRP ̄confined

normal ̄ and high ̄strength concrete square and rectangular columns

[J]. Magazine of Concrete Researchꎬ 2014ꎬ 66(20): 1020 ̄1035.

[11] 詹瑒ꎬ 李奔奔ꎬ 崔璟ꎬ 等. 双轴对称截面 FRP 轴心受压杆件整

体屈曲临界力计算方法分析[ J]. 复合材料科学与工程ꎬ 2021

(6): 58 ̄64.

[12] LIM J Cꎬ KARAKUS Mꎬ OZBAKKALOGLU T. Evaluation of ulti ̄

mate conditions of FRP ̄confined concrete columns using genetic

programming[J]. Computers and Structuresꎬ 2016ꎬ 162: 28 ̄37.

[13] FAM A Zꎬ RIZKALLA S H. Confinement model for axially loaded

concrete confined by circular fiber ̄reinforced polymer tubes [ J].

ACI Structural Journalꎬ 2001ꎬ 98(4): 451 ̄461.

[14] 张冰ꎬ 赵庆ꎬ 黄涛ꎬ 等. ±60°缠绕的纤维复材管约束混凝土短

柱轴压试验研究[J]. 工业建筑ꎬ 2017ꎬ 47(11): 35 ̄40ꎬ 72.

[15] 李鹏. GFRP 管约束海砂再生混凝土轴压力学性能研究[D].

青岛: 山东科技大学ꎬ 2019.

2021 年第 12 期 59

???????????????????????????????????????????????

破片和爆炸波联合加载下 UHMWPE 纤维复合材料失效行为实验研究

DOI:10? 19936 / j? cnki? 2096 ̄8000? 20211228? 009

破片和爆炸波联合加载下 UHMWPE 纤维复合材料失效行为实验研究

苏罗川ꎬ 田立智ꎬ 宜晨虹∗

ꎬ 刘文杰ꎬ 师亚琴

(中国工程物理研究院 流体物理研究所ꎬ 绵阳 621900)

摘要: 由于超高的比拉伸强度ꎬ超高分子量聚乙烯(Ultra ̄High Molecular Weight Polyethyleneꎬ简称“UHMWPE”)纤维复合

材料在冲击防护领域获得了极大的关注ꎮ 本文通过可同时产生破片和爆炸波加载装置的设计ꎬ实验观察了 UHMWPE 纤维复

合材料在联合冲击加载下的失效行为ꎮ 实验发现ꎬUHMWPE 复合材料在联合加载下失效模式复杂ꎬ包括层间脱层、屈曲与褶

皱、侵彻穿透、纤维烧蚀等ꎮ 基于失效模式的分析ꎬ总结了 UHMWPE 纤维复合材料在破片和爆炸波联合加载下失效破坏的四

个典型阶段ꎮ

关键词: UHMWPE 复合板ꎻ 失效行为ꎻ 破片ꎻ 爆炸波

中图分类号: TB332 文献标识码: A 文章编号: 2096-8000(2021)12-0060-06

Experimental investigations on the failure behaviour of UHMWPE

composite panel under the loading of fragments and blast

SU Luo ̄chuanꎬ TIAN Li ̄zhiꎬ YI Chen ̄hong

∗

ꎬ LIU Wen ̄jieꎬ SHI Ya ̄qin

(Institute of Fluid Physicsꎬ China Academy of Engineering Physicsꎬ Mianyang 621900ꎬ China)

Abstract:Due to the extremely high specific strengthꎬ the ultra ̄high molecular weight polyethylene (UHM ̄

WPE) fiber reinforced laminates are widely employed in protective armors. In this paperꎬ the failure modes of UH ̄

MWPE laminate panel under explosive loading are experimentally investigated. Firstlyꎬ an explosive device that can

simultaneously produce blast and fragments is designed. And thenꎬ the deformation and failure characteristics of the

UHMWPE panel under the loading of the explosive device are gained and analyzed. The panel exhibits multiple fail ̄

ure modesꎬ including the delaminationꎬ bucklingꎬ bubblingꎬ fragments penetration and erosion. Based on the de ̄

formation characteristicsꎬ the failure progress of the UHMWPE laminate panel under explosive loading can be divid ̄

ed into four typical stages.

Key words:UHMWPE composite panelꎻ failure behaviourꎻ fragmentsꎻ blast

收稿日期: 2021 ̄04 ̄20

基金项目: 国家自然科学基金青年项目 (11602246)

作者简介: 苏罗川 (1986 ̄)ꎬ 男ꎬ 博士ꎬ 副研究员ꎬ 研究方向为轻质防护结构设计及优化ꎮ

通讯作者: 宜晨虹 (1976 ̄)ꎬ 男ꎬ 博士ꎬ 副研究员ꎬ 研究方向为冲击动力学ꎬ yichenhong@163? comꎮ

1 引 言

作为比拉伸强度最高的可用工程材料之一ꎬ超

高分子量聚乙烯纤维(Ultra ̄High Molecular Weight Po ̄

lyethyleneꎬ简称“UHMWPE”) 在冲击防护领域的应

用潜力引起了世界各国科研及工程技术人员的广泛

关注[1 ̄3]

ꎮ UHMWPE 纤维密度约为 0? 97 g / cm

3

ꎬ抗拉

强度达 GPa 量级ꎬ远优于目前常用的工程材料ꎮ 研

究表明ꎬ以聚氨酯为基质ꎬ将 10 μm ~ 20 μm 直径的

UHMWPE 纤维按照[0°/ 90°]n方向交叉铺层后热压

形成的叠层复合板(纤维的体积含量约为 85%)能展

现出极强的冲击防护性能ꎬ尤其在侵彻防护方面[4 ̄6]

ꎮ

近年来ꎬUHMWPE 复合材料在侵彻作用下的动

态响应及失效行为受到了科研人员的重点关注ꎮ

Greenhalgh 等[7] 基于实验观察揭示了 UHMWPE 复

合材料在弹体侵彻下的不同失效模式ꎬ包括层间脱

层撕裂、纤维扭曲等ꎬ同时发现复合板的损伤响应过

程与其加工过程相关ꎮ Russell 等[8] 研究认为ꎬ相比

于传统的±45

o纤维铺设方式ꎬ纤维在 0°/ 90°铺设时

复合板性能更优ꎮ Zhang 等[9] 和 Nguyen 等[10] 的实

验显示纤维的铺设方向、边界约束及板厚等因素会

较为显著地影响复合板在弹体侵彻下的变形与失

效ꎮ 而 Attwood 等[11]的工作则直接总结回答了 UH ̄

MWPE 复合板的主要侵彻防护失效机理为间接拉伸

导致的纤维断裂ꎬ即侵彻体的冲击作用使得其接触

60 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

点下方的纤维层处于压缩状态ꎬ而 UHMWPE 复合

材料内各纤维层的泊松膨胀系数在平行和垂直纤维

方向存在较大的差异ꎬ这使被压缩纤维层的侧向膨

胀引发与其垂直的相邻纤维层产生拉伸应力ꎬ当拉

伸应力达到纤维的断裂强度时ꎬ纤维开始出现断裂ꎬ

进而侵彻体继续冲击下方的纤维层ꎻ而一旦冲击带

来的压缩应力不足以引发使纤维断裂的拉应力时ꎬ

侵彻体被阻止ꎮ 这也有力解释了 UHMWPE 纤维的

高抗拉强度在其侵彻防护上的作用ꎮ

基于上述动态响应过程及侵彻防护机理的揭示ꎬ

以 UHMWPE 纤维复合材料为主体的多种侵彻防护

结构被研究人员提出ꎬ并在实验中证实了因其超高

的抗拉强度而带来的良好防护效能[12 ̄14]

ꎮ 需要指出

的是ꎬ在很多实际防护场景中(例如爆炸防护)ꎬ防

护结构会同时遭遇高速破片和爆炸波的联合冲击ꎬ

而在现有的公开报道中ꎬ少有讨论 UHMWPE 这类

防护优势材料在破片和爆炸波联合加载下的失效问

题ꎮ 因此ꎬ本文通过爆炸加载实验的设计ꎬ系统观察

了 UHMWPE 复合板在破片和爆炸波联合加载下的

失效行为ꎬ总结了复合板的主要失效模式及过程ꎮ

2 实验材料与方法

实验中的 UHMWPE 复合板采用 Dyneema 系列

的商业产品ꎮ 复合板试样的尺寸为300 mm×300 mm×

10 mm 的方形板ꎬ板材的整体密度约为 0? 98 g / cm

3

ꎮ

为模拟破片和爆炸波联合加载的情形ꎬ实验采

用图 1 所示的爆炸加载装置ꎮ 装置由钢质柱形外壳

内填充 TNT 炸药组成ꎬ在柱形炸药的两端面用雷管

同时起爆ꎬ内部炸药起爆后驱动钢质外壳运动从而

产生破片和爆炸波ꎮ

图 1 爆炸实验装置及实验现场布局图

Fig? 1 The explosive device used in experiments

依据外部钢壳的材料及厚度的差别ꎬ共开展四

个不同实验ꎬ实验装置的具体参数如表 1 所示ꎮ 所

有实验中钢柱壳的内径和长度均保持不变ꎬ因此ꎬ

TNT 当量均为 1 kgꎮ

表 1 爆炸装置相关参数列表

Table 1 The geometry parameters of the explosive devices

编 号 壳体材料 内径 r/ mm 外径 R/ mm 长度 L / mm 厚度 h / mm

1 Si ̄Mn 钢 25 30.5 240 5.5

2 Si ̄Mn 钢 25 33.5 240 8.5

3 45#钢 25 30.5 240 5.5

4 45#钢 25 33.5 240 8.5

实验在专门的爆炸场地开展ꎬ现场布局如图 1

所示ꎮ UHMWPE 复合板由背部的柔性沙袋支撑ꎬ表

面与装置的轴向平行ꎬ复合板中心距装置中心的距

离为 2 mꎮ 为收集破片的形状ꎬ在爆炸装置的下方

放置一沙箱ꎮ 同时沿爆炸装置表面处布置 PDV 激

光探针ꎬ用于获取爆炸后破片飞出时的速度ꎮ

3 实验结果

四个不同实验测试获取的装置外壳速度历程曲

线如图 2 所示ꎮ 曲线中的速度值随着时间连续变化

后出现中止ꎬ该处为外壳产生的破片撞击探针后导

致的探针损毁ꎬ本文中近似认为该速度为破片侵彻

复合板的入射速度值ꎮ 从曲线可以看出ꎬ速度曲线与

壳体的材料无关ꎬ只与外壳的厚度值相关ꎮ 对于较

厚的外壳(对应表 1 中 h = 8? 5 mm)ꎬ破片速度约为

1? 0 km/ sꎻ对于较薄的外壳(对应表 1 中 h = 5? 5 mm)ꎬ

破片速度约为 1? 3 km / sꎮ 此外ꎬ图 3 给出了实验中

回收的破片形貌及质量信息ꎮ 根据统计ꎬ对于较厚

的外壳装置ꎬ破片质量主要介于 2 g~9 g 之间ꎻ对于较

薄的外壳装置ꎬ破片质量主要介于 1 g~5 g 之间ꎮ

图 2 爆炸装置外壳测速曲线

Fig? 2 The velocity history of the shell checked by PDV probes

2021 年第 12 期 61

???????????????????????????????????????????????

破片和爆炸波联合加载下 UHMWPE 纤维复合材料失效行为实验研究

图 3 实验回收的外壳破片及其质量分布信息

Fig? 3 Typical morphology and mass of the collected fragments

如前所述ꎬ本文的主要目的是观察 UHMWPE

复合板在破片和爆炸波加载下的变形失效行为ꎬ因

此ꎬ后续将重点展示复合板的主要变形及失效特征ꎮ

3? 1 整体变形特征

尽管实验中采用了四种不同的加载装置ꎬ但对

于四块 UHMWPE 复合板而言ꎬ均发生了显著的整

体变形ꎬ主要表现为由爆炸冲击波导致的大范围不

可逆弯曲以及高速破片引发的局部侵彻击穿ꎮ 图 4

展示了其中两块复合板的典型变形形貌ꎮ

图 4 破片和爆炸波联合加载下 UHMWPE

复合板变形形貌图

Fig? 4 The macroscopic deformation characteristics of the

laminate panel under the explosive loading

在图 4 中ꎬ用圆圈单独标出了破片侵彻的部位ꎬ

其中实线圆圈表示侵彻部位被完全贯穿ꎬ虚线圆圈

表示侵彻部位未被贯穿ꎮ 从图 4(a)及图 4(b)中两

块复合板正面和背面的侵彻点数量可以看出ꎬ各自

分别只有两个点和三个点被完全击穿ꎬ绝大多数侵

彻点未能贯穿复合板ꎬ即复合板实现了对绝大多数

破片的有效防护ꎬ展现出了良好的防护效能ꎮ 除局

部部位的侵彻外ꎬ复合板还存在因爆炸波加载导致

的整体弯曲变形ꎬ这种变形虽然并未导致复合板出

现破坏性的损伤ꎬ但这是复合板吸收爆炸冲击能量

的重要模式[1]

ꎮ 不管是侵彻点位的局部变形还是整

体的不可逆弯曲变形ꎬ都是 UHMWPE 复合板吸收

冲击能量的有效方式ꎮ

上述复合板整体的变形特点反映出 UHMWPE

复合板在破片和爆炸波联合作用下具有较好的吸能

防护特性ꎮ 为深入认识 UHMWPE 复合板在联合冲

击下的失效过程以帮助相关工程结构的设计ꎬ接下

来将进一步讨论复合板的详细失效模式ꎮ

3? 2 脱层与屈曲

从实验后复合板的变形情况可见ꎬ复合板层间

的脱层及屈曲现象非常显著ꎬ特别是在边缘区域ꎮ

图 5(a)中展示了相关细节ꎬ可以看到ꎬ在边界处ꎬ屈

曲和脱层二者总是伴随发生ꎮ 此外ꎬ通过图 5(b)中

复合板背部的侵彻点处变形可以发现在侵彻点周围

也伴随着大量的屈曲变形发生ꎮ 进一步从侵彻点的

形貌特点可以看出ꎬ此处的屈曲也伴随着复合板层

间的脱层发生ꎮ 另一个重要现象是ꎬ复合板层间脱

62 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

层主要集中于靠近背部的区域ꎬ该现象主要由冲击

带来的压缩应力在背板自由表面处产生反射拉伸应

力而引起ꎬ因此脱层主要集中于靠近背板的区域ꎮ

对于破片和爆炸波二者的加载ꎬ都能在复合板内部

产生压缩应力进而在边缘处产生反射拉应力ꎬ因此ꎬ

两种加载都会导致复合板层间脱层的出现ꎮ

图 5 复合板边界处的脱层和屈曲(a)ꎬ

以及背部侵彻点周围的屈曲现象(b)

Fig? 5 The delamination and buckling at the boundary

of the panel (a)ꎬ and the buckling appearing at the

penetration sites of the rear face (b)

从能量吸收的角度ꎬ脱层和屈曲对于复合板防护

性能的发挥都是有益的ꎬ都能吸收冲击能量ꎮ 但是ꎬ

该两种失效模式都会影响复合板的抗侵彻性能ꎮ 如

图 6 所示ꎬ侵彻穿孔部位的细节形貌反映出复合板

内部的亚层结构及纤维并未按照最有利于其抗侵彻

性能发挥的模式发生变形及失效ꎮ 基于相关研究ꎬ

复合板内部亚层结构间相互膨胀挤压引起的间接拉

伸模式是 UHMWPE 复合板抗侵彻的基础ꎬ而复合

板层间的良好紧密黏结是保证间接拉伸模式出现的

必要条件[4]

ꎮ 因此ꎬ爆炸波诱发的层间脱层在一定

程度上导致复合板难以发挥其在抗侵彻上的优势ꎮ

图 6 边界脱层区域处的侵彻穿孔典型形貌

Fig? 6 The typical morphologies of the penetration holes

in the boundary delamination regions

3? 3 侵彻穿孔及鼓包

本部分主要分析讨论侵彻部位的穿孔及鼓包现

象ꎮ 不同复合板背部的形貌如图 7 所示ꎮ 对于破片

完全击穿复合板的位置ꎬ在侵彻孔周边具有非常明

显的面外凸起变形ꎻ对于未完全击穿的区域ꎬ侵彻导

致了明显的鼓包ꎬ鼓包的最大挠度值接近两倍复合

板厚度ꎬ这表明 UHMWPE 复合板具有良好的韧性ꎮ

此外ꎬ从图 7(c)和图 7(d)可以看到ꎬ部分未击穿区

域的鼓包与击穿孔非常靠近ꎬ这表明 UHMWPE 复

合板局部的侵彻贯穿失效不会降低相邻区域的侵彻

防护能力ꎬ该特点利于其对多破片侵彻的防护ꎮ

进一步地ꎬ图 7(e)和图 7(f)展示了鼓包及穿孔

部位的截面图ꎮ 在图 7(e)中ꎬ复合板成功阻止了破

片的侵彻ꎬ破片下方产生的面外大挠度变形以及层

间的良好黏结保证了 UHMWPE 能发挥出其基于间

接拉伸的良好抗侵彻性能ꎬ进而纤维的高拉伸强度

能发挥其在破片侵彻防护上的功效ꎮ 相反地ꎬ从图

7(f)中的侵彻孔截面并未看到明显的面外挠度变

形ꎬ该变形特点阻止了纤维发挥其预期的侵彻防护

效能ꎬ进而破片较为轻松地穿透了复合板ꎮ

图 7 复合板背部侵彻穿孔区域的典型形貌

(a)、(b)、(c)、(d)以及侵彻穿孔部位的截面图(e)、(f)

Fig? 7 The typical morphologies of the perforation and bubble

in the rear face (a)ꎬ (b)ꎬ (c) and (d)ꎬ and the sectional

views of the penetration holes (e) and (f)

3? 4 高温烧蚀

相比于传统的弹道实验ꎬ本文实验加载的重要特

征之一是破片在爆炸波加载下呈现出明显的高温特

性ꎬ即破片在侵彻复合板之前已被爆炸过程加热至

较高温度ꎮ 通常情况下ꎬ爆炸过程诱导的破片温度

高达数百摄氏度ꎮ 相关研究表明 UHMWPE 纤维对

温度较为敏感ꎬ因此ꎬ纤维在高温破片作用下出现的

烧蚀效应不可忽略ꎮ 图 8 展示了图 7( e)中侵彻孔

部位的 SEM 图像ꎮ 可以明显发现ꎬ大多数纤维出现

了烧蚀断裂的特征ꎬ进而导致其直接失去了抗侵彻

能力ꎮ 需要指出的是ꎬ烧蚀失效通常发生在破片侵

彻的初始阶段ꎬ随着侵彻过程的深入ꎬ破片温度逐渐

降低ꎬ高温烧蚀将不再是主要的失效模式ꎮ

2021 年第 12 期 63

???????????????????????????????????????????????

破片和爆炸波联合加载下 UHMWPE 纤维复合材料失效行为实验研究

图 8 侵彻区域内部对应图 7(e)侵彻孔的 SEM 图像

Fig? 8 The SEM photographs of the penetration

regions in Fig.7 (e)

4 分析与讨论

基于上述提到的主要变形特征和失效模式ꎬ可

分析获取 UHMWPE 复合板在破片和爆炸波联合加

载下的失效过程ꎮ 整体上讲ꎬUHMWPE 复合板的失

效过程可分为四个主要阶段ꎬ如图 9 所示ꎮ

图 9 UHMWPE 复合板在联合冲击加载下的失效过程

Fig? 9 The failure progress of the UHMWPE

panel under the explosive loading

在初始阶段ꎬ如图 9( a)所示ꎬ由破片和爆炸波

冲击复合板带来的压缩应力沿厚度方向传播ꎬ并且

该压缩应力波在到达复合板背部后反射变为拉伸应

力ꎮ 因此ꎬ拉应力导致的脱层失效将出现在靠近背

部的区域ꎬ特别是复合板的边缘处ꎮ 伴随着脱层的发

生ꎬ破片侵彻进入复合板内部ꎬ见图 9(b)ꎬ在破片进入

复合板的早期阶段ꎬ复合板来不及产生较为明显的

面外变形ꎬ高温高速破片诱发的纤维剪切及烧蚀断

裂成为该阶段的主要失效模式ꎮ 而随着破片侵彻深

度的增加ꎬ复合板在冲击作用下逐渐产生明显的面

外变形ꎬ此时失效模式开始发生变化ꎮ如图9(c)所示ꎬ

UHMWPE 纤维复合材料开始展现出最为典型的间

接拉伸失效模式ꎬ纤维的抗拉强度在侵彻防护中发

挥主导作用ꎮ 当间接拉伸产生的拉应力低于纤维的

拉伸强度时ꎬ破片侵彻过程被阻止ꎻ而当间接拉伸产

生的拉应力高于纤维的拉伸强度时ꎬ破片会继续向

前侵彻直至贯穿整个复合板ꎮ 在该过程中沿侵彻穿

孔区域周围出现明显的屈曲及脱层失效ꎬ见图 9(d)ꎮ

5 结 论

本文基于爆炸实验ꎬ系统观察了 UHMWPE 复合

板在破片和爆炸波联合作用下的变形行为及主要失

效模式ꎮ 结果表明ꎬUHMWPE 复合板在联合加载下

呈现复杂的失效模式ꎬ包括脱层、屈曲、鼓包、穿孔以

及纤维烧蚀断裂等ꎮ 联合加载下ꎬ复合板的失效过程

可分为四个主要阶段ꎮ 初始阶段ꎬ破片和爆炸波冲击

带来的压缩应力波在复合板背部发生反射拉伸造成

复合板靠近背部区域出现明显的脱层现象ꎻ当高温

破片开始侵彻进入复合板内部后ꎬ内部纤维的剪切

和烧蚀断裂成为主要失效模式ꎻ而随着侵彻过程的

进行ꎬ复合板逐渐产生较大的面外变形ꎬUHMWPE 纤

维复合材料开始展示出其特有的间接拉伸失效模式ꎬ

阻止破片侵彻ꎻ若破片能量足够高ꎬ其最终将穿透复

合板ꎬ此时穿孔周围将伴随明显的屈曲及脱层失效ꎮ

参考文献

[1] FALLAH A Sꎬ MICALLEF Kꎬ LANGDON G Sꎬ et al. Dynamic re ̄

sponse of dyneema HB26 plates to localised blast loading[J]. Inter ̄

national Journal of Impact Engineeringꎬ 2014ꎬ 73(1): 91 ̄100.

[2] CHOCRON Sꎬ KING Nꎬ BIGGER Rꎬ et al. Impacts and waves in

Dyneema

® HB80 strips and laminates[ J]. Journal of Applied Me ̄

chanicsꎬ 2013ꎬ 80(3): 472 ̄481.

[3] 张颖异ꎬ 李冰川ꎬ 刘发杰. PE ̄UHMW 抗弹复合材料及其在防护

领域中的应用[J]. 工程塑料应用ꎬ 2015ꎬ 43(10): 143 ̄146.

[4] O′MASTA M Rꎬ CRAYTON D Hꎬ DESHPANDE V Sꎬ et al. Mech ̄

anisms of penetration in polyethylene reinforced cross ̄ply laminates

[J]. International Journal of Impact Engineeringꎬ 2015ꎬ 86: 249 ̄264.

[5] 李翠玉ꎬ 杨雪ꎬ 冯亚男ꎬ 等. 不同层数的超高分子量聚乙烯纬平

针织复合材料冲击损伤[J]. 复合材料学报ꎬ 2015ꎬ32(2): 557 ̄564.

[6] 苏罗川ꎬ 宜晨虹ꎬ 刘文杰. 超高分子量聚乙烯纤维复合材料的应

用及其抗侵彻性能[J]. 化工新型材料ꎬ 2019ꎬ 47(1): 198 ̄201.

[7] GREENHALGH E Sꎬ BLOODWORTH V Mꎬ LIANNUCCIA Lꎬ et

al. Fractographic observations on Dyneema composites under ballistic

64 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

impact[J]. Composites Part A: Applied Science and Manufacturingꎬ

2013ꎬ 44: 51 ̄62.

[8] RUSSELL B Pꎬ KARTHIKEYAN Kꎬ DESHPANDE V Sꎬ et al. The

high strain rate response of ultra high molecular ̄weight polyethylene:

From fibre to laminate[J]. International Journal of Impact Engineer ̄

ingꎬ 2013ꎬ 60: 1 ̄9.

[9] ZHANG T Gꎬ SATAPATHY S Sꎬ VARGAS ̄GONZALEZ L Rꎬ et al.

Ballistic impact response of Ultra ̄High ̄Molecular ̄Weight Polyethylene

(UHMWPE)[J]. Composite Structuresꎬ 2015ꎬ 133: 191 ̄201.

[10] NGUYEN L Hꎬ RYAN Sꎬ CMPOERU S Jꎬ et al. The effect of target

thickness on the ballistic performance of ultra high molecular weight

polyethylene composite[J]. International Journal of Impact Engineer ̄

ingꎬ 2015ꎬ 75: 174 ̄183.

[11] ATTWOOD J Pꎬ RUSSELL B Pꎬ WADLEY H N Gꎬ et al. Mecha ̄

nisms of the penetration of ultra ̄high molecular weight polyethylene

composite beams[ J]. International Journal of Impact Engineeringꎬ

2016ꎬ 93: 153 ̄165.

[12] O′MASTA M Rꎬ COMPTON B Gꎬ GAMBLE E Aꎬ et al. Ballistic

impact response of an UHMWPE fiber reinforced laminate encasing

of an aluminum ̄alumina hybrid panel [ J]. International Journal of

Impact Engineeringꎬ 2015ꎬ 86: 131 ̄144.

[13] 李典ꎬ 侯海量ꎬ 朱锡ꎬ 等. 舰船装甲防护结构抗弹道冲击的研

究进展[J]. 中国造船ꎬ 2018ꎬ 59(1): 237 ̄250.

[14] 李典ꎬ 侯海量ꎬ 戴文喜ꎬ 等. 爆炸冲击波和破片联合作用下玻璃

纤维夹芯复合结构毁伤特性实验研究[J]. 兵工学报ꎬ 2017ꎬ 38

(5): 877 ̄885.

[15] ZHANG Rꎬ QIANG L Sꎬ HAN Bꎬ et al. Ballistic performance of

UHMWPE laminated plates and UHMWPE encapsulated aluminum

structures: Numerical simulation[J]. Composite Structuresꎬ 2020ꎬ

252: 112686.

(上接第 33 页)

6 结 论

可扁平输送软管的承压强度取决于织物增强层

的拉伸性能ꎬ而在纱线交叉点产生的应力集中会降

低织物的强度ꎮ 本文通过研究织物结构参数与纱线

交叉点处应力集中程度的关系ꎬ为优化织物增强层

结构ꎬ改善可扁平输送软管的承压性能提供了依据ꎮ

结果表明:斜纹环编织物有限元拉伸模拟结果和拉

伸试验结果基本相符ꎻ织物承受经向拉伸载荷时ꎬ经

纱间距、纬纱细度、纬纱卷曲率大小对交叉点处的应

力集中程度没有明显影响ꎻ织物承受纬向拉伸载荷

时ꎬ经纱间距增大、纬纱变细以及纬纱卷曲率降低可

以使纱线交叉点处的应力分布更加均匀ꎬ提高纱线

力学效率ꎬ纬纱卷曲率大于 4? 1%时ꎬ经纱间距、纬纱

细度以及纬纱卷曲率对交叉点处的应力集中程度影

响较大ꎮ

参考文献

[1] 谭凤旭ꎬ 杨立明. 高技术在外军油料补给装备上的应用[ J]. 现

代军事ꎬ 2000(7): 22 ̄23.

[2] 黄忠耀ꎬ 蔡利海ꎬ 蔡宝祥ꎬ 等. 一种多层筒形织物的设计方法:

2014104441910[P]. 2015 ̄01 ̄07.

[3] COIMBRA R Nꎬ OTERO M. A continuous process for the production

of a fabric reinforced polymeric matrix [ J]. Journal of Reinforced

Plastics and Compositesꎬ 2015ꎬ 34(20): 1662 ̄1672.

[4] 孙训方. 材料力学 ̄Ⅰ[M]. 北京: 高等教育出版社ꎬ 2009.

[5] 刘倩楠ꎬ 张涵ꎬ 刘新金ꎬ 等. 基于 ABAQUS 的三原组织机织物拉

伸力学性能模拟[J]. 纺织学报ꎬ 2019ꎬ 40(4): 44 ̄50.

[ 6] 李瑛慧ꎬ 谢春萍ꎬ 刘新金. 三原组织织物拉伸力学性能有限元仿

真[J]. 纺织学报ꎬ 2017ꎬ 38(11): 41 ̄47.

[7] CARVELLI Vꎬ CORAZZA Cꎬ POGGI C. Mechanical modelling of

monofilament technical textiles[J]. Computational Materials Scienceꎬ

2008ꎬ 42(4): 679 ̄691.

[8] SU Xꎬ LIU X. Dynamic tensile process of blended fabric using finite

element method [ J]. International Journal of Clothing Science and

Technologyꎬ 2020ꎬ 32(5): 707 ̄724.

[9] CHEN Sꎬ TIAN Xꎬ HUA Tꎬ et al. Exploring the relationship between

applied fabric strain and resultant local yarn strain within the elastic

fabric based on finite element method[ J]. Journal of Materials Sci ̄

enceꎬ 2020ꎬ 55(23): 10258 ̄10270.

[10] 赵书经. 纺织材料实验教程[M]. 北京: 中国纺织出版社ꎬ 1989.

[11] 顾平. 织物组织与结构学[M]. 上海: 东华大学出版社ꎬ 2010.

[12] 周炬. ANSYS Workbench 有限元分析实例详解: 静力学[ M].

北京: 人民邮电出版社ꎬ 2017.

[13] CARVELLI Vꎬ POGGI C. A homogenization procedure for the nu ̄

merical analysis of woven fabric composites[J]. Composites. Part Aꎬ

Applied Science and Manufacturingꎬ 2001ꎬ 32(10): 1425 ̄1432.

[14] DUAN Yꎬ KEEFE Mꎬ BOGETTI T Aꎬ et al. A numerical investiga ̄

tion of the influence of friction on energy absorption by a high ̄strength

fabric subjected to ballistic impact[J]. International Journal of Im ̄

pact Engineeringꎬ 2004ꎬ 32(8): 1299 ̄1312.

[15] 徐燕娜ꎬ 葛明桥. 夜光纤维摩擦与耐磨损性能研究[J]. 针织工

业ꎬ 2008(4): 17 ̄19.

[16] SHEN Yꎬ MEIR A Jꎬ CAO Y Zꎬ et al. Finite element analysis of

monofilament woven fabrics under uniaxial tension[J]. The Journal

of The Textile Instituteꎬ 2015ꎬ 106(1): 90 ̄100.

[17] FREDERICK T P. 5 ̄The geometry of cloth structure[J]. Journal of

the Textile Institute Transactionsꎬ 1937ꎬ 28(3): 45 ̄96.

2021 年第 12 期 65

???????????????????????????????????????????????

用于雷达天线的国产碳纤维预浸料成型工艺优化及配套材料优选

DOI:10? 19936 / j? cnki? 2096 ̄8000? 20211228? 010

用于雷达天线的国产碳纤维预浸料成型工艺优化及配套材料优选

孙 坤1ꎬ2

ꎬ 赵文忠1ꎬ2

ꎬ 张晨晖1ꎬ2

ꎬ 刘明昌1ꎬ2

ꎬ 李建伟1ꎬ2

ꎬ 高 琦1ꎬ2

ꎬ 许培伦1ꎬ2

(1? 中国电子科技集团公司第二十研究所ꎬ 西安 710068ꎻ 2? 中电科西北集团有限公司ꎬ 西安 710068)

摘要: 为实现国产碳纤维/ 环氧树脂织物预浸料在雷达天线中的应用ꎬ开展以该碳纤维预浸料为蒙皮的夹层板热压罐成

型工艺流程和关键工艺参数优化研究ꎬ在此基础上ꎬ制备 6 种以碳纤维预浸料为蒙皮ꎬ分别以 J ̄95 或 SY ̄24C Ⅱ胶膜进行胶接ꎬ

填充 J ̄47D 或 SY ̄P6 发泡胶或不填充发泡胶的复合材料夹层板ꎬ通过平面拉伸、弯曲等力学性能测试分析对该预浸料用于夹

层板时的配套材料进行优选研究ꎮ 研究结果确定采用两步热压罐法进行不填充发泡胶和填充 J ̄47D 发泡胶的夹层板成型ꎬ采

用三步热压罐法进行填充 SY ̄P6 发泡胶的夹层板成型ꎬ并确定升/ 降温速率、加压时机等关键工艺参数和工装辅助等提高夹层

板质量的措施ꎻ对 6 种夹层板力学性能测试分析发现ꎬSY ̄24C Ⅱ胶膜与蒙皮、蜂窝以及发泡胶的匹配性更好ꎮ 而将两型发泡

胶相比ꎬ填充 SY ̄P6 发泡胶的夹层板的各项力学性能明显更优ꎬ因此优选 SY ̄24C Ⅱ胶膜和 SY ̄P6 发泡胶作为配套材料用于雷

达天线制造ꎮ

关键词: 碳纤维复合材料ꎻ 夹层板ꎻ 工艺优化ꎻ 配套材料ꎻ 力学性能

中图分类号: TB332 文献标识码: A 文章编号: 2096-8000(2021)12-0066-07

Optimization of forming process and supporting materials of

domestic carbon fiber prepreg for radar antenna

SUN Kun

1ꎬ2

ꎬ ZHAO Wen ̄zhong

1ꎬ2

ꎬ ZHANG Chen ̄hui

1ꎬ2

ꎬ LIU Ming ̄chang

1ꎬ2

ꎬ

LI Jian ̄wei

1ꎬ2

ꎬ GAO Qi

1ꎬ2

ꎬ XU Pei ̄lun

1ꎬ2

(1? The 20th Research Institute of China Electronics Technology Group Corporationꎬ Xi′an 710068ꎬ Chinaꎻ

2? China Electronics Technology Northwest Group Corporationꎬ Xi′an 710068ꎬ China)

Abstract:In order to realize the application of domestic developed carbon fiber/ epoxy resin fabric prepreg in

radar antennaꎬ the forming process and key process parameters optimization of sandwich plate autoclave with new ̄

developed carbon fiber prepreg as skin were studied. On this basisꎬ six kinds of composite sandwich panels were

prepared with newly prepared carbon fiber prepreg as skinꎬ bonded with J ̄95 or SY ̄24C Ⅱ filmꎬ filled with J ̄47D

or SY ̄P6 foam or not filled with foam. Through the test and analysis of plane tensile and bending mechanical proper ̄

tiesꎬ the supporting materials of the prepreg used in sandwich plate were optimized. The results of the study showed

that the two ̄step autoclave forming process was used to form the sandwich board without foam or the sandwich board

filled with J ̄47D foam and the three ̄step autoclave forming process was used to form the sandwich board filled with

SY ̄P6 foam. In additionꎬ the key process parametersꎬ such as the rate of heating or coolingꎬ the pressure timingꎬ

and the measures to improve the quality of sandwich panelꎬ such as tooling assistanceꎬ were determined. The me ̄

chanical properties of six kinds of sandwich panels were tested and analyzed. It was found that SY ̄24C Ⅱ film had a

better match with skinꎬ honeycomb and foamꎬ and compared with the two types of foamꎬ the mechanical properties

of the sandwich board filled with SY ̄P6 foam are obviously better. Thereforeꎬ SY ̄24C Ⅱ film and SY ̄P6 foam are

determined as supporting materials for the manufacture of radar antenna.

Key words:carbon fiber compositesꎻ sandwich panelsꎻ process optimizationꎻ supporting materialsꎻ mechanical

properties

收稿日期: 2021 ̄07 ̄05

基金项目: 国防科研项目 (TDXX ̄CL ̄19 ̄0XX ̄2)

作者简介: 孙坤 (1991 ̄)ꎬ 男ꎬ 硕士ꎬ 工程师ꎬ 主要从事复合材料方面的研究ꎬ MrSkain@163? comꎮ

66 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

碳纤维复合材料夹层板具有构件比重轻、比强度

和模量高、制品成型尺寸稳定性好、可设计性强、抗

疲劳性好、耐腐蚀性优异等优点ꎬ已被作为承力构件

广泛用于飞机、雷达、汽车、高铁等军民品领域[1 ̄3]

ꎮ

某雷达天线为通过热压罐成型方法制成的以碳纤维

复合材料预浸料为蒙皮、LF2Y 耐久铝蜂窝为芯材的

夹层结构ꎬ为满足天线装配和力学性能要求ꎬ通常还

需对夹层板边沿一定宽度填充发泡胶[4ꎬ5]

ꎮ

雷达天线成型过程涉及碳纤维复合材料与耐久

铝蜂窝、胶膜、发泡胶等多种不同特性材料的复合ꎬ

需在热压罐环境中历经多次加压、加热、降温、卸压

等ꎬ工艺过程复杂ꎬ在温度场梯度、固化交联反应、外

压等物理化学因素影响下容易产生热 ̄化学应变、残

余应力和固化变形等[6ꎬ7]

ꎮ 因此ꎬ雷达天线性能与

预浸料、胶膜等材料的特性以及成型工艺等密不可

分ꎬ材料匹配性不佳、工艺流程不合适或固化参数不

恰当ꎬ很难使夹层板性能达到最佳状态ꎬ甚至会引起

翘曲、鼓包ꎬ直接影响最终制件的性能[8 ̄10]

ꎮ

用于该雷达天线蒙皮的 AC319 / CF8010 预浸料

为国产中温固化碳纤维/ 环氧树脂织物预浸料ꎬ尚未

在工程实际中得到应用ꎬ没有可供参考的工程固化

工艺参数ꎬ缺乏发泡胶、胶膜等相关配套材料匹配性

研究技术积累ꎮ 为实现该预浸料在雷达天线中的应

用ꎬ需根据天线实际生产需求ꎬ结合该碳纤维预浸料

与胶膜、发泡胶等配套材料物化性能特点ꎬ开展夹层

板固化工艺流程和关键工艺参数工艺优化研究以及

配套材料优选研究ꎬ确定最佳固化工艺参数和适合

与该碳纤维预浸料配套使用的胶膜、发泡胶型号ꎮ

1 试验方案与方法

1? 1 主要原材料

AC319 / CF8010 碳纤维/ 环氧树脂织物预浸料:

含胶量为 36%ꎬ厚度为(0? 1±0? 01) mmꎬ面密度为

(100±1) g / m

2

ꎬ中国航空制造技术研究院ꎻLF2Y 耐

久铝蜂窝 EL ̄0? 05 ̄4W ̄5A02 ̄2800 ̄W1250 ̄T12ꎬ中航

西安飞机工业集团股份有限公司ꎻJ ̄95 胶膜ꎬ黑龙江

石化院ꎬSY ̄24C Ⅱ胶膜ꎬ中国航发北京航空材料研

究院ꎬ两种胶膜均为中温固化胶膜ꎬ厚度为(0? 20±

0? 02) mmꎻJ ̄47D 发泡胶ꎬ灰色片状ꎬSY ̄P6 发泡胶ꎬ

蓝色粉末状ꎬ两种发泡胶均由中国航发北京航空材

料研究院生产ꎮ

1? 2 试 验

1? 2? 1 工艺优化试验

针对天线使用需求ꎬ开展填充或不填充发泡胶

的夹层板固化工艺优化试验ꎬ根据预浸料等固化特

性参数ꎬ初步采用两步法成型夹层板ꎬ即先通过热压

罐成型两张蒙皮ꎬ再通过热压罐进行蒙皮与蜂窝芯

材的二次胶接[11]

ꎮ 单张蒙皮由 4 层预浸料铺贴而

成ꎬ固化温度和压力分别为 400 kPa、135 ℃ ꎬ保温

180 minꎬ蒙皮与蜂窝胶接温度和压力分别为 150 ℃、

135 ℃ꎬ保温 120 minꎮ

根据蒙皮是否翘曲、蒙皮与蜂窝胶接是否可靠、

夹层板是否有鼓包或凹陷等缺陷ꎬ针对性地进行成

型工艺优化ꎬ如加强升/ 降温速率和升/ 降压速率的

控制以及升/ 降温时间的选择等ꎻ同时ꎬ加强工艺过

程控制ꎬ采取工装、匀压板等措施确保夹层板外观质

量满足要求ꎮ

1? 2? 2 配套材料优选试验

初选 J ̄95 和 SY ̄24C Ⅱ胶膜及 J ̄47D、SY ̄P6 发

泡胶ꎬ按照工艺优化试验确定的夹层板成型工艺参

数和相关措施进行夹层板成型ꎬ采取先成型夹层板ꎬ

再机械加工测试样件的工艺流程ꎬ制备 6 种分别以

不同胶膜胶接、填充不同发泡胶或不填充发泡胶的

夹层板ꎬ通过对夹层板平面拉伸等力学性能测试分

析ꎬ对碳纤维复合材料与配套材料的匹配性进行优

选研究ꎬ夹层板尺寸为 600 mm×750 mmꎬ确保可裁

剪出各类性能测试样件ꎮ 配套材料优选试验方案如

表 1 所示ꎮ

表 1 碳纤维复合材料与配套材料优选试验方案

Table 1 Optimal test scheme of carbon fiber

composites and supporting materials

序 号 蒙 皮 芯 材 胶 膜 发泡胶 编 号

1

2

3

4

5

6

AC319 /

CF8010

LF2Y

铝蜂窝

J ̄95 无 J0

SY ̄24C Ⅱ 无 S0

J ̄95 J ̄47D JJ

J ̄95 SY ̄P6 JS

SY ̄24C Ⅱ J ̄47D SJ

SY ̄24C Ⅱ SY ̄P6 SS

1? 3 夹层板性能测试分析

通过平面拉伸、平面压缩、平面剪切、侧向压缩、

弯曲 5 项试验测试上述 6 种夹层板常温力学性能ꎬ平

面拉伸等 5 项试验依次按照 GB/ T 1452、GB/ T 1453、

GB/ T 1454、GB/ T 1455、GB/ T 1456 进行ꎬ试验在 SANS

CMT 5105 型电子万能试验机上进行ꎬ每种试样不少

于 5 件ꎮ 按照相关标准要求ꎬ机加工制备相应尺寸的

力学性能测试样件ꎮ 测试完成后根据相应标准依次

计算夹层结构抗平拉强度、芯子压缩强度、剪切强度、

2021 年第 12 期 67

???????????????????????????????????????????????

用于雷达天线的国产碳纤维预浸料成型工艺优化及配套材料优选

侧压强度、芯子剪切强度及夹层结构弯曲刚度ꎮ 通

过上述力学性能分析评估ꎬ确定最终优选匹配方案ꎮ

2 结果与讨论

2? 1 夹层板成型工艺优化

2? 1? 1 无填充发泡胶的夹层板

初步试验时出现夹层板翘曲、部分蒙皮与蜂窝

脱胶及夹层板边缘部分蜂格塌陷等问题ꎮ 非对称铺

层易产生应力不均ꎬ造成制件变形ꎬ为减少铺层带来

的变形[12ꎬ13]

ꎬ蒙皮按照“0°/ +45°/ -45°/ +90°” 方式

对称铺贴ꎻ为确保人工下料时纤维方向准确性和一

致性ꎬ下料时ꎬ采用定向限位下料工装辅助ꎮ 为保证

固化过程真空度符合设置要求ꎬ真空袋封装完进热

压罐前ꎬ必须通过关闭真空泵的保压测试来排除偶

然因素导致的真空袋“漏气” 现象ꎬ同时ꎬ真空度设

置为-98 kPaꎬ并采取先加压再升温和预固化的方式

确保蒙皮层间密实、无气泡ꎮ 蒙皮固化时采取零吸胶

工艺ꎬ保证蒙皮含胶量与前期摸底试验的一致[14]

ꎮ

为减少温度梯度和压力梯度引起的内应力ꎬ升/ 降温

速率分别降为 1 ℃ / min、-1 ℃ / minꎬ升/ 降压速率分

别减至 30 kPa / min、-50 kPa / minꎬ并采取阶梯式升/

降温方式ꎬ确保温度场的均匀性ꎮ 蒙皮固化工艺参

数设置如表 2 所示ꎮ

表 2 蒙皮固化时的固化工艺参数设置

Table 2 Setting of curing process parameters during skin curing

程序段

空气温度

/ ℃

模具温度

/ ℃

罐内压力

/ kPa

真空度

/ kPa

保温时间

/ min

1 45 25 400 -98 0

2 90 80 400 -98 0

3 82 80 400 -98 30

4 135 128 400 -98 0

5 135 130 400 -98 180

6 40 60 0 -98 0

针对夹层板的翘曲和部分蜂格塌陷等问题ꎬ对

蒙皮与蜂窝胶接时的真空度、升/ 降温速率、升/ 降压

速率等进行同步调整ꎬ同时ꎬ合理设计辅料铺贴方

式ꎬ如针对蒙皮表面光亮不利于粘接的问题ꎬ蒙皮固

化时ꎬ在预浸料表面依次铺贴隔离布和无孔膜ꎬ同步

实现蒙皮零吸胶和粗化ꎬ提高其可粘性ꎬ避免人工打

磨粗化的不均匀性ꎬ并采取工艺框辅助、匀压板均压

等措施避免蜂格塌陷ꎬ提高夹层板质量ꎮ

2? 1? 2 填充发泡胶的夹层板成型

初步采用两步法成型填充发泡胶的夹层板时ꎬ

发现填充 J ̄47D 发泡胶的夹层板表面平整ꎬ无鼓包

或凹坑ꎬ但发泡胶填充不够密实ꎬ蜂格内存在空洞ꎮ

这主要是由蜂格填充高度控制不当引起的ꎬ同时ꎬJ ̄

47D 呈片状ꎬ料粒尺寸分布宽ꎬ填充时部分尺寸较大

的料粒易发生“架桥”ꎮ 在后续填充时ꎬ采取机械粉

碎和过筛等方式控制料粒尺寸ꎻ发泡胶填充时ꎬ为确

保发泡胶恰好充实蜂格ꎬ料粒应填充至距蜂格上沿

2 mm~5 mmꎮ

两步法成型的填充 SY ̄P6 发泡胶的夹层板出现

大面积蒙皮鼓包ꎬ破坏蒙皮后发现鼓包处发泡胶未

充实蜂格ꎬ而未鼓包处蜂窝填充密实ꎬ破坏为蒙皮层

间剥离或发泡胶被拉断ꎬ详见图 1ꎮ 这可能是 SY ̄P6

固化过程中逸出的小分子气体被裹缚在蒙皮内或残

留在状胶料内的空气在蒙皮与蜂窝间的聚集造成

的ꎬ但通过加匀压板和延长抽真空时间等措施减少

真空袋内空气残留并不能解决蒙皮鼓包问题[15ꎬ16]

ꎮ

为此ꎬ采用先进行一侧蒙皮与蜂窝胶接(同时进行

SY ̄P6 的填充固化)ꎬ再进行另一层蒙皮与蜂窝胶接

的分步法进行夹层板复合ꎮ 但实际操作过程中发

现ꎬ在一侧蒙皮与蜂窝胶接后ꎬ蜂窝板仅单侧受力ꎬ

向无蒙皮一侧大幅收缩变形ꎬ严重翘曲ꎬ无法进行上

蒙皮的胶接固化ꎮ

图 1 鼓包夹层板及部分蒙皮破坏后外观图

Fig? 1 Appearance of bulge sandwich panel

and part of skin damaged

为解决上述问题ꎬ进一步优化填充 SY ̄P6 的夹

层板成型工艺ꎬ采取先固化蒙皮ꎬ并单独进行 SY ̄P6

的填充固化ꎬ然后进行蒙皮与已填充固化 SY ̄P6 的

蜂窝的胶接复合ꎮ 实践中为保证 SY ̄P6 固化后恰好

填平蜂格ꎬ胶料填充时ꎬ将铝蜂窝芯放置于平板模具

上ꎬ四周采用工艺框围挡ꎬ蜂格用胶料填平ꎬ并采用

匀压板确保压力均匀ꎮ SY ̄P6 固化后硬度高ꎬ为避

免残留在模具上的胶料打磨清理困难ꎬ同时增加发

泡胶与蒙皮胶接时的表面粗糙度ꎬ发泡胶填充时及

时清理蜂格以外发泡胶粉末ꎬ并在蜂窝两侧铺贴隔

68 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

离布ꎬ提高可粘性ꎮ 胶料发泡固化温度和压力分别

为 200 kPa、135 ℃ ꎬ保温 120 minꎻ真空度设置为-95

kPaꎬ升/ 降温速率分别设置为 2 ℃ / min、-2 ℃ / minꎬ

升/ 降压速率分别设置为 50 kPa / min、 - 100 kPa /

minꎮ 检查发现上述方法制备的夹层板蒙皮平整、无

鼓包、无凹陷ꎬ破坏蒙皮后发现发泡胶填充密实ꎬ破

坏为蒙皮层间剥离或发泡胶被拉断ꎬ同时ꎬ断面无

空洞ꎮ

基于上述工艺优化试验并兼顾生产效率和生产

成本ꎬ确定填充 J ̄47D 的夹层板和无填充的夹层板ꎬ

采用两步热压罐法成型ꎬ而填充 SY ̄P6 的夹层板采

用三步法成型ꎮ 相应力学性能测试样件制备工艺流

程如图 2、图 3 所示ꎮ

图 2 填充 J ̄47D 或无填充的夹层板成型工艺流程

Fig? 2 Forming process of sandwich plate filled

with J ̄47D or without filling

图 3 填充 SY ̄P6 的夹层板成型工艺流程

Fig? 3 Forming process of sandwich plate filled with SY ̄P6

2? 2 性能测试结果分析

2? 2? 1 平面拉伸性能测试及分析

平面拉伸试验主要考察试样的平拉强度和破坏

形式ꎬ胶接为弱连接ꎬ通过该测试可以分析评估两种

胶膜与碳纤维复合材料、铝蜂窝及发泡胶的匹配性ꎮ

不同夹层结构平面拉伸强度见图 4ꎬ部分试样平面

拉伸破坏情况如图 5 所示ꎬ根据结果可知ꎬJ0 试样蒙

皮与芯材部分脱胶ꎬ平拉强度为 1? 82 MPaꎬ且离散

系数过大(Cv

= 16? 47%)ꎬS0 试样以蜂窝局部破坏

为主ꎬ平拉强度为 3? 86 MPaꎬ表明 SY ̄24C Ⅱ胶膜与

纯铝蜂窝胶接的抗平拉性能更优ꎮ 填充 J ̄47D 的 JJ

和 SJ 试样均为蒙皮与蜂窝芯胶接处破坏ꎬ平拉强度

相差不大且与 S0 相近ꎻ填充 SY ̄P6 的 JS、SS 试样为

蒙皮分层破坏或芯层与蒙皮胶接面破坏ꎬ平拉强度

分别为 7? 56 MPa、8? 22 MPaꎬ说明 SY ̄P6 与 J ̄95、

SY ̄24C Ⅱ两型胶膜胶接时的抗平拉性能较 J ̄47D

的好ꎮ 分析可知:无论是否填充发泡胶ꎬSY ̄24C Ⅱ

胶接的试样抗平拉强度都更高ꎻ两型发泡胶相比ꎬ填

充 SY ̄P6 的试样平拉性能更高ꎮ

图 4 不同夹层结构试样平面拉伸强度

Fig? 4 Tensile strength of specimens with

different sandwich structures in plane

图 5 部分夹层结构平面拉伸试验破坏试样

Fig? 5 Failure specimens of some sandwich

structures in plane tensile tests

2? 2? 2 平面压缩性能测试及分析

平面压缩试验主要考察夹层板平压载荷的承载

能力ꎬ据此可分析两型发泡胶性能的优劣ꎮ 不同夹

层结构平面压缩强度见图 6ꎬ部分试样平面压缩破

坏情况见图 7ꎬ由图可知ꎬJ0、S0 试样均为铝蜂窝坍

塌破坏ꎬ平压强度基本一致ꎬ分别为 2? 21 MPa 和 2? 33

MPaꎮ 填充发泡胶后平压载荷由发泡胶和蜂窝壁同

时承载ꎬ且 J ̄47D、SY ̄P6 均为环氧类ꎬ发泡后自身强

度较高ꎬ能快速吸收能量和分散压力ꎬ因此抗平压强

度显著增加ꎮ 填充 J ̄47D 的 JJ、SJ 试样平压强度分

别为 7? 01 MPa 和 5? 87 MPaꎬ较未填充的提高 2 倍以

上ꎬ分析认为两种试样强度的差异与采用 J ̄47D 填

充时微孔的随机性有关ꎻ填充 SY ̄P6 的 JS、SS 试样

2021 年第 12 期 69

???????????????????????????????????????????????

用于雷达天线的国产碳纤维预浸料成型工艺优化及配套材料优选

的平压强度相当ꎬ分别为 33? 01 MPa 和 33? 44 MPaꎬ

比填充 J ̄47D 的提高 4 倍以上ꎬ这与料粒尺寸有关ꎬ

J ̄47D 填充时虽已机械粉碎ꎬ但其尺寸远大于粉状

SY ̄P6ꎬ固化后微孔的存在使其抗压强度较后者低ꎮ

根据上述分析可知ꎬ两种胶膜的夹层板抗平压性能

无明显差异ꎬ但两型发泡胶相比ꎬ填充 SY ̄P6 的试样

具有更强的抗平压性能ꎮ

图 6 不同夹层结构试样平面压缩强度

Fig? 6 Plane compressive strength of samples

with different sandwich structures

图 7 部分夹层板平面压缩试验破坏试样

Fig? 7 Failure samples of some sandwich panels

in plane compression test

2? 2? 3 平面剪切性能测试及分析

平面剪切试验主要考察夹层结构的平面剪切强

度和破坏形式ꎬ据此可评估两种胶膜与碳纤维复合

材料、铝蜂窝及发泡胶的匹配性ꎮ 不同夹层结构平

面剪切强度见图 8ꎬ部分试样平面剪切破坏情况如

图 9 所示ꎬJ0 或 S0 试样破坏发生在胶接面ꎬ胶接强度

分别为 0? 92 MPa、0? 97 MPaꎬ表明两种胶膜与纯铝

蜂窝胶接时的抗平面剪切强度较小且相差不大ꎮ 填

充 J ̄47D 发泡胶的 JJ、SJ 试样均为芯层与蒙皮胶接

处的发泡胶被剪切剥离ꎬ平面剪切强度分别为 2? 99

MPa、2? 65 MPaꎬ比纯铝蜂窝芯子提高 2 倍以上ꎻ填

充 SY ̄P6 的 JS、SS 试样主要为芯层和蒙皮胶接处破

坏、蒙皮剪切破坏等ꎬ剪切强度分别达到 4? 65 MPa

和 4? 51 MPaꎬ比纯铝蜂窝芯的平面剪切强度提高了

3 倍以上ꎬ填充发泡胶后抗剪强度的大幅提高与发泡

胶可以更有效地传递和分散剪切应力ꎬ有效防止蜂

窝壁过早剪切失稳有关ꎮ 根据上述可知ꎬ不填充或

填充 SY ̄P6 时ꎬ两种胶膜胶接的夹层板的抗平面剪

切性能无明显差异(平面剪切强度相差接近 5%)ꎬ

但填充 J ̄47D 时ꎬ采用 J ̄95 的夹层板平面剪切性能

更优ꎻ两种发泡胶对试样抗平面剪切性能影响与平

面拉伸试验结果一致ꎬ填充 SY ̄P6 的试样平面剪切

性能更高ꎮ

图 8 不同夹层结构试样平面剪切强度

Fig? 8 Plane shear strength of samples with

different sandwich structures

图 9 部分夹层板平面剪切试验破坏试样

Fig? 9 Failure samples of partial sandwich plates

in plane shear test

70 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

2? 2? 4 侧向压缩性能测试及分析

侧向压缩试验主要考察夹层结构抗侧向压缩载

荷的能力ꎬ据此可分析碳纤维复合材料蒙皮/ 铝蜂窝

与胶膜、发泡胶的匹配性ꎮ 不同夹层结构侧向压缩

强度见图 10ꎬSJ 试样侧向压缩破坏情况见图 11ꎬ侧

向加载条件下ꎬJ0、S0 试样载荷主要由两侧蒙皮承

载ꎬ试样均为端部蒙皮压缩破坏ꎬ侧压强度分别为

12? 34 MPa、14? 40 MPaꎮ 填充发泡胶后ꎬ发泡胶可以

分担和传递侧压载荷ꎬ夹层板侧压强度明显提高ꎮ

填充 J ̄47D 的 JJ、SJ 侧压强度分别为 25? 20 MPa、

25? 52 MPaꎬ较未填充的提高 2 倍以上ꎬ填充 SY ̄P6

发泡胶的 JS、SS 侧压强度分别为 34? 86 MPa、36? 65

MPaꎬ较填充 J ̄47D 的提高 50%左右ꎬ分析认为两种

发泡胶填充的试样的侧压强度的差异也与 J ̄47D 料

粒尺寸较大有关ꎮ 分析可知ꎬ两种胶膜相比ꎬSY ̄24C

Ⅱ胶接的夹层板抗侧压性能更好ꎬ两型发泡胶相比ꎬ

SY ̄P6 填充的夹层板抗侧向压缩性能更优ꎮ

图 10 六种不同夹层结构试样侧压强度

Fig? 10 Side compressive strength of samples with

different sandwich structures

图 11 SJ 夹层板侧向压缩试验破坏试样

Fig? 11 Specimens in lateral compression test of SJ sandwich plate

2? 2? 5 弯曲性能测试及分析

弯曲试验主要通过分析芯材剪切强度、夹层板

弯曲刚度ꎬ对碳纤维复合材料蒙皮、铝蜂窝与胶膜和

发泡胶的匹配性进行进一步评估ꎮ 不同夹层结构芯

材剪切强度、夹层板弯曲刚度分别见图 12、图 13ꎬ部

分试样弯曲破坏情况见图 14ꎬJ0、S0 均在弯曲载荷

加载处出现屈服变形ꎬ两种夹层板芯材的剪切强度

分别为 0? 87 MPa、0? 95 MPaꎬ弯曲刚度分别为 1? 33×

10

5

kN?mm

2

、1? 27×10

5

kN?mm

2

ꎮ 填充发泡胶后ꎬ复

合材料蒙皮、蜂窝芯和发泡胶共同承担弯曲载荷ꎬ芯

材剪切强度增加ꎬ因此ꎬ夹层结构抗剪切能力显著增

强ꎬ填充 J ̄47D 的 JJ、SJ 试样剪切强度分别为 3? 23

MPa、3? 21 MPaꎬ较未填充的提高近 4 倍ꎻ填充 SY ̄

P6 的 JS、SS 试样多在载荷加载处发生破坏ꎬ芯材剪

切强度均为 3? 83 MPaꎬ较未填充的提高 4 倍以上ꎮ

弯曲刚度主要用以评价夹层板抵抗弯曲变形的能

力ꎬ填充发泡胶后ꎬ整体抗弯曲变形能力增强ꎬ所以

试样弯曲刚度增加ꎬ填充 J ̄47D 的 JJ、SJ 试样弯曲刚

度分别为 1? 32×10

5

kN?mm

2

、1? 48×10

5

kN?mm

2

ꎻ填

充 SY ̄P6 的 JS、SS 试样弯曲刚度分别为 1? 85×10

5

kN?mm

2

、1? 69×10

5

kN?mm

2

ꎮ 分析可知ꎬ无填充或

填充 SY ̄P6 发泡胶时ꎬ采用不同种胶膜胶接的夹层

结构抗剪切性能和抗弯曲性能无明显差异ꎻ而填充

J ̄47D 发泡胶时ꎬSY ̄24C Ⅱ型胶接的夹层板抗弯曲

变形能力略强ꎬ但两种胶膜对芯材抗剪切性能无明

显影响ꎻ而胶膜相同时ꎬSY ̄P6 发泡胶填充的夹层板

抗剪切性能和抗弯曲变形性能更优ꎮ

图 12 六种不同夹层结构试样蜂窝芯材剪切强度

Fig? 12 Shear strength of honeycomb core material of

samples with different sandwich structures

图 13 六种不同夹层结构试样弯曲刚度

Fig? 13 Bending stiffness of specimens of

different sandwich structures

2021 年第 12 期 71

???????????????????????????????????????????????

用于雷达天线的国产碳纤维预浸料成型工艺优化及配套材料优选

图 14 部分夹层板弯曲试验破坏试样

Fig? 14 Failure samples of some sandwich plates in bending test

综合上述分析发现ꎬ只在填充 J ̄47D 时ꎬ采用 J ̄95

胶接的夹层板的平面剪切性能相对较好ꎬ其余情况

下ꎬSY ̄24C Ⅱ胶接的夹层板综合性能更为优异ꎬ表

明 SY ̄24C Ⅱ胶膜与蒙皮、蜂窝以及 SY ̄P6 发泡胶

的匹配性更好ꎮ 而两型发泡胶相比ꎬSY ̄P6 使用方

便ꎬ填充 SY ̄P6 发泡胶夹层板的平拉强度、平面压缩

强度等性能均明显优于 J ̄47Dꎮ

3 结 论

本文通过对国产碳纤维/ 环氧树脂织物预浸料

开展夹层结构成型工艺优化及配套材料优选研究ꎬ

得到如下结论:

(1)通过开展不填充和填充发泡胶的夹层板固

化工艺优化研究ꎬ确定了采用两步热压罐法进行不

填充发泡胶和填充 J ̄47D 发泡胶的夹层板成型ꎬ采

用三步热压罐成型法进行填充 SY ̄P6 发泡胶的夹层

板成型ꎬ优化了升/ 降温速率、升/ 降压速率、加压时

机、真空度等关键工艺参数ꎬ确定了工装辅助、辅料

铺贴、精细化控制等确保夹层板质量一致性的工艺

措施ꎮ

(2)通过对 J0、JJ 等 6 种夹层结构的五项力学性

能测试和综合分析ꎬ发现 SY ̄24C Ⅱ胶接的夹层板综

合性能更为优异ꎬ表明其与蒙皮、蜂窝以及发泡胶的

匹配性更好ꎻ而将两型发泡胶相比ꎬ填充 SY ̄P6 发泡

胶的夹层板的各项力学性能明显更优ꎬ因此优选

SY ̄24C Ⅱ胶膜和 SY ̄P6 发泡胶作为配套材料用于

雷达天线制造ꎮ

参考文献

[1] 徐樑华. 高性能 PAN 基碳纤维国产化进展及发展趋势[J]. 中国

材料进展ꎬ 2012ꎬ 31(10): 7 ̄13.

[2] 朱苗ꎬ 刘刚ꎬ 党婧. 尾翼盒段主承力结构用高温固化碳纤维复合

材料性能应用研究[J]. 宇航材料工艺ꎬ 2019ꎬ 49(2): 82 ̄85.

[3] 徐林ꎬ 王树浩ꎬ 蔡东旭ꎬ 等. 低密度碳纤维复合材料耐高温抗氧

化技术研究[J]. 稀有金属材料与工程ꎬ 2019ꎬ 48(11): 260 ̄267.

[4] 王伟ꎬ 左小彪ꎬ 冯志海ꎬ 等. 一种玻纤/ 环氧 ̄Nomex 蜂窝夹层复

合材料制备工艺与性能研究[J]. 玻璃钢/ 复合材料ꎬ 2015(10):

42 ̄46.

[5] 李莺歌ꎬ 关鑫ꎬ 陈维强ꎬ 等. 蜂窝夹层结构及其埋件的力学性能

研究[J]. 宇航材料工艺ꎬ 2018(4): 41 ̄45.

[6] 梁恒亮ꎬ 邱海鹏ꎬ 陈静ꎬ 等. 铝蜂窝夹层板正交结构件的制造方

法[J]. 航空制造技术ꎬ 2009(s1): 30 ̄32.

[7] 吴利华ꎬ 张婷. 复合材料热压罐固化工艺研发试验设计与适航

验证[J]. 航空制造技术ꎬ 2018ꎬ 61(19): 88 ̄92ꎬ 97.

[8] 张铖ꎬ 梁宪珠ꎬ 王永贵ꎬ 等. 热压罐工艺环境对于先进复合材料

框架式成型模具温度场的影响[J]. 材料科学与工程学报ꎬ 2011

(4): 547 ̄553.

[9] 赵书婧. 复合材料热压罐固化变形及压实过程分析[D]. 哈尔

滨: 哈尔滨工业大学ꎬ 2011.

[10] 张广成ꎬ 张鸿鸣ꎬ 徐恒元ꎬ 等. 碳纤维/ 环氧树脂超薄预浸料成

型工艺及胶膜匹配性研究[J]. 航空制造技术ꎬ 2018ꎬ 61(14):

38 ̄44.

[11] 袁超ꎬ 张明. 复合材料蜂窝夹层结构方向舵二次胶接成型技术

研究[J]. 科技与创新ꎬ 2019ꎬ 127(7): 98 ̄99.

[12] 陈蔚ꎬ 成理ꎬ 叶宏军ꎬ 等. Nomex 蜂窝夹层复合材料的成型工

艺研究[J]. 玻璃钢/ 复合材料ꎬ 2017(7): 70 ̄73.

[13] 李敏ꎬ 张宝艳. 不对称铺层复合材料变形规律的实验研究[ J].

玻璃钢/ 复合材料ꎬ 2006(5): 28 ̄31.

[14] 王东. 舱段用碳纤维/ 环氧树脂复合材料及其整体成型工艺

[D]. 哈尔滨: 哈尔滨工业大学ꎬ 2010.

[15] 于丽娟. 碳纤维/ 环氧树脂预浸料及其复合材料的成型工艺和

力学性能[D]. 上海: 东华大学ꎬ 2013.

[16] 汪亮ꎬ 孙玲. 变截面蜂窝夹层结构复合材料胶接工艺研究[ J].

玻璃钢/ 复合材料ꎬ 2009(3): 68 ̄70.

72 2021 年 12 月

???????????????????????????????????????????????

复合材料科学与工程

DOI:10? 19936 / j? cnki? 2096 ̄8000? 20211228? 011

基于正交试验法的混杂纤维橡胶混凝土力学性能试验研究

朱鹏宇1

ꎬ 万后林2

ꎬ 朱 叶1

ꎬ 顾文虎1

(1? 淮阴工学院 建筑工程学院ꎬ 淮安 223000ꎻ 2? 江苏东辰建材有限公司ꎬ 淮安 223000)

摘要: 针对混杂纤维橡胶混凝土(HFRC)设计了正交试验ꎬ对其力学性能进行测试并与普通混凝土对比ꎬ分析了玄武岩

纤维体积率、聚丙烯纤维体积率和橡胶体积率对 HFRC 抗压、劈裂抗拉和抗折强度的影响ꎮ 结果表明:当玄武岩纤维体积率为

0? 3%、聚丙烯纤维体积率为 0? 2%、橡胶体积率为 5%时ꎬHFRC 各项性能表现最佳ꎮ 玄武岩纤维对 HFRCꎬ强度的影响程度最大ꎬ

掺入混杂纤维 HFRCꎬ强度有较大幅度提升ꎬ体现了良好的纤维“正混杂效应”ꎬ随着橡胶体积率增加ꎬHFRC 强度逐渐降低ꎮ 借

助 SEM 微观分析了纤维在 HFRC 中的桥接增强作用ꎬ对 HFRC 增韧阻裂机制进行了讨论ꎬ最后对 HFRC 强度进行了模型预测ꎮ

关键词: 混凝土ꎻ 力学性能ꎻ 玄武岩纤维ꎻ 聚丙烯纤维ꎻ 橡胶ꎻ 强度ꎻ SEM 微观分析ꎻ 复合材料

中图分类号: TB332 文献标识码: A 文章编号: 2096-8000(2021)12-0073-05

Experimental study on mechanical properties of hybrid fiber rubber

concrete based on orthogonal experiment

ZHU Peng ̄yu

1

ꎬ WAN Hou ̄lin

2

ꎬ ZHU Ye

1

ꎬ GU Wen ̄hu

1

(1? Faculty of Architecture and Civil Engineeringꎬ Huaiyin Institute of Technologyꎬ Huaian 223000ꎬ Chinaꎻ

2? Jiangsu Dongchen Building Materials Co.ꎬ Ltd.ꎬ Huaian 223000ꎬ China)

Abstract:Orthogonal experiments were designed for hybrid fiber rubber concrete (HFRC)ꎬ and its mechanical