中科坤悦ZHONGKEKUNYUE

中科坤悦(北京)科技有限公司,是一家集工程服务、运营管理服务、装备制造、科技研发孵化及产业化推广为一体的多元化企业。公司与中国科学院山西煤炭化学研究所、中国矿业大学等国内外科研院所及高校深度合作,坚持“固废完全资源化利用”为导向,专注减污降碳技术。

在“双碳”战略目标下,公司致力于矿物资源及大宗固废资源开发利用、二氧化碳减排等技术的研发与推广,提供粗细粒有价矿物分选技术、大宗固废有价组分分离提质技术、二氧化碳捕集及矿化技术,并为尾矿提供一系列材料化制备技术。

公司业务涉及矿物分选,煤研石、气化灰渣、粉煤灰等大宗固废处理,工业废水处理,尾矿资源回收利用等方面,为能源工业化利用过程提供固废清洁高效处理及资源化利用的整体解决方案和全过程服务。

ZHONGKEKUNYUE (Beijing)Technology Co, Ltd. is a diversified enterprise integrating engineering services,operation managementservices,equipmentmanufacturing,technologicalR&D incubation and industrialization promotion.The company collaborates deeplywith researchinstitutions and universities both domestically and internationally,including Institute of Coal Chemistry Chinese Academmy of Sciences and China University of Mining and Technology. Upholding Complete Solid Waste Resource Utization as its guicdingprinciple,thecompanyis dedicated to pollutionreductionand carbonreductiontechnologies.ettru!

Under the Dual Carbon strategicgoats.the comany is commited t the R&D and promotion of technologies for mineralresources andbulksolidwasteresource development andutilization,andcarbondioxide emissionreduction. Itprovidesvaluable mineral sorting technologyfor coarse and fine particles,valuablecomponentseparation and upgroding technologyfor butk solid waste, carbon dioxide capture and mineralization technology.and a series of materialpreparationtechnologiesfortailings.

The companys busnesencompasses minerau sortng bui sold wastetreatment of col gngue gsicatonsig fy ashetc.ndustrialwastewatertreatmentand tailingsresourcerecyclingmong others.tcanprovidecomprehensive solutionsandfull-processservicesforcleanand effcient treatment andresourceutilizationof solid wastein the energy industrialization process.

技撑 SUPPORT TECHNOLOGY

STRONGALLIANCE,ENHANCED R&D CAPABILITIES

公司与中国科学院山西煤炭化学研究所、中国矿业大学等国内外科研院所及高校保持长期合作,形成了多项专利、标准及关键核心技术。公司不断扩大科研队伍、加强自主研发能力和提升新质生产力,全力推进科研成果转化,为双碳目标的实现提供技术保障。

The company maintains long-term cooperation with research institutions and universities both domestically and internationally.including Institute of Coal Chemistry. Chinese Academy of Sciences and China University of Mining andTechnology,resulting innumerous patents,standards,and keycore technologies.The company continuously expands its research team,strengthens independent R&D capabilities, and enhances new quality productive forces. It is fullycommitted to promoting the transformation of scientific research achievements and providing technological support forachieving the"DualCarbon'goals.

企业 ADVANTAGES COMPANY优势

固废利用全产业链

公司专注减污降碳技术,为企业提供精准工程服务规划、专业工程设计与装备制造、完善的服务保障体系以及产业化推广等四大支撑。

The company focuses on pollutionreduction and carbon reduction technologies,strengthening fourkey pillars: precise engineering planning for enterprises, professional engineering design and equipment manufacturing. comprehensive service guarantee system, and industrialization promotion.

{+5} 为需求企业提供量身定制的工程规划,高效解决企业所面临各种固废处理问题

Provides customized engineering plans for demanding enterprises, efficiently solving various solid waste treatmentissuesfaced by enterprises

{+} 为企业提供可靠的工程装备设计与制造,进行安装调试并使用指导

体化 SYSTEM ENGINEERING

各类固废材料化制备

MaterialPreparation fromVariousSolidWastes

科研团队

李磊 研究员/博导

中国科学院青促会会员“三晋英才”获得者

LLei,

Researcher/Doctoral Supervisor, Memberof theYouthInnovation Promotion Association of CAS, Recipient of theSanJin Talents" Program

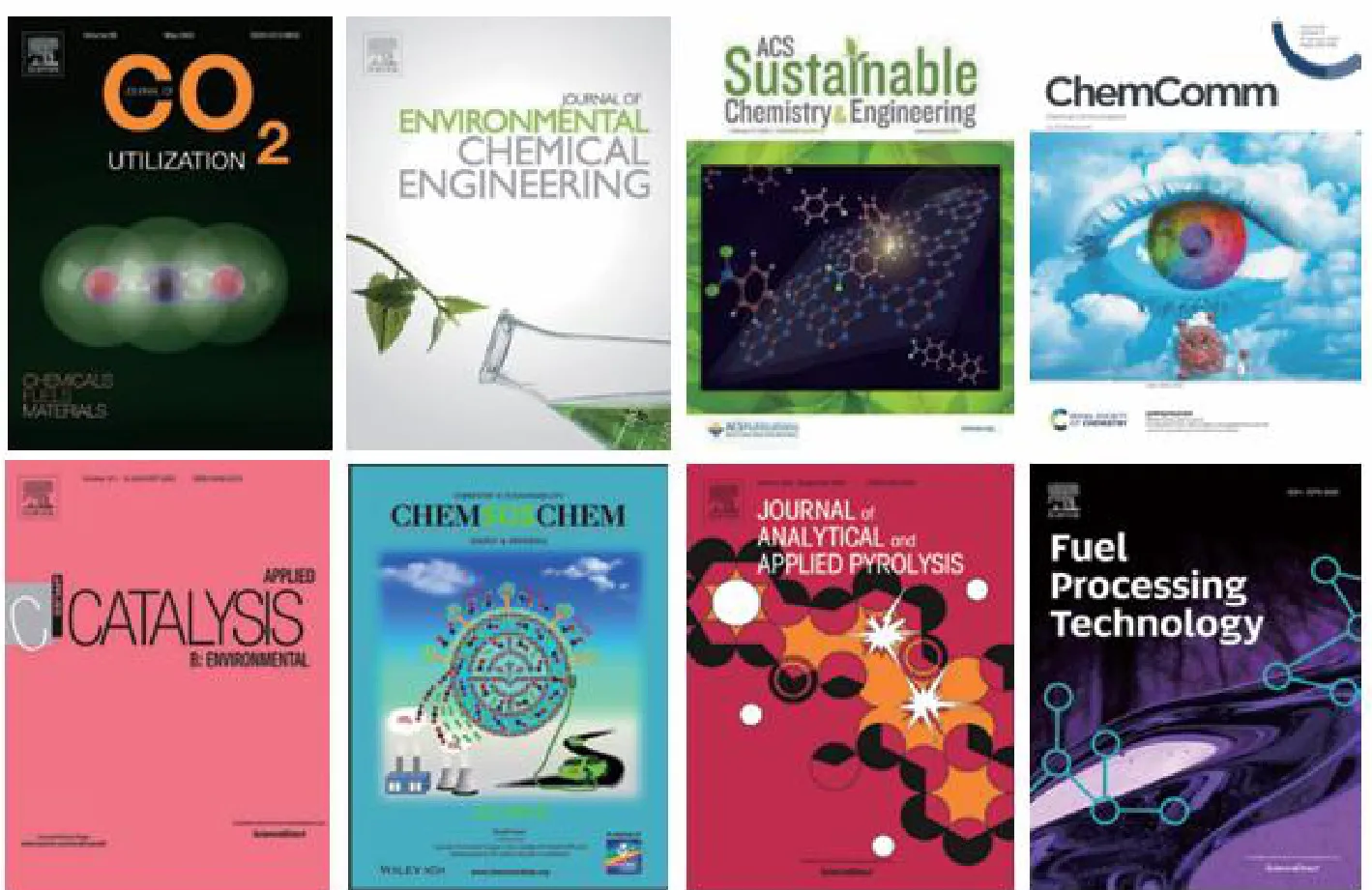

李磊,研究员,博士生导师,任职于中国科学院山西煤炭化学研究所,煤炭高效低碳利用全国重点实验室主任助理,课题组长,入选中国科学院青促会会员、山西省“三晋英才”青年优秀人才计划。担任全国煤化工标准化技术委员会委员、中国能源学会碳中和专业委员会副秘书长以及山西省化学会第九届理事会理事等职务,主要从事CO2捕集及转化、减污降碳以及高端化学品合成方向研究,作为项目负责人承担了项目30余项,完成了多项技术中试与示范。在ACSCatalysis、Applied Catalysis B、The Innovation、Chem.Eng.J.JCO2Uti等期刊发表论文70余篇,申请、授权专利30余项,主持和参与制定标准10余项,获得了国际XPRIZECarbonRemoval中国预热赛TOP10、中国发明协会发明创业奖成果奖一等奖以及中国循环经济协会科技进步二等奖等奖项。

ULeResearcher,Doctoral Supervisor,DirectorAssistantof theStateKey Laboratoryf Coal Efhcient and Clean Conversion, Institute of Coal Chemistry. Chinese Academy of Sciences,and GroupLeader.Selected asa member of theYouth InnovationPromotion Association of the Chinese Academy of Sciences ond the “Son Jin Talents" Youth Outstanding Talent Program in Shanxi Province.Serves as a member of the National Coal Chemical Standardization Technical Committee,Deputy Secretary-General of the Carbon Neutrality Professional Committee of the ChinaEnergy Society.and Director of the 9th Councilof the Shanxi Chemical Society.His research focuses an COa capture and conversion, pollution reduction and carbon reduction, and the synthesis of highend chemicals. As project leoder, he has undertaken over 30 projects and completed multiple technology pilot tests and demonstrations. Has published over 70 popers in journals such as ACs Catalysis, Applied Catalysis B, The Innovation, Chem.EngJ, and J COUtiland applied for and authorized over 30 patents,presided over and partici pated in the formulation of over 10 standards, and won awards including the Intern ational XPRZE Carbon Removal China Pre-Competition TOP10,the FirstPrize of the Invention and Entrepreneurship Award of the China Associotion of Inventions, and the Second Prize of the Science and Technology Progress Award of the China Association of·CircularEconomy.

公司团队负责人

张海军,国家杰出青年科学基金获得者、国家重点研发计划项目首席,现任中国矿业大学化工学院院长。主要从事矿物分离过程强化理论与装备、二次资源综合利用、工业固废资源化方面科研工作。主持或完成国家重点研发计划项目(课题)、国家科技支撑计划课题、国家自然科学基金联合基金重点项目、国家优秀青年科学基金等国家和省部级以上科研项目12项,承担校企重大横向科研项目10余项;第一/通讯作者发表SCI/EI论文80余篇;授权国内外发明专利30余件;获国家科技进步二等奖1项、省部级科技进步二等奖4项、国家行业协会科技进步一等奖6项。

张海军 研究员/博导

国家杰出青年基金获得者中国矿业大学化工学院院长

ZHANG Haijun,

Researcher/Doctoral Supervisor, Recipient of theNational Science Fund for Distinguished Young Scholars

Dean of the School of Chemical Engineering, China University of Mining and Technology

ZHANG Hojun, Recipient of the National Science Fund for Distinguished Young Scholors and Chief Scientist af a Natianal Key R&D Program, Dean of the School of Chemical Engineering and Technology at China University of Mining and Technology. Mainty engoged inresearch on the theory and equipment for strengthening mineral separation processes, comprehensive utilization of secondary resources, and industrial solid waste resource utilizationHas presided over or completed 12 projects including the National Key R&D Program (project) of China,the National Science and Technology Support Program Project, the Joint Fund Key Project of the National Natural Science Foundation of China, the National Excellent Young Scientists Fund Project, and the National Key R&D Program Project, Undertaken more than 10 majorindustry-university collaborative research projects. Has published over 80 Scl/El popers os the first or corresponding outhor, and authorized over 30 domestic and intemotionol invention potents.Aworded 1 Second Prize for National Science and Technology Progress, 4 Second Prizes for Provincial. and Ministerial Science and Technology Progress,and 6 First PrizesforScience and Technology Progress from nationalindustry associations.

技术 TECHNICAL团队

中央电视台、人民网、山西卫视等媒体报道Medio Coverogeby CCTV.People'sDaily Online,ShanxiTV,etc.

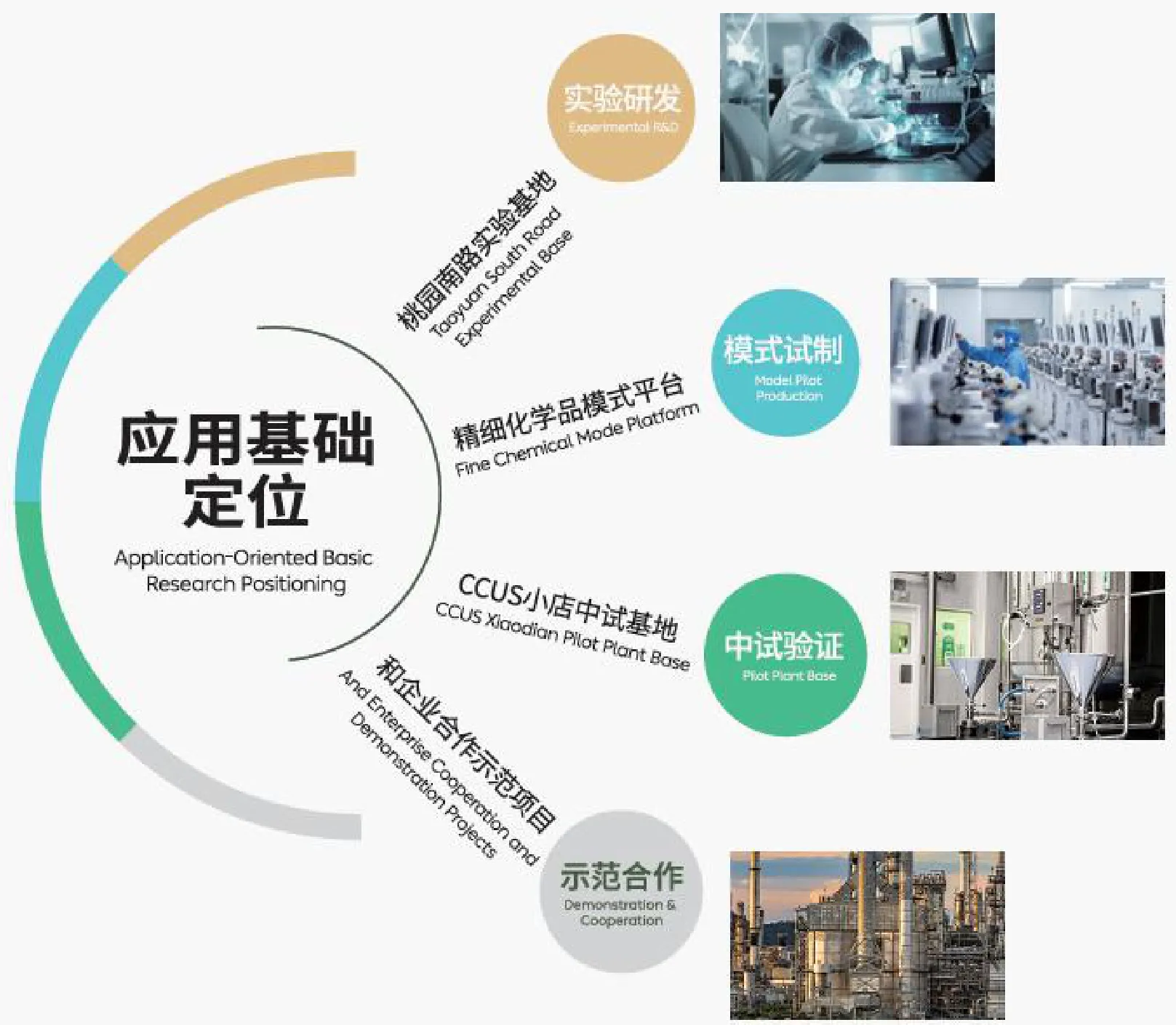

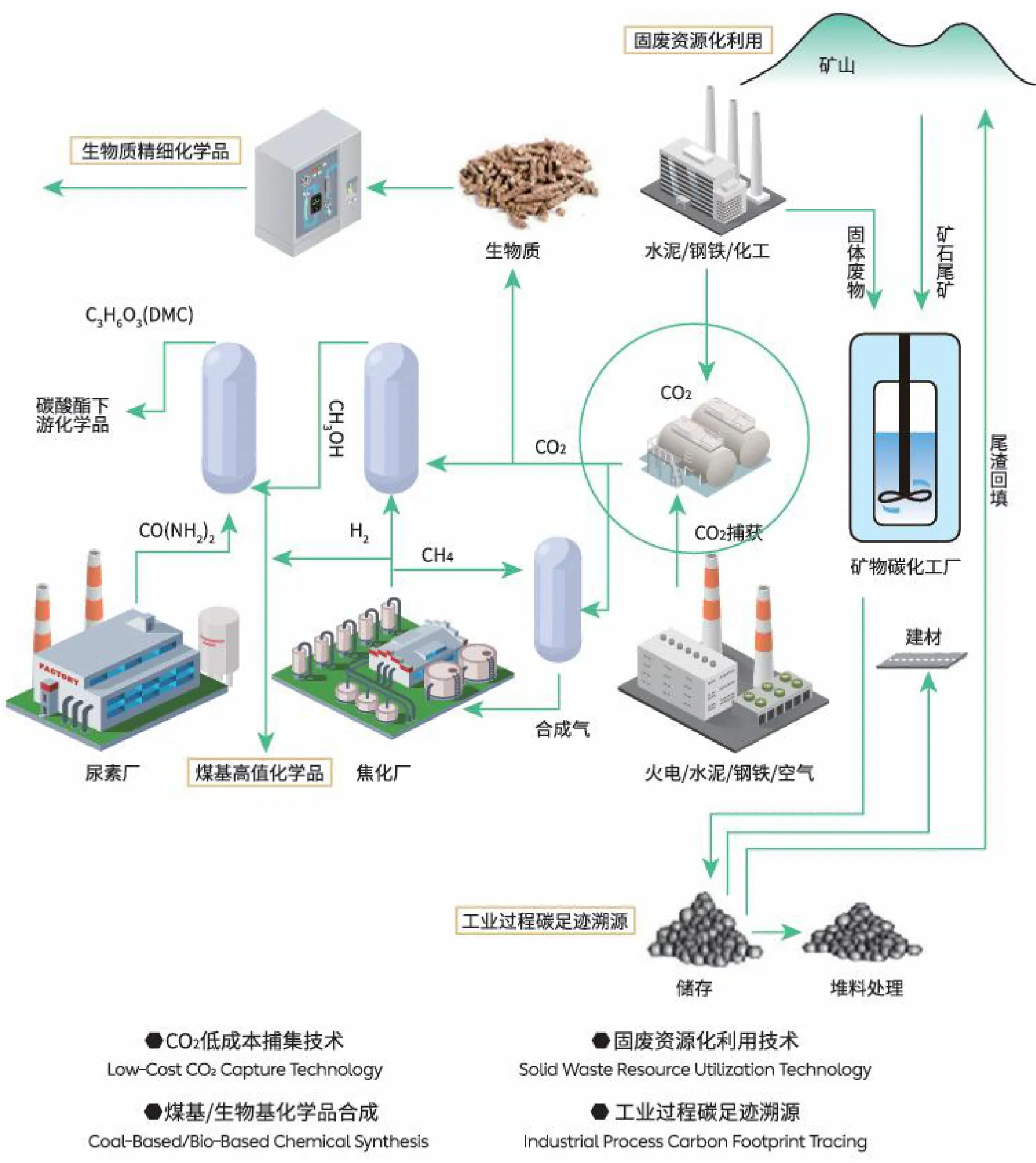

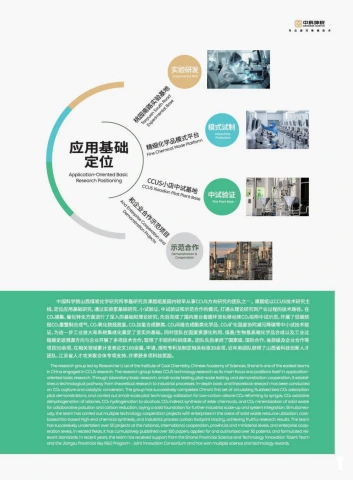

中国科学院山西煤炭化学研究所李混研究员课题组是国内较早从事CCUS方向研究的团队之一。课题组以CCUS技术研究主线,定位应用基础研究,通过实验室基础研究、小试验证、中试验证和示范合作的模式,打通从理论研究到产业过程的技术路径。在CO.捕集、催化转化方面进行了深入的基础和理论研究,先后完成了国内首台套循环流化移动床CO,吸附中试示范,开展了低碳烷经CO.重整制合成气CO.氧化烷经脱氢、CO.加氨合成醇类、CO间接合成酯类化学品、CO.矿化固废协同减污降碳等中小试技术验证,为进一步工业放大和系统集成化奠定了坚实的基础。同时团队在固废资源化利用、煤基/生物基高端化学品合成以及工业过程碳足迹溯源方向与企业开展了多项技术合作,取得了丰硕的科研成果。团队先后承担了国家级、国际合作、省部级及企业合作等项目50余项,在相关领域累计发表论文100余篇,申请、授权专利及制定相关标准30余项,近年来团队获得了山西省科技创新人才团队、江苏省人才攻关联合体专项支持,井荣获多项科技奖励。

TheresearchgroupledbyResearcherLLelofthenstituteofCoalChemistryChneseAcademyofcienceshanxisneftheearliesttems in China engogednCcuSresearchTheresearch group tokesCcus technologyresearchositsmain focus and positions itself inopplicotionorientedbosicreseorchThroughlaborotory basic research,smoll-scole testing.pllot-scale testingand demonstratoncooperation,itestabl sheso technologicolpathwoy from theoreticalreseorch to industrialprocessesIn-depthbosic and theoreticalresearch hosbeenconducted on COcopture and catolytic conversion.The group has successively completed China's frst setof circulating fluidized bed Coadsorption pilot demonstrationsandcaiedout small-scale pilot technologywalidation forlow-carbonalkane COreforming tosyngasCO oxidatve dehydrogenotionofalkanesCOhydrogenation toaicoholsCOindirect synthesisofesterchemicalsandicOmineralizotionaf solidwoste forcollaborotivepollutionandcarbonreductionloyingsolidfoundationforfurtherindustrialscale-upndsystemintegrationSimultane usly.the teamhos carred outmultiple technology cooperation projectswithenterprisesin the oreasof solidwasteresourceutilizationcool bosed/bio-basedhigh-endchemicalsynthesis.and industrial processcorbonfootprinttrocing.ochveving fruitful reseorchresults.The team has successivelyundertoken over 50 prcjects at thenotionointemgtional cooperation,prowincidlcndministerial levels andenterprisecoop erotion levels.Inreloted fields,it has cumulotively pubished over100 popers,pplied forand quthorized over 30 potents,nd formulotedrelevent stondardis.Ihrecentyears,the teamhasreceivedsupport from theShanxiProvincial Science andTechnology lnnovaionTalentTeam ond the JiangsuProvineial Key R&D Program-Joint Innovation Consortium ond has wonmultiple scienceand technologyrowords.

企业荣誉

专利标准及 ANDAWARDS STANDARDS PATENTS荣获奖项

公司获得了多项国内、国际专利,牵头及参与制定多项标准,同时形成了具有自主知识产权的装备及技术。为合作企业提供专业技术支撑和服务,在业内具有优势地位。

The company has obtained numerous domestic and international patents, led and participated in the formulation of multiple standards,and developed equipment and technologieswith independent intellectual property rights.It provides professional technical support and services to partner enterprises and holdsa leadingposition in the industry.

04 成黑留 ACHIEVEMENTS

奇源理固废 WASTETYPES TREATABLESOLIL

以渣固碳、以碳治渣”协同治理

CarbonSequestrationwithWaste,WasteTreatment with Carbon"SynergisticGovernance

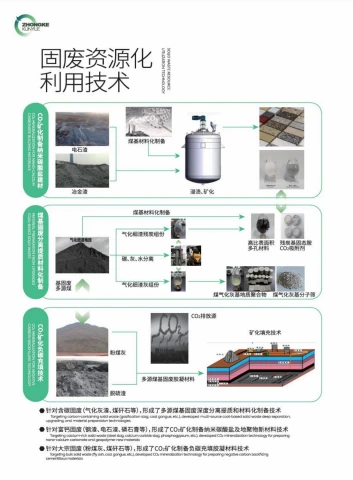

固废资源化利用技术

固废资源化利用技术

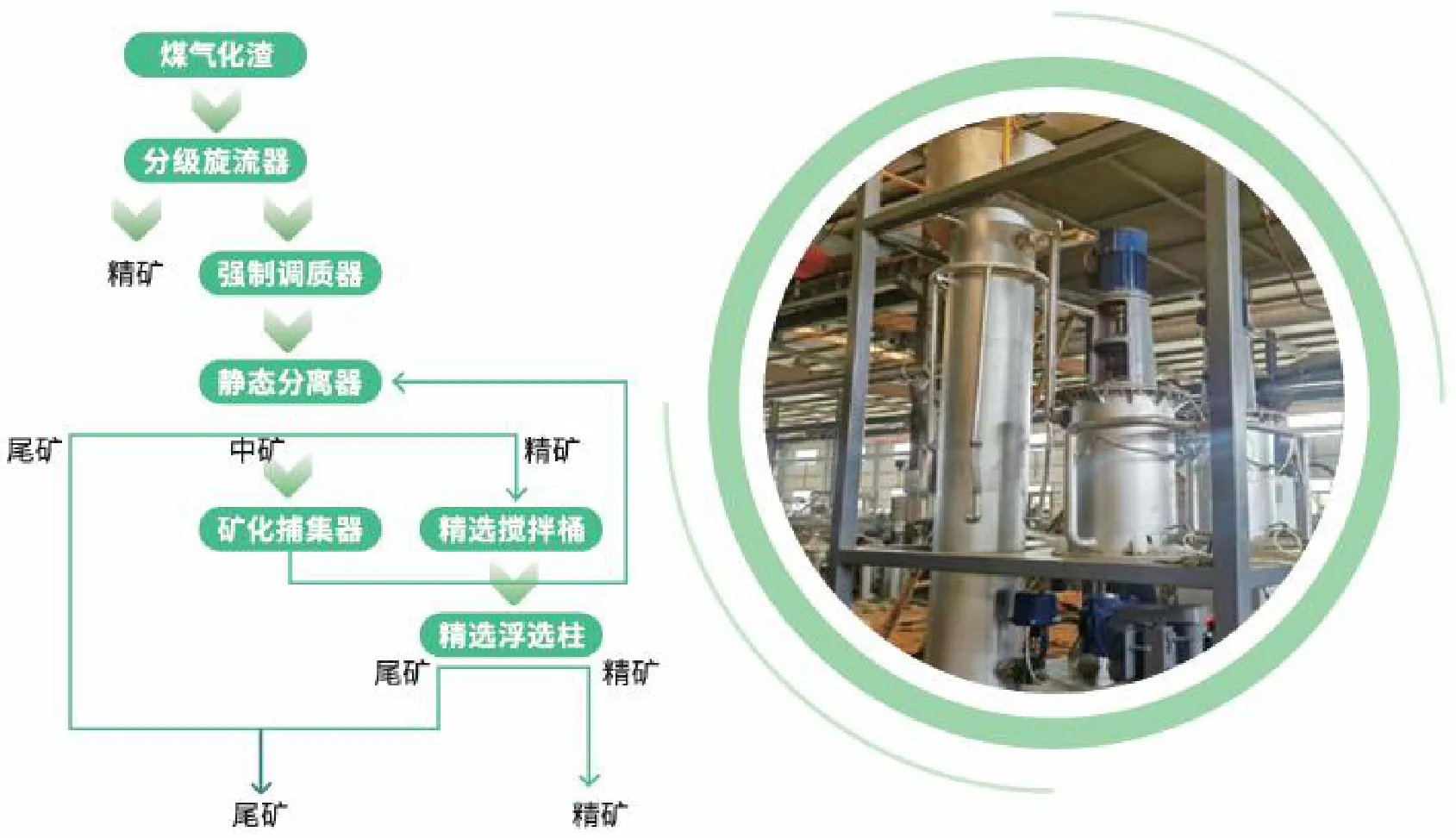

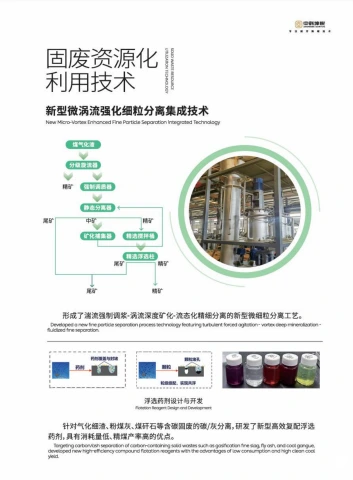

新型微涡流强化细粒分离集成技术

NewMicro-Vortex Enhanced Fine Particle Separation Integrated Technology

形成了瑞流强制调浆-涡流深度矿化-流态化精细分离的新型微细粒分离工艺。

Develpedanewfneparticleseparationprocesstechnolgyfeaturingturbulentforcedagitatin-vortexdeepmineralization fluidized fineseparation.

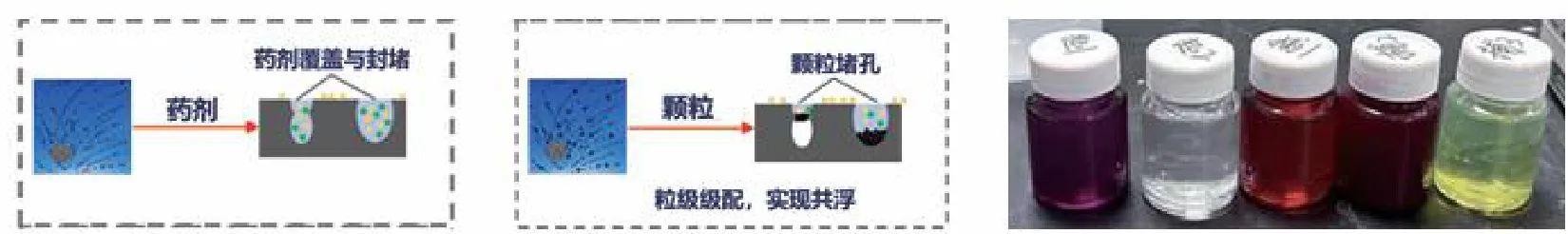

针对气化细渣、粉煤灰、煤研石等含碳固废的碳/灰分离,研发了新型高效复配浮选药剂,具有消耗量低、精煤产率高的优点。

Targetingcarbon/asheparationfcarboncontainingolidastessuchasgasifcationfineslagflyashandcoalgng developed newhigh-efficiency compound flotationreagents with the advantagesof lowconsumptionand highcleancoal yield.

固废资源化利用技术

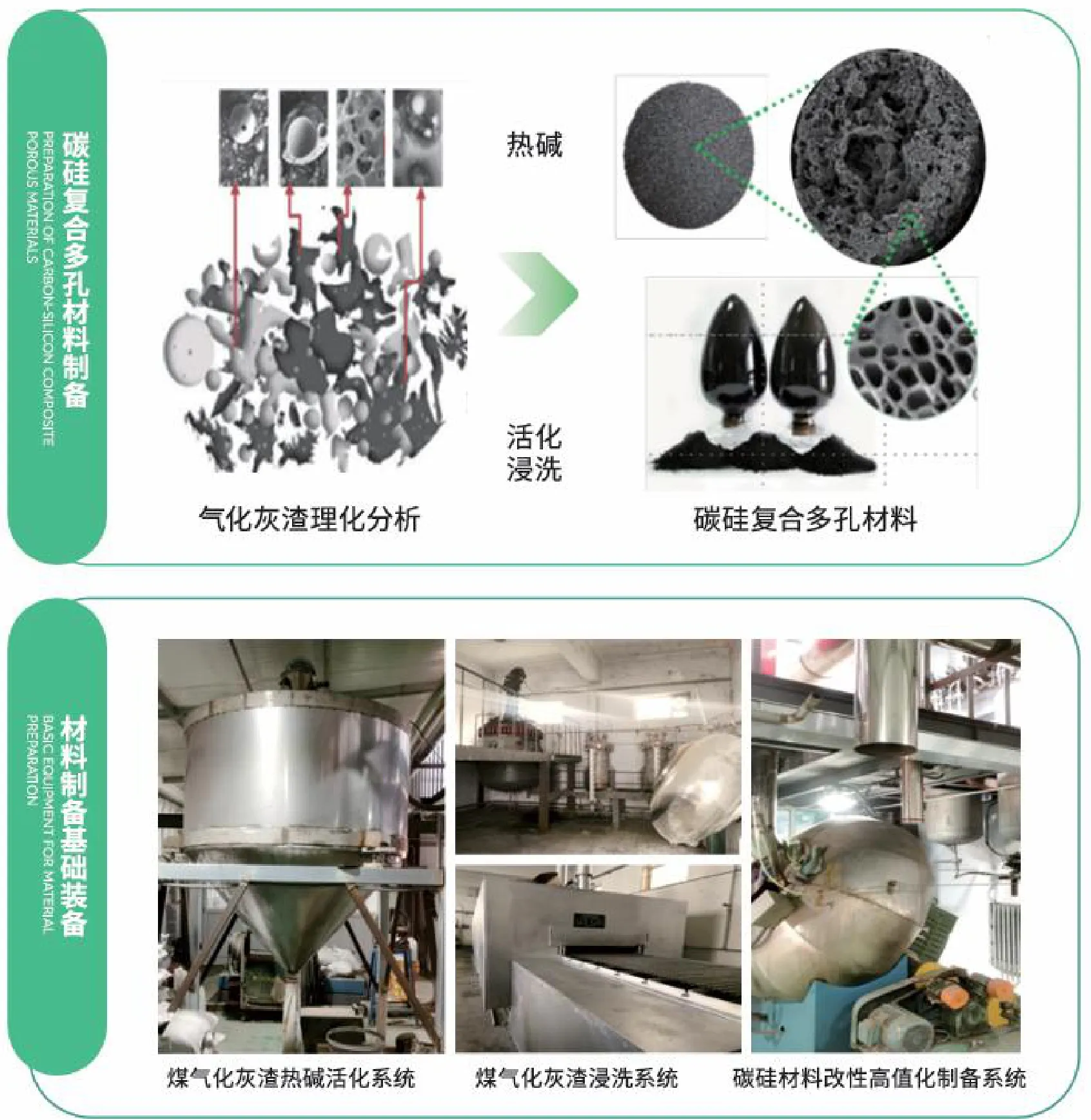

固废基碳硅复合材料制备

PreparationofSolid Waste-Based Carbon-SiliconComposite Materials

利废源化 UTILIZATION TECHNOLOGY SOLID WASTE RESOURCE

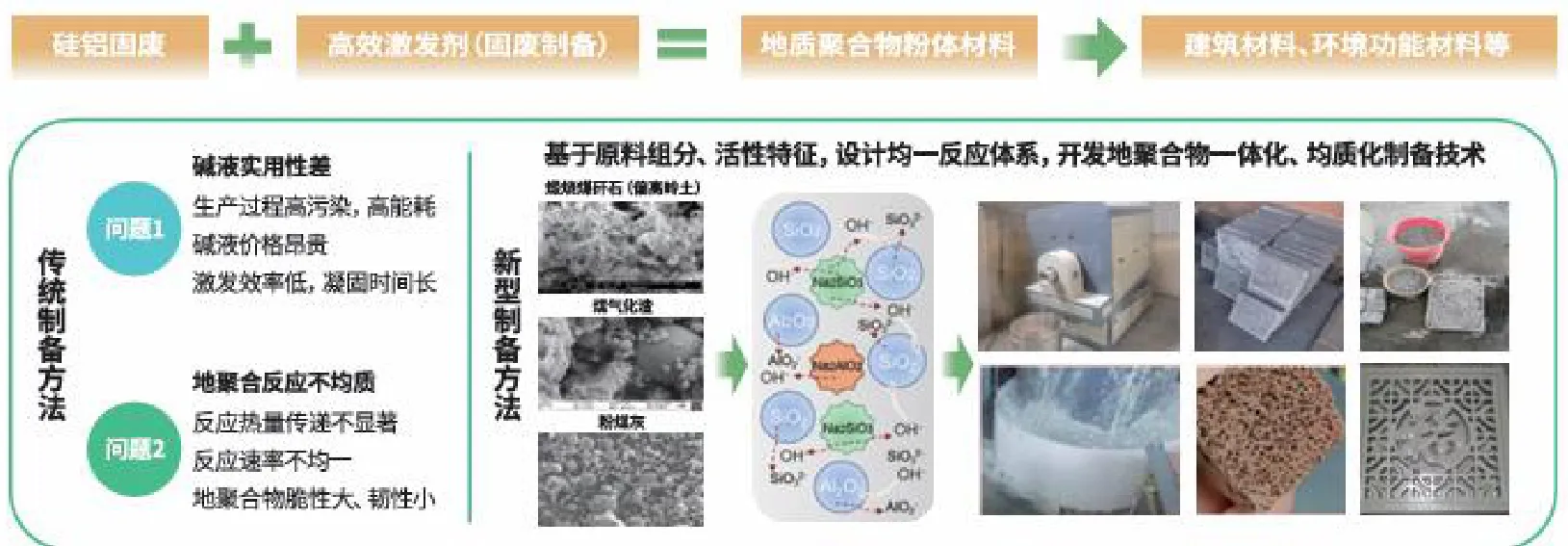

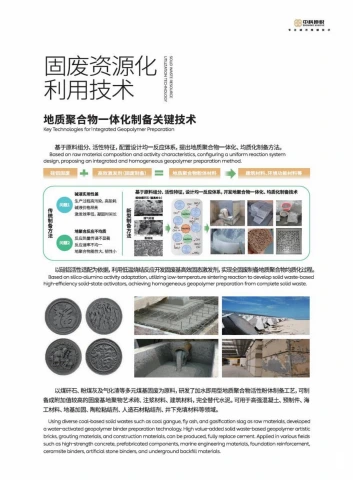

地质聚合物一体化制备关键技术

KeyTechnologiesforlntegrated GeopolymerPreparation

基于原料组分、活性特征,配置设计均一反应体系,提出地质聚合物一体化、均质化制备方法。 Based onrawmaterial composition and activity characteristics,configuring a uniformreaction system design,proposing an integrated and homogeneousgeopolymerpreparation method.

以硅铝活性适配为依据,利用低温烧结反应开发固废基高效固态激发剂,实现全固废制备地质聚合物均质化过程。 Based on silicc-alumina activity adaptation,utilizing low-temperature sintering reaction to develop solid waste-based high-eficiencysolid-state activators,achievinghomogeneousgeopolymerpreparationfromcompletesolidwaste.

以煤研石、粉煤灰及气化渣等多元煤基固废为原料,研发了加水即用型地质聚合物活性粉体制备工艺,可制备成附加值较高的固废基地聚物艺术砖、注浆材料、建筑材料,完全替代水泥。可用于高强混凝土、预制件、海工材料、地基加固、陶粒粘结剂、人造石材粘结剂、井下充填材料等领域。

Using diverse coal-based solid wastes such as coal gangue fly ash, and gasification slag as rawmaterials, developed a water-activated geopolymerbinderpreparation technology.Highvalue-addedsolid waste-basedgeopolymerartistic bricks,grouting materials,and constructionmaterialscanbe produced,fullyreplace cementApplied invarious felds suchashigh-strengthconcrete,prefabricatedcomponents,marine engineeringmaterials,foundationreinforcement. ceramsitebinders,artihicial stonebinders,ond underground backhill materials.

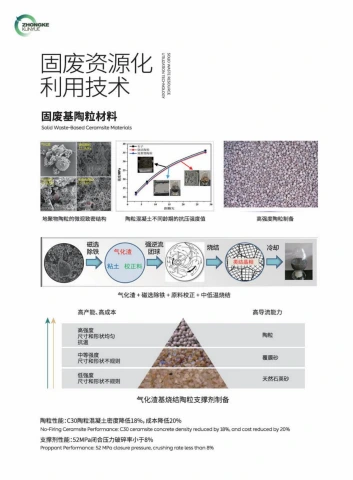

固废资源化利用技术

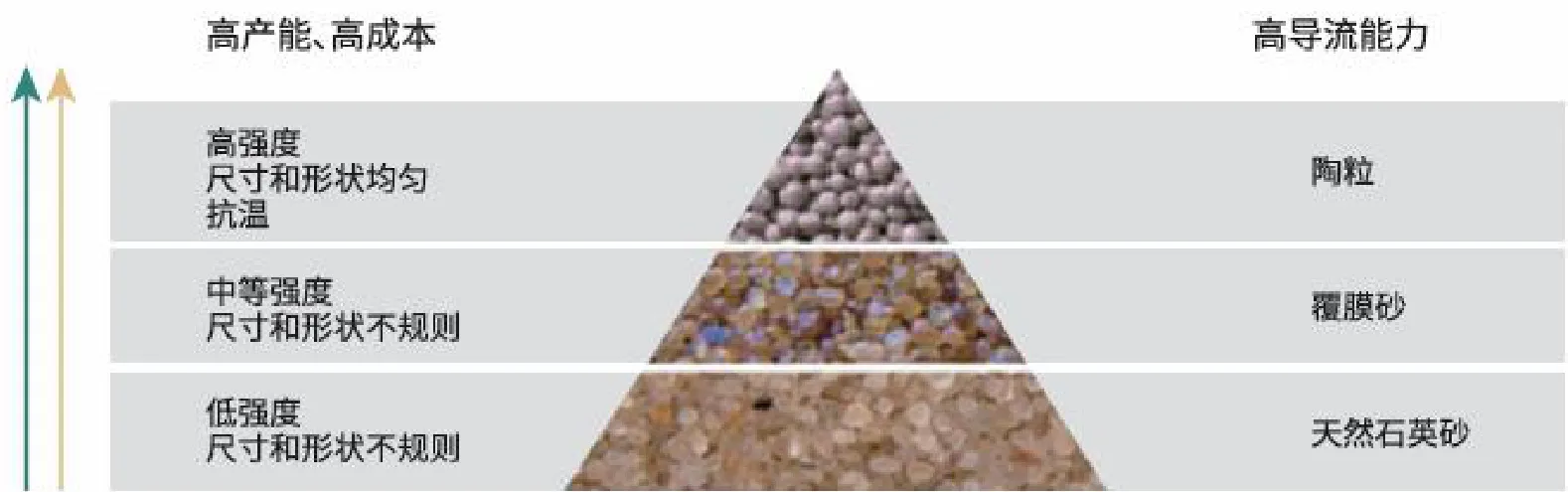

固废基陶粒材料

SolidWaste-Based CeramsiteMaterials

陶粒性能:C30陶粒混凝土密度降低 18% 成本降低 20%

固废资源化利用技术

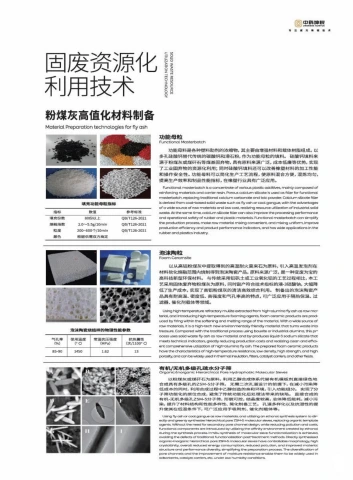

粉煤灰高值化材料制备

MaterialPreparation technologiesforflyash

| 指标 | 数值 | 参考标准 |

| 填充份数 | 80份以上 | QB/T126-2021 |

| 熔融指数 | 2.0~5.5p/10min | QB/T126-2021 |

| 粒度 | 200-600-个/10mln | QB/T126-2021 |

| 颜色 | 根据供蓄双方商定 |

功能母粒

Functional Masterbatch

功能母料是客种塑料助剂的浓缩物,其主要由增强材料和载体树脂组成。以多孔硅酸钙替代传统的碳酸钙和滑石粉,作为功能母粒的填料。硅酸钙填料来源于粉煤灰或煤研石等煤基固弃物,具有原料来源广泛,成本低廉等优势,实现了工业固弃物的资源化利用;同时硅酸钙填料还可以改善橡塑材料的加工性能和操作安全性。功能母料可以简化生产工艺流程,使原料混合方便,混炼均匀,提高生产效率和制品性能指标,在橡塑行业具有广泛应用。

Functional masterbatch is a concentrate of various plostic additives, mainly composed of reinforcing moteriols ond camier resin. Porous colcium siucote is used os fiuer for functionat masterbotch, replacing troditional calcium carbonate and tolc powder. Calcium silicate filer is derived from coal-based solid woste such as fly csh or cool gongue, with the advantoges of a wide source of raw materiois and low cost, realizing resource utRlizatlon of industriol sold waste At the same time, calcium silicate filler can also improve the processing perfonmance and operationol sofety of rubber and plostic moteriails. Functionol masterbatch can slmplify the production process, make row material mbing corvenient, and mbdng uniform, improve production efficency ond product performance indcotors, and has wide applications in the rubber-and plostics industry.

| 气孔率 (96) | 使用温度 | 常温抗压强度 (MPa) | 抗热写性 次/1100- |

| 06-59 | 1450 | 1.62 | 13 |

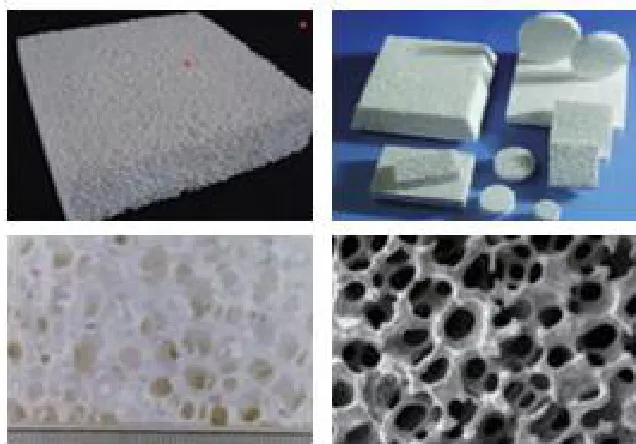

泡沫陶粒

以从高铝粉煤灰中提取得到的高温耐火莫来石为原料,引入高温发泡剂在材料软化熔融范围内烧制得到泡沫陶瓷产品,原料来源广泛,是一种变废为宝的高科技新型环保材料。与传统来用铝矾土或工业氧化铝的工艺过程相比,本工艺采用固体废弃物粉煤灰为原料,同时副产符合技术指标的液-3硅酸钠,大幅降低了生产成本,实现了高铝粉煤灰的清洁高效综合利用。制备出的泡沫陶瓷产品具有耐高温、密度低、高强度和气孔率高的特点,可广泛应用于阴热保温、过滤器、催化剂载体等领域。

Using high-temperature refractory mulite extracted from highnalumina fly ash as rewmoteriaL and inbroducing high-temperoture foaming agents, foam ceramic products are produced by fring within the softening and melting ronge of the materloL With a wide source ot rowmaterials, it is a high-tech new environmentoly friendly material that tums woste into treosure. Compared with the troditional process using baucdte or industriol alumina, this process uses solid waste fty ash as rawmoterial and by-produces liqulc-3 sodlum sllcate thot meets technical indicators. greotly reducing production costs and realizing clean and efficent comprehensive utilization of highralumina fly ash. Tne prepared foam ceramic products hove the charocteristics of nigh-temperature reskstance, low density. high strength, and high porosity. and con be widety used in thermal insulation, fiters. cotolyst carriers, and other fields.

有机无机多级孔琉水分子筛Grnnnic/nrmnnir Hemrhirnl Pnre H

以粉提灰或煤研石为原料,利用乙醇合成体系代普有机模板剂直接绿色地音成具有多级孔的ZSM-5分子筛。无需二次孔道设计的前提下,在减小污染降低成本的同时,利用合成过程中之醇创造的亲和环境,引入功能组分。实现了分子筛功能化的原位合成,避免了传统功能化后处理法带来的缺陷。直接合成的有机-无机多级孔ZSM-5分子蹄,形貌可控,结品度较高,总体降低能耗,减小污染,提升了材料结构和性能多样性、简化制毒工艺。孔道多样化以及抗湿性的提升使其在低湿条件下,可广泛应用于吸附剂、他化剂载体等。

Using fy ash er coal gangue as rawmateriols. and utilizing an ethonol synthesis system to dir ectly and greenly synthesize hlerarchlcol pore ZsM-5 molecular sleves, replocing orgonic templote ogents. without the need for secondary pore channel design. while reducing pollution and costs. functional components are introduced by utlizing the afhnity ervironment created by ethanol during the synthesisprocess.In-situ synthesis of molecular sieve functionolization is achieved, avokding the defects of trodtionol functionalization post-trectnent methods Directly symthestzed orgonic-norganic hieronchiooL pore ZsM-5 moleculor sicves hove controllable morphology. high crystallnity.overall reduced energy consurmption,reduced pollution,and irnproved material structure and performance diversity. sipuirying the preparortion process. The diversihcotion of pore channets and the irmprovement of moisture resistance enoble them to be widely used in odsorbents, cotolyst camers,etc. under low humidity conoitons.

废源化 JTILZATIONTECHNOLOGY

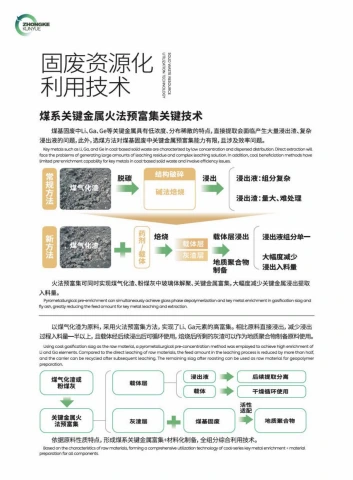

煤系关键金属火法预富集关键技术

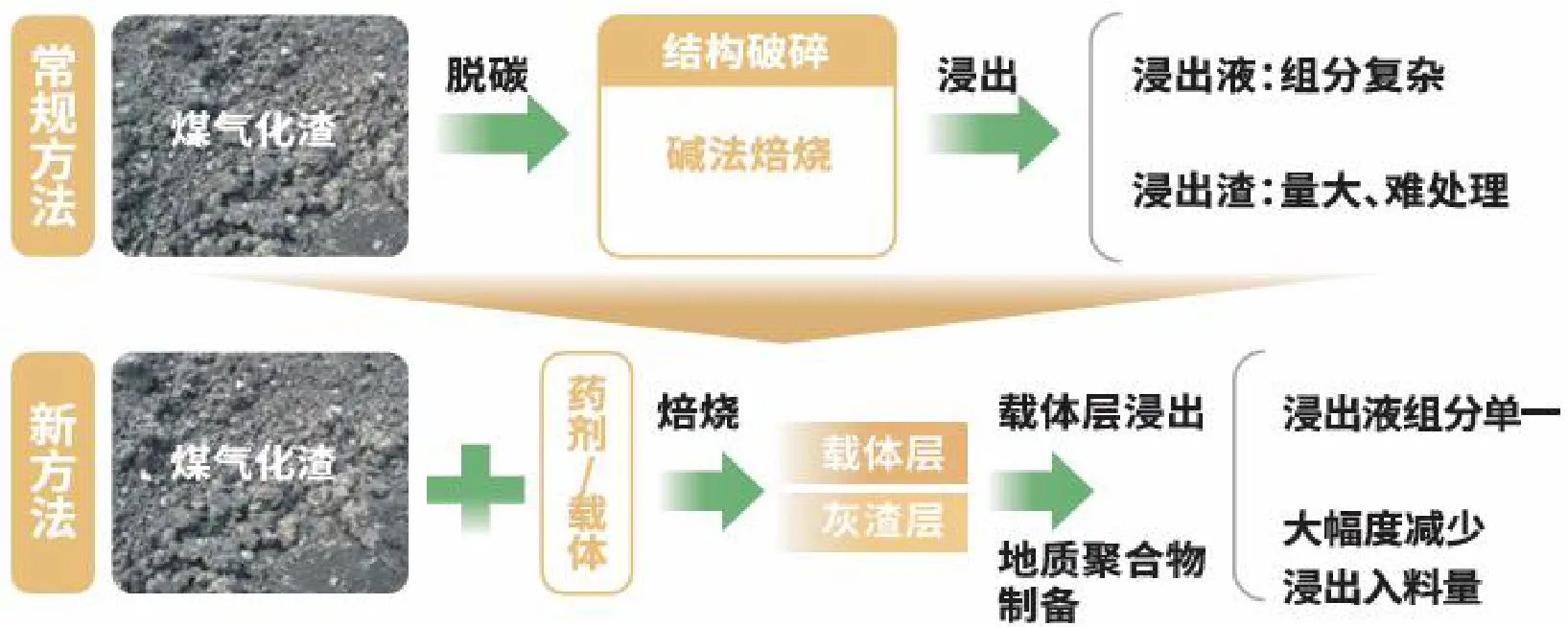

煤基固废中Li、Ga、Ge等关键金属具有低浓度、分布稀散的特点,直接提取会面临产生大量浸出渣、复杂浸出液的问题,此外,选煤方法对煤基固废中关键金属预富集能力有限,且涉及效率问题。

Key metals such os Li, Ga, and Ge in cool-based solld waste cre charocterized by low concentratlon and dispersed distrlbution. Direct extraction will face the prablems of generating large amounts of leaching residue and complex leaching solution.In addition,coal beneficiationmethodis have limited pre-enrichment capobility for key metols incoal-based solid waste ond involve efficiency issues.

火法预富集可同时实现煤气化渣、粉煤灰中玻璃体解聚、关键金属富集,大幅度减少关键金属浸出提取入料量。

以煤气化渣为原料,采用火法预富集方法,实现了Li、Ga元素的高富集。相比原料直接浸出,减少浸出过程入料量一半以上,且载体经后续浸出后可循环使用,培烧后所剩的灰渣可以作为地质聚合物制备原料使用。

Using coal gasification slog as the raw materiol, a pyrometallurgical pre-concentration method was employed to ochleve high enrichment of Li and Ga elements. Compared to the direct leaching of rawmaterials, the feed amount in the leaching processis reduced by more than half, and the carrer can be recycled after subsequent Leaching. The remaining slog after roasting can be used as rawmaterial for geopolymer preparotion.

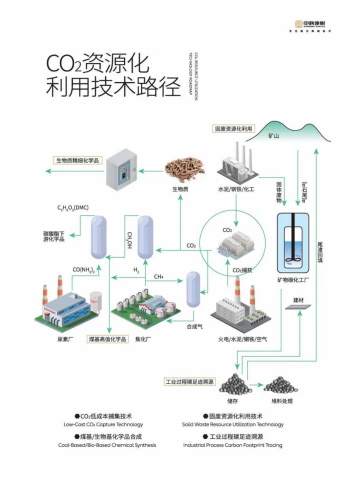

TECHNOLOGY ROADMAP CO:RESOURCE UTIUZATION

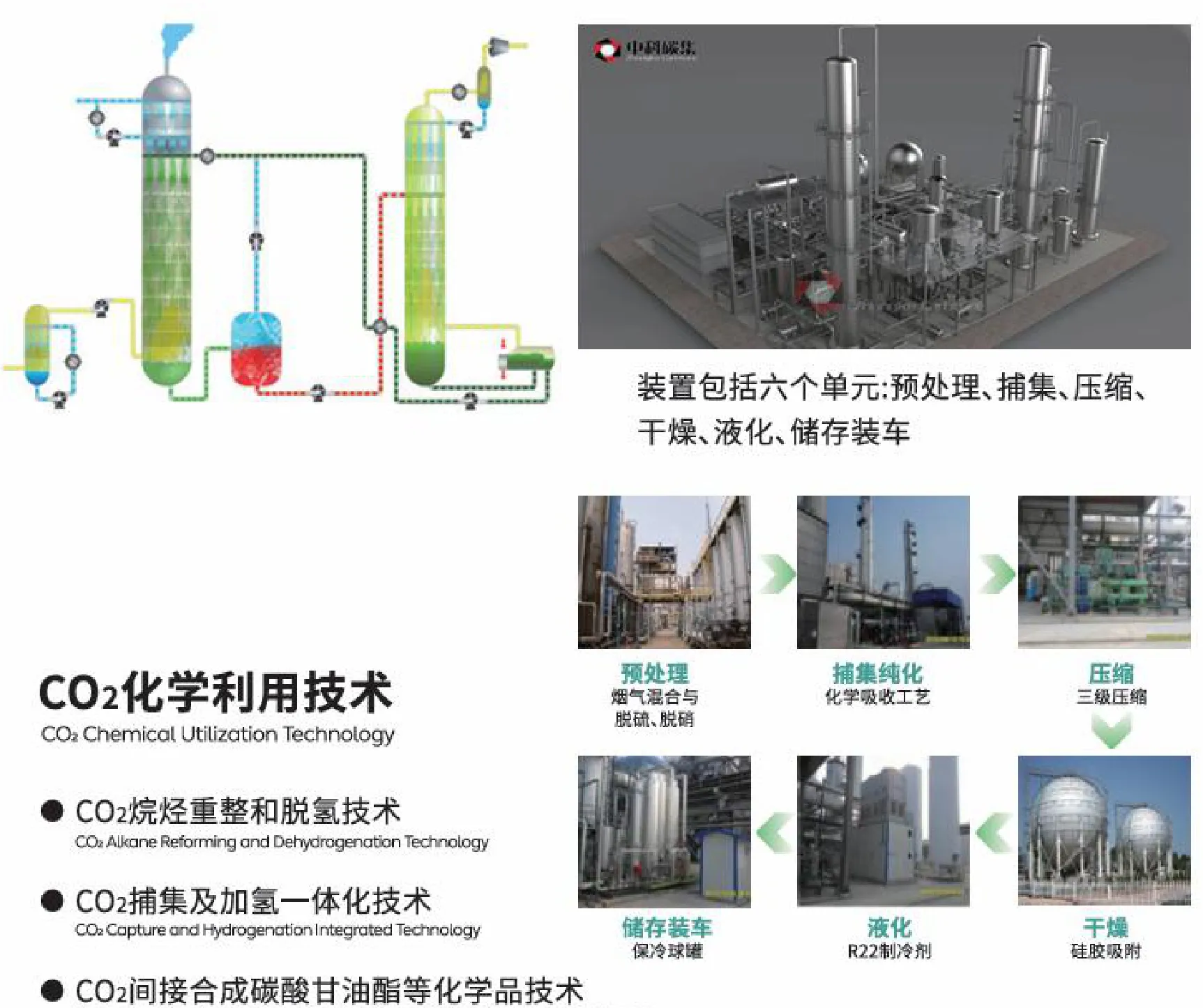

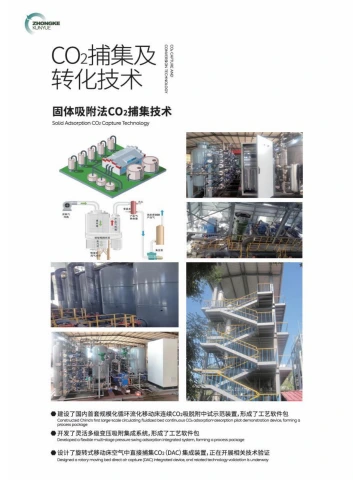

CO2捕集及转化技术

固体吸附法CO2捕集技术

Solid AdsorptionCO2CaptureTechnology

●开发了灵活多级变压吸附集成系统,形成了工艺软件包Developedflexiblemult-stoge pressureswingadsorptininterated systemfoming processockage

设计了旋转式移动床空气中直接捕集CO2(DAC)集成装置,正在开展相关技术验证 Designedratarymoing bed directaircaptureDAC integrateddeviceand related technologyvalidtionisunderwoy

CO2资源化利用技术

化学吸收法CO2捕集技术

Solid Adsorption CO2 Capture Technology

COsIncirect Synthesis of Glycerol Carbonate and Other Chemical Technologies

研发了捕集过程强化吸收/解析催化剂,大幅降低了CO2捕集能耗,同时开展了CO2制备化学品中试技术验证。

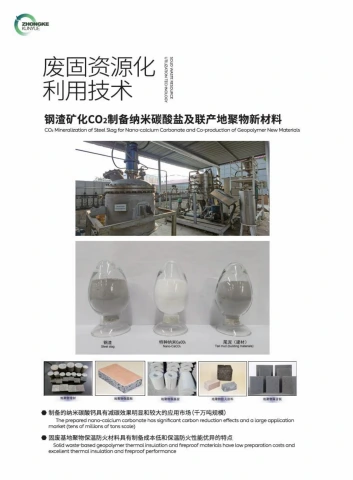

废固资源化利用技术

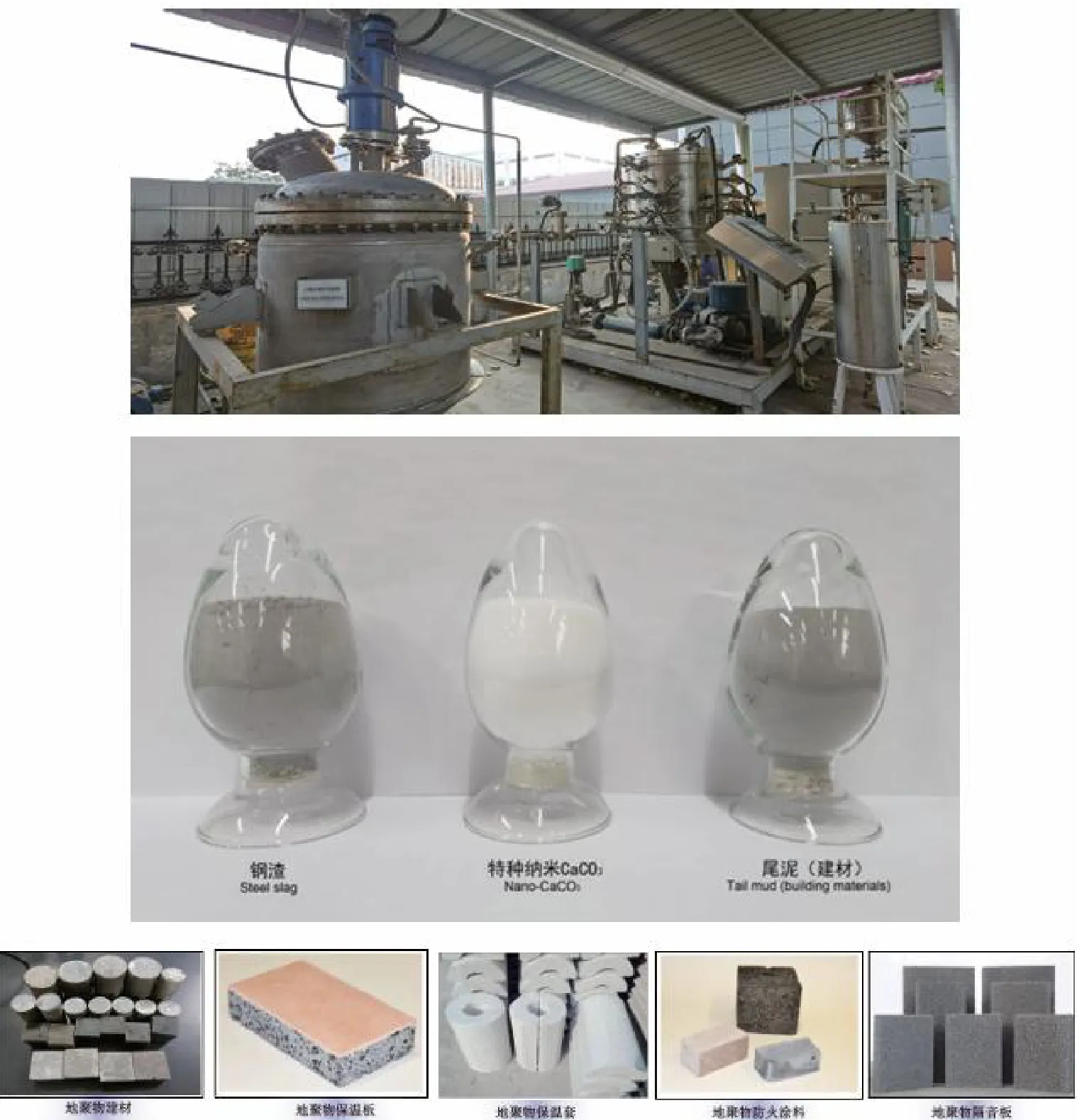

钢渣矿化CO2制备纳米碳酸盐及联产地聚物新材料

制备的纳米碳酸钙具有减碳效果明显和较大的应用市场(千方吨规模)

The preparednano-calciumcarbonate has significantcarbonreduction effects anda large application market (tens of millions of tons scale)

废基地聚物保温防火材料具有制备成本低和保温防火性能优异的

Solid waste-basedgeopolymerthermalinsulation andfreproofmaterialshave lowpreparationcosts and excellent thermalinsulationand freproofperformance

DEMONASTRATION

气化细渣碳灰分离技术示范

CONCAPTURN TECHNOLOGY

CO2捕集及资源化技术示范

形成了十万吨级富钙固废(钢渣、电石渣、脱硫石膏、磷石膏等)矿化CO2制备纳米碳酸盐及联产地聚物新材料的工艺软件包,将为规模化减污降碳提供技术支撑。

A process package for preparing nano-calcium carbonate and co-producing geopolymer new materials from 100,000-ton scale calcium-rich solid waste (steel slag,calcium carbide slag,desulfurization gypsum, phosphogypsum, etc.) through CO2 mineralization has been formed, which will provide technological support for large-scalepollutionreduction andcarbonreduction.

气化灰渣材料化制备示范线

MATERIATPRPARATON ROM DEMONSTRATION LINE FOR

开发了气化灰渣基碳硅复合多孔材料及地聚物新材料宏量制备装置,形成了气化灰渣全消纳的技术路径。

A macro preparation device forcarbon-silicon composite porous materials and geopolymers based on gasification ash and slag was developed, and a technical path for complete consumption of gasiication ashandslagwasformed.

06 合流 COMMERATIANION

中科坤悦(北京)科技有限公司ZHONGKEKUNYUE (Beijing)Technology Co.,Ltd.地址:北京市中关村

中科坤悦(山西)科技有限公司ZHONGKEKUNYUE(Shanxi)Technology Co.,Ltd.地址:晋创谷·太原

电话:13520636667

该页无缩略图

该页无缩略图