高纯度制氮机High purity nitrogen generator

诚信 创新 共赢 发展INTEGRITYINNOVATIONWIN-WINDEVELOPMENT

石家庄德淼科技有限公司专注于各行业氮气机多年,生产主要产品包括:制氮机、工业制氧机、吸附干燥机可为客户量身定制适合的产品。

公司拥有专业技术研发及管理团队,并且一直致力于科技创新,以不断满足广大客户的要求为目标,坚持”质量为本,用户至上”。为客户竭诚服务到永远,是公司的宗旨,坚持以质量求生存,以诚信求发展,以管理求效率,以科研求进步,以服务创品牌的经营理念,是公司的永恒承诺,坚信说得好不如做的好。

产品现已覆盖各地,出口西班牙、墨西哥、尼泊尔、马来西亚等。目前产品已广泛应用于以下领域:石油、化工、冶金、电力、机械、轻工、纺织、汽车维修、电子、食品、热处理、有色金属等行业。公司全体员工热忱欢迎新老客户前来厂区及设备现场参观、考察!

竭诚为您提供专业的制氮解决方案

DEDICATED TOPROVIDE YOUWITHAPROFESSIONALNITROGENSOLUTION

公司全面实施”一站式气体服务”

为每位客户争取在短时间内解决问题

ShijiazhuangDemiaoTechnology Co.,Ltd.hasbeenfocusingonnitrogengenerators invariousindustriesfor manyyears.Itsmainproductsincludenitrogengenerators,industrialoxygenconcentrators,andadsorption dryers,whichcanbecustomizedtomeettheneedsofcustomers.

Thecompanyhasaprofessionaltechnicalresearchanddevelopment andmanagementteam,andhasalways beencommittedtotechnologicalinnovation,withthegoalofcontinuouslymeetingtherequirementsofcustomers and adheringtotheprincipleof"qualityfirst,customerfirst".Servingcustomerswholeheartedlyuntileternityis thecompany'smission.Adheringtothebusinessphilosophyofsurvival throughquality,developmentthrough integrity,efficiencythroughmanagement,progressthroughscientificresearch,andbrandbuildingthrough serviceisthecompany'seternalcommitment.Wefirmlybelievethatdoingwellisbetterthansayingwell.

Theproducthasnowcoveredvariousregionsandisexportedtopain,Mexico,Nepal,Malaysia,andothers. Atpresent,theproductshavebeenwidelyused inthefollowingfields:petroleum,chemical,metallurgicalpower, machinery,lightindustry,textile,automotivemaintenance,electronics,food,heattreatment,non-frrousmetals andotherindustries.Allemployeesof thecompanywarmlywelcomenewandoldcustomerstovisit andinspect thefactoryandequipmentsite!

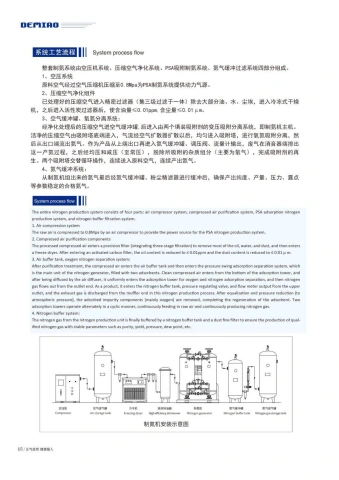

系统工艺流程

Systemprocessflow

整套制氮系统由空压机系统、压缩空气净化系统、PSA吸附制氮系统、氮气缓冲过滤系统四部分组成。

1、空压系统

原料空气经过空气压缩机压缩至0.8Mpa为PSA制氮系统提供动力气源。

2、压缩空气净化组件

已处理好的压缩空气进入精密过滤器(集三级过滤于一体)除去大部分油、水、尘埃,进入冷冻式干燥机,之后进入活性炭过滤器后,使含油量 <=slant0. 01ppm,含尘量 <=slant0.01\sharp m

3、空气缓冲罐、氧氮分离系统:

经净化处理后的压缩空气进空气缓冲罐,后进入由两个填装吸附剂的变压吸附分离系统,即制氮机主机。洁净的压缩空气由吸附塔底端进入,气流经空气扩散器扩散以后,均匀进入吸附塔,进行氧氮吸附分离,然后从出口端流出氮气。作为产品从上端出口再进入氮气缓冲罐、调压阀、流量计输出,废气在消音器端排出这一产氮过程,之后经均压和减压(至常压),脱除所吸附的杂质组分(主要为氧气),完成吸附剂的再生。两个吸附塔交替循环操作,连续送入原料空气,连续产出氮气。

4、氮气缓冲系统:

从制氮机组出来的氮气最后经氮气缓冲罐、粉尘精滤器进行缓冲后,确保产出纯度、产量、压力、露点等参数稳定的合格氮气。

Systemprocessflow

Theentirenitrogenproductionsystemconsistsffourpartsaircompressorsystemcompresedairpurificationsystemadsorptionnitrogen productionsystem,andnitrogenbufferfitrationsystem.

1.Aircompression system

Therawairiscompressedto0.8MpabyanaircompressortoprovidethepowersourceforthePSAnitrogenproductionsystem.

2.Compressed air purificationcomponents

Theprocessedcompressedairentersaprecisionfilter(integratingthree-stagefiltration)toremovemostoftheoilwater,anddustandthenenters afreezedryer.Afterenteringanactivatedcarbonfilter,theoilcontentisreducedto≤0.01ppmandthedustcontentisreducedto <=0.01 \upmu \mathsf{m} 3.Airbuffertank,oxygennitrogenseparationsystem:

Afterpurificationtreatment,thecompressedairenterstheairbuffertankandthenentersthepressureswingadsorptionseparationsystem,which isthemainunitof thenitrogengenerator,filledwithtwoadsorbents.Cleancompressedairentersfromthebottomof theadsorptiontower,and afterbeingdiffusedbytheairdiffuser,ituniformlyenterstheadsorptiontowerforoxygenandnitrogenadsorptionseparation,andthennitrogen gasflowsoutfromtheoutletend.Asaproduct,itentersthenitrogenbuffertank,pressureregulatingvalve,andflowmeteroutputfromtheupper outlet,andtheexhaustgasisdischargedfromthemufflerendinthisnitrogenproductionprocess.Afterequalizationandpressurereduction(to atmosphericpressure),theadsorbedimpuritycomponents(mainlyoxygen)areremoved,completingtheregenerationoftheadsorbent.Two adsorptiontowersoperatealternatelyinacyclicmanner,continuouslyfeedinginrawairandcontinuouslyproducingnitrogengas.

Thenitrogengasfromthenitrogenproductionunitisfinallybufferedbyanitrogenbuffertankandadustfinefitertoensuretheproductionofqualifiednitrogengaswithstableparameterssuchaspurity,yieldpressure,dewointet.

德森制氮优点

传统的取氮的方法是液化空气,然后在-180℃左右的温度下进行蒸馏。工艺过程非常复杂,制氮的总成本很高。PSA制氮机可在正常大气下运行,其优点如下:

(1)低生产环境。

(2)工艺简单,设备少,自动化程度高,操作方便。

(3)快速启动,易于停止。该系统可以在启动后30分钟内提供产品气体,也可以间歇性操作。

(4)工作压力低,工作安全,无毒无害无污染。

(5)良好的灵活性。氮气的纯度和输出量可以很容易地调整。

AdvantagesofDemiaoNitrogenProduction

Thetraditionamethodofnitrogenextractionistoliquefyairandthendistillitatatemperatureofaround-18C.Theprocessisverycomplexandthetota costofnitrogenproductionishighhePSAnitrogengeneratrcanoperateundernormalatmosphericconditionsanditadvantagesareasfollow (1)Lowproductionenvironment.

(2)Theprocessissimple,theequipment isfew,thedegreeofautomationishigh,andtheoperationisconvenient.

(3)Quickstartandeasytostop.Thesystemcanprovideproductgaswithin30minutesof startuporoperateintermittently.

(4)Lowworkpressure,safework,non-toxic,harmlessandpollution-free.

(5)Goodflexibility.Thepurity andoutputof nitrogencanbeeasilyadjusted.

制氮机适用领域

完全可替代市场各类型瓶装氮气

1、食品充氮保鲜包装、蔬菜水果保鲜、酒类封装、粮食绿色仓储等。

2、防爆型制氮机适用于化工、石油天然气等对设备有防爆要求的场所。

3、电子行业适用于半导体生产封装、电子元器件生产(SMT)、LED、LCD液晶显示器、锂电池 生产等领域。

4、冶金行业专用制氮机适用于热处理、光亮退火、保护加热、粉末冶金、铜材铝材加工、磁 性材料烧结、贵金属加工、轴承生产等领域。

5、化工行业专用制氮机适用于石油化工、煤化工、盐化工、天然气化工、精细化工、新材料 等及其行伸化工产品加工行业等领域。

6、激光切割焊接、环保设备配套、汽车检测设备配套等领域。

1.Foodnitrogenfilledpreservationpackaging,vegetableandfruitreservation,alcoholpackaging,greengrainstorage,etc.

2.Explosionproofnitrogengeneratorsaresuitableforplaceswithexplosion-roofrequirementssuchaschemicalpetroleumand naturalgasindustries.

3.Theelectronicsindustryissuitableforsemiconductorproductionpackaging,electroniccomponentmanufacturing(SMT),LED, LCDliquidcrystaldisplay,lithiumbatteryproduction andotherfields.

4.Thespecializednitrogengeneratorforthemetallurgicalindustryissuitableforfelssuchasheattreatmentbrightanealing, protectiveheatingowdermetallurgycopperandaluminumprocessingmagneticmaterialsinteringreciousmet processing,andbearingproduction.

5.Thespecializednitrogengeneratorforthechemicalindustryissuitableforfieldssuchaspetrochemicals,coalchemicals,salt chemicals,naturalgaschemicals,finechemicals,newmaterials,andtheirderivativechemicalproductprocessingindustries.

6.Fieldssuchaslasercuttingandwelding,environmentalprotectionequipmentmatching,andautomotivetestingequipment

激光焊接专用制氮机

Laserwelding dedicated nitrogengenerator

激光焊接制氮机

Laserwelding nitrogengenerator

在焊接领域,氮气的主要作用是排除焊接过程中的氧气,增加可焊性,防止再氧化。可靠优质的焊接除了需要合适的焊料,还需要焊剂的配合。焊剂的作用主要是去除焊接前焊接部位的氧化物以及防止焊接部位的再氧化,并形成焊料优良的润湿条件,提高可焊性。氮气已成为激光焊接中最为常用和最为重要的反应气体之一。

Inthefieldofweldingthemainfunctionofnitrogenistoelminateoxygenduringtheweldingprocessincreasewedabilityandpreventreoxida tion.Reliableandhigh-qualityweldingrequiresnotonlysuitablesolder,butalsothecoordinationofflux.Themainfunctionofsolderfluxisto removeoxidesfromtheweldingareabeforeweldingpreventreoxidationof theweldingareaandcreateexcellentwetingconditionsforthe solder,therebyimprovingweldability.Nitrogenhasbecomeoneof themostcommonlyusedandimportantreactivegasesinlaserwelding.

氮气-激光焊接机的保护气体

Laserweldingnitrogengenerator

1、保护聚焦透镜免受金属蒸气污染和液体熔滴的溅射

2、保护气体对驱散高功率激光焊接产生的等离子屏蔽很有效

3、保护气体可使工件在焊接过程中免受氧化

1.Protectthefocusinglensfrommetalvaporcontaminationandsplashingof liquiddroplets

2.Theprotectivegasisveryeffectiveindissipatingtheplasmashieldinggeneratedbyhigh-powerlaserwelding

3.Protectivegascanprotecttheworkpiecefromoxidationduringtheweldingprocess

灵活小巧移动方便

Flexible,compact,andeasytomove

不会影响激光传输直接到达工件表面

Itwillnotaffectthedirecttransmissionoflasertothesurfaceoftheworkpiece

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 0.8Nm3/h | 99.99% | 230x680x830 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、氮气过滤装置、 优质气动元件。 Nitrogen detector,molecularsieve(CMS),oilwaterseparation device,Nitrogen filtration device | ||||

| 工作原理 Workingprinciple | high-qualitypneumaticcomponents. PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogenproduction | ||||

氮气出口升级新增限压阀、双出口流量计

_Nitrogenexportupgradewithaddedpressurelimitingvalveanddualoutletflowmeter

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogenpressure | 露点 The dew point |

| 1Nm3/h | 99.99% | 520x450x1270 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、氮气过滤装置、 优质气动元件。 Nitrogen detector, molecular sieve (CMS), oil-water separation device,Nitrogen filtration device, | ||||

| 工作原理 Workingprinciple | high-qualitypneumaticcomponents. PSA变压吸附物理制氮 PSApressureswing adsorptionphysicalnitrogenproduction | ||||

设备结构紧凑、内置冷干机、40L储气罐

Compactequipmentstructurebuilt-inrefrigerateddryer0Lairstragetank

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogenpressure | 露点 The dew point |

| 1Nm3/h | 99.99% | 650x830x1270 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、氮气过滤装置、 优质气动元件、冷干机、40L储气罐。 Nitrogen detector, molecular sieve (CMS), oil-water separation device,Nitrogen filtration device, high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysicalnitrogenproduction | ||||

高节能易操作

激光焊接专用制氮机

—Highenergy-savingandeasytooperateLaserweldingdedicatednitrogengenerator

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Airpressure | 氮气压力 Nitrogenpressure | 露点 The dew point |

| 2Nm²/h | 99.99% | 620x560x1380 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、氮气过滤装置 优质气动元件。 Nitrogen detector,molecular sieve (CMS),oil-water separation device,Nitrogen filtration device, | ||||

| 工作原理 Working principle | high-qualitypneumaticcomponents. PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogenproduction | ||||

箱体式制氮机

Box typenitrogengenerator

高效快捷开机即可制取氮气

Eficientandfaststartutproducenitrgngas

氮气在商业食品和饮料制造中的使用已经彻底改变了食品保存。由于其情性的化学特性,气态氮可以减缓导致食品变质的氧化过程。常用于饮料行业、食品加工、食品包装和存储。

Theuseof nitrogenincommercialfoodandbeveragemanufacturinghascompletelychanged foodpreservation.Duetoitsinertchemicalproperties,gaseousnitrogencanslowdowntheoxidationprocessthatcausesfoodspoilage.Commonlyused inthebeverageindustry,foodprocessing,foodpackaging,andstorage.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 1.5Nm²/h | %66 | 500x430x1300 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃-20℃ |

| 1.2Nm3/h | 99.5% | ||||

| 1Nm²/h | 99.9% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、氮气过滤装置、 优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,Nitrogen filtration device | ||||

| 工作原理 Working principle | high-quality pneumaticcomponents. PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogenproduction | ||||

操作简单性能稳定

Simpleoperationandstableperformance

设备结构紧凑、整体内置,占地小无需基建投资,投资少;先进的技术,独特的气流分布器,使气流分布均匀有效地利用,开机即可生产合格的氮气

Theequpmenthasacompactstructureiinteratedasawhole,occupiesasmallarea,des notrequireinfrastructureinvestment,and haslowinvestment;Advanced technologyand uniqueairflowdistributorenableevenandeffectiveutilizationofairflowdistribution,andqualifiednitrogencanbeproduced immediatelyuponstartup

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 2.5Nm²/h | 99.5% | 520x450x1270 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 2Nm²/h | 99.9% | ||||

| 1Nm²/h | 99.99% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、氮气过滤装置、 优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,Nitrogenfiltration device high-qualitypneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

自动化运行

Automatedoperation

进口PLC控制全自动运行,氮气流量压力纯度可调并连续显示,可实现无人值守。

ImportedCcontrolsfullyautmaticperationwithadjustablenitrogenflowrateressureand purity,andcontinuousdisplay,enablingunmannedoperation.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 5Nm3/h | 99% | 620x560x1380 | 0.65-0.8Mpa | 0.1-0.7Mpa | |

| 3Nm²/h | 99.9% | -40℃~-20℃ | |||

| 2Nm3/h | 99.99% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecular sieve(CMS),oil-waterseparationdevice,PLCcontrol system Nitrogen filtration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

高品质设备元件

Highqualityequipment components

为保证PSA制氮主机的长期、稳定正常运转,压缩空气在进入制氮机前必须进行除尘、除水、除油等净化处理,以达到制氮机对压缩空气品质的要求。我们的主要部件如分子筛、阀门、控制器等均采用原装进口的知名品牌的产品。以保证整套系统的设备质量和安全、长期、可靠运行。

Toensurethelong-term,stableandnormaloperationofthePSAnitrogengeneratorcompressedaimustundergopurificationtreatmentsuchasdustemovalwaterremovalandil removalbeforeenteringthenitrogengeneratortomeettherequirementsof thenitrogengeneratorforcompressedairquality.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 5Nm/h | 99.9% | 620x560x1630 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 3Nm²/h | 99.99% | ||||

| 2Nm3/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecularsieve(CMS),oil-waterseparationdevice,PLCcontrol system Nitrogen filtration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

专注制氮设备

Focus on nitrogenproductionequipment

微电脑控制,全自动操作,只需按下启动开关,就可自动运转,达到连续生产氮气。

氮气纯度稳定,都由仪器监控和显示,确保所需氮气纯度。

Microcomputercontrol,fullyautomaticoperation,noneedforspeciallytrainedoperatorsjust pressthestartswitchto automaticallyoperate,achievingcontinuousproductionofnitrogen gas.Thenitrogenpurityisstableandmonitored anddisplayedbyinstrumentstoensurethe requirednitrogenpurity.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 6Nm²/h | 99.9% | 900x700x1500 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 5Nm3/h | 99.99% | ||||

| 3Nm²/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device,high-qualitypneumaticcomponents. | ||||

| 工作原理 Workingprinciple | PSA变压吸附物理制氮 PSApressure swing adsorption physical nitrogenproduction | ||||

智能化的控制面板

Intelligent controlpanel

氮气流量压力纯度可调并连续显示,先进的控制系统使操作变得更加简单,从而保证了气体纯度、流量的稳定。

Thenitrogenfowrateressureandpuritycanbeadjustedandcontinuouldiplayedh advancedcontrolsystemmakestheoperationsimplerensuringthestabilityofgaspurityand flowrate.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 10Nm3/h | 99.9% | 1000x750x1600 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 8Nm²/h | 99.99% | ||||

| 5Nm²/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecularsieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device, high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

内置一体式制氮机

Builtinintegratednitrogengenerator

制氮机内置空压机、冷干机、氮气罐,安装使用更方便。

Thenitrogengneratorisequppedwithanaircomressorrefrigerateddyerandanitrogn tank,makinginstallationandusemoreconvenient.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 15Nm3/h | 99.9% | 1150x1100x1700 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 10Nm3/h | 99.99% | ||||

| 7Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件、冷干机、储气罐。 Nitrogendetector,molecular sieve(CMS),oil-water separationdevice,PLCcontrol system Nitrogenfiltration device,high-qualitypneumaticcomponentsCold dryer,air storage tank | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogenproduction | ||||

外置撬装组合制氮机

Externalmodularnitrogengenerator

只需干燥压缩空气的供应。即插即用,不需要特别安装和调试。便于维修保养

Justneedasuplyofrycmpresedairlugandplayoedfrpecianstallationnd debugging.Easytomaintainandrepair

| 氮气流量 Nitrogenflow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 5Nm3/h | 99.9% | 1200x650x1700 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 3Nm3/h | 99.99% | ||||

| 2Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件、冷干机、储气罐。 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogenfiltrationdevice,high-qualitypneumaticcomponents,Colddryer,air storage tank | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogenproduction | ||||

外置式制氮机

Externalnitrogengenerator

质量可靠氮气纯度高

Reliablequalityandhighpurityfnitrogengas

严选优质配件,运行可靠,切换速度快,使用寿命达百万次以上,故障率低,维修方便,维护费用低。

Caeulltiqultssriialatnastihnervi ofovernemilliontmeslowfailurerateeasymaintenance,andlowmaintenancecosts.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 6Nm3/h | 99.9% | 950x750x1550 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 5Nm²/h | 99.99% | ||||

| 3Nm²/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogendetector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device, high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

氮气纯度稳定

Stablepurity of nitrogen

氮气含量连续显示、超限自动报警系统:在线监控氮气纯度,确保所需氮气纯度稳定。

Continuous displayof nitrogen content and automaticalarm systemforexceedinglimits:online monitoringof nitrogenpuritytoensurestablerequirednitrogenpurity.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 10Nm3/h | 99.9% | 1000x800x1550 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 8Nm3/h | 99.99% | ||||

| 5Nm3/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogenfitration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorption physical nitrogen production | ||||

高品质分子筛

Highqualitymolecular sieve

好的分子筛不但可以快速分离气体,且使用时间长久,分子筛的恢复性能往往决定制氮的效率,因此从制氮细节上去筛选合格优质的碳分子作为分离核心至关重要。

Goodmolecularsievescannotonlyquicklyseparategases,butalsohavealongservicelife.The recoveryperformanceofmolecularsievesoftendeterminestheefficiencyofnitrogenproduction.Therefore,itiscrucialtoscreenqualifiedandhigh-qualitycarbonmoleculesfromthe detailsofnitrogenproductionastheseparationcore.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 15Nm3/h | 99.9% | 1150x900x1750 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 10Nm²/h | 99.99% | ||||

| 7Nm²/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detectormolecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device, high-quality pneumatic components. | ||||

| 工作原理 Workingprinciple | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

专业生产精工制造

Professionalproductionandprecisionmanufacturing

制氮机标配:吸附塔A、吸附塔B、活性炭除油器、氮气工艺罐,四位一体,结构紧凑,运输、安装、操作维护更方便。

Standardconfigurationofnitrogengenerator:adsorptiontowerA,adsorptiontowerB,acti vatedcarbondereasernitrogenprocesstank,fourinone,compactstructuremoreconvenienttransportation,installation,operationandmaintenance.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 20Nm3/h | 99.9% | 1250x1000x1820 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 15Nm3/h | 99.99% | ||||

| 8Nm3/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS)oil-waterseparation device,PLCcontrolsystem Nitrogenfiltration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

双塔交替连续制氮

Twin toweralternatingcontinuous nitrogenproduction

两个吸附塔交替进行吸附和再生,从而产生流量和纯度稳定的氮气。两支吸附塔的切换由程控系统和阀门组配和完成。

Twoadsorptiontowersalternatebetweenadsorptionandregeneration,producingnitrogengas withstableflowrateandpurity.Theswitchingbetweenthetwoadsorptiontowersiscompleted byacombinationofaprogrammablecontrolsystemandvalves.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dewpoint |

| 30Nm3/h | 99.9% | 1250x1250x2050 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 20Nm3/h | 99.99% | ||||

| 10Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-water separation device,PLC control system Nitrogen filtration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorption physicalnitrogen production | ||||

先进的制造工艺

Advancedmanufacturingtechnology

制氮机采用管道式气动阀、压紧气缸、吸附塔结构、变压吸附气体分离装置和控制方法、吸附塔结构、降噪措施。

Thenitrogengeneratoradoptspipelinepneumaticvalve,compressioncylinder,adsorption towerstructurepressureswingadsorptiongasseparationdeviceandcontrolmethod,adsorp tiontowerstructure,andnoisereductionmeasures.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 60Nm3/h | 99.9% | 1550x1250x2250 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 35Nm²/h | 99.99% | ||||

| 20Nm²/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieveCMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

杰出的可靠性

Outstandingreliability

坚固耐用的设计。持续运行(一天24小时,每周7天)。不会因为中断供气而停止

DurableandsturdyesinContinuousoperation24hoursaday7dasweek)Willnotst runningduetointerruptedgassupply

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 30Nm3/h | 99.9% | 1400x1150x2150 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 20Nm²/h | 99.99% | ||||

| 10Nm²/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-water separation device,PLC control system Nitrogenfiltration device,high-qualitypneumaticcomponents | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysicalnitrogenproduction | ||||

终极节能

UltimateEnergyEficiency

在不需要氮气时保持待机模式。周期时间调制算法 \leftrightharpoons 在氮气需求小时延长周期时间=在氮气需求小时减少空气消耗。

Maintain standbymodewhen nitrogenisnotneeded.Cycletimemodulation algorithm=Extend cycletimewhennitrogendemandislow=Reduceairconsumptionwhennitrogendemandis low.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 50Nm²/h | 99.9% | 1450x1150x2300 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 30Nm²/h | 99.99% | ||||

| 18Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system | ||||

| 工作原理 Working principle | Nitrogen filtration device,high-quality pneumatic components. PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

操作简单使用方便

Easytooperateandconvenienttouse

设备操作简单全自动运行,无需特备培训,全过程可实现无人值守。

Theequipmentiasytperatendrunautmaticallywithouttheeedfrsecialraning Theentireprocesscanbeunmanned.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogenpressure | 露点 The dewpoint |

| 70Nm²/h | 99.9% | 1850x1500x2300 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 45Nm²/h | 99.99% | ||||

| 30Nm²/h | 99.999% | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 | |||

| 设备配置 Equipment configuration | 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLC control system Nitrogen filtration device,high-quality pneumatic components. | ||||

| 工作原理 Workingprinciple | PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogenproduction | ||||

生产氮气高效快捷

Eficientandfastproductionofnitrogengas

先进的技术,独特的气流分布器,使气流分布更均匀,高效地利用碳分子筛15分钟左右即可提供合格的氮气

Advancedtechnologyandunique airflowdistributormaketheairflowdistributionmore uniformeffcientlyutiliingcarbonmolecularsievestoprovidequalifiednitrogengasinabout 15minutes

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 40Nm3/h | 99.9% | 1500x1250x2080 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃-20℃ |

| 25Nm3/h | 99.99% | ||||

| 15Nm²/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device,high-qualitypneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

静音低噪运行稳定

针对PSA设备的空气动力性及噪音频谱分析,采用阻抗复合型消音器,同时选择优质的阻性吸声材料和完善的抗性结构,有效消除高、中、低频噪音。

FortheaerodynamicandnoisespectrumanalysisofPsAequipment,animpedancecomposite mufflerisadopted,andhigh-qualityresistive sound-absorbingmaterialsandperfectresistance structuresareselectedtoeffectivelyeliminatehigh,medium,andlow-frequencynoise.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dewpoint |

| 60Nm3/h | 99.9% | 1500x1400x2400 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 40Nm²/h | 99.99% | ||||

| 25Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecularsieve(CMS),oil-waterseparationdevice,PLCcontrol system | ||||

| 工作原理 Working principle | Nitrogen filtration device, high-quality pneumatic components. PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

质量可靠使用寿命长

Reliablequalityandlngsevicelife

消耗低,同时消除了跑、冒、滴、漏的现象,达到环保运行的要求。

Lowconsumptionwhileelminatingthephenomenaofrunning,mitting,dripping,andleaking achievingtherequirementsofenvironmentallyfriendlyoperation.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 100Nm3/h | 99.9% | 2000x1700x2600 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 65Nm3/h | 99.99% | ||||

| 40Nm/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system | ||||

| 工作原理 Working principle | Nitrogen filtration device,high-quality pneumaticcomponents. PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogenproduction | ||||

流量与压力稳定控制

设备能够根据实际应用场景,精准调整氮气的输出流量和压力,确保在各种应用中都能稳定供应。

Theequipmentcanaccuratelyadjusttheoutputflowrateandpressureofnitrogenaccordingto actualapplicationscenariosensuringstablesupplyinvariousapplicatons.

| 氮气流量 Nitrogenflow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dewpoint |

| 50Nm3/h | 99.9% | 1500X1450×2250 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 30Nm3/h | 99.99% | ||||

| 18Nm3/h | 99.999% | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 | |||

| 设备配置 Equipment configuration | 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve(CMS).oil-waterseparation device,PLCcontrolsystem Nitrogen filtration device, high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

智能化控制与管理

IntelligentControlandManagement

制氮机配备先进的控制系统,包括PLC和触摸屏界面,实现自动化运行、故障预警及远程监控。这不仅简化了人工操作,还降低了出错率。

ThenitrogengeneratorisequippedwithanadvancedcontrolsystemincludingPLCandtouch screeninteface,toachieveautmatedoprationfaultwarning,ndremotemonitoringh notonlysimplifiesmanualoperations,butalsoreduceserrorrates.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 70Nm3/h | 99.9% | 1600x1250x2350 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 50Nm3/h | 99.99% | ||||

| 30Nm/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-water separation device,PLC control system Nitrogenfiltration device,high-qualitypneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorption physical nitrogen production | ||||

Thedesignemphasizesenergyefficiencybyadoptingenergy-savingaircompressorsoptimizing adsorptioncycles,andothermeasurestoreduceenergyconsumption,improveoperationaleffciency,andsavecostsfortheenterprise.

设计注重能效,通过采用节能型空压机、优化吸附周期等措施,降低能耗,提高运行效率,为企业节省成本。

高效能与低能耗

| 氮气流量 Nitrogenflow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 130Nm3/h | 99.9% | 2000x1600x2500 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 85Nm3/h | 99.99% | ||||

| 50Nm3/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecularsieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogenfiltration device,high-qualitypneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

Highefficiencyandlowenergyconsumption

维护简易便捷

Easyand convenientmaintenance

专业的制氮机设计充分考虑了维护的便利性,检修和更换部件更加简单,同时提供定期维护提醒功能,确保设备长时间稳定运行。

Theprofessionaldesignofthenitrogengeneratorfullyconsiderstheconvenienceof maintenance,makingiteasiertorepairandreplaceparts.Atthesametime,itprovidesregularmaintenancereminderstoensurethestableoperationoftheequipmentforalongtime.

| 氮气流量 Nitrogenflow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 90Nm3/h | 99.9% | 1800x1530x2450 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 60Nm²/h | 99.99% | ||||

| 35Nm²/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecularsieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogenfiltration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

纯度灵活调节

Flexiblepurityadjustment

为了满足不同行业的需求,制氮机能够灵活调整氮气的纯度,纯度范围通常介于95%至99.999%之间。这对于需要高纯度氮气的行业,如半导体制造业,尤为关键,以确保产品不受杂质污染。

Inordertomeettheneedsofdifferentindustriesnitrogengeneratorscanflexibly adjustthepurityof nitrogengas,withapurityrangeusuallybetween95%and 99.999%Thisisparticularlycrucialforindustriesthatrequirehigh-puritynitrogen,such assemiconductormanufacturing,toensurethatproductsarenotcontaminated by impurities.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 70Nm3/h | 99.9% | 1800x1500x2200 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 40Nm²/h | 99.99% | ||||

| 25Nm²/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

适应性强

Strongadaptability

高纯制氮机以其高纯度氮气输出、稳定可靠的性能、高效节能、操作简便和适应性强等特性,成为现代工业生产和科学研究中不可或缺的重要设备。

Thehigh-puritynitrogengeneratorhasbecomeanindispensableequipmentin modernindustrialproduction andscientificresearchduetoitshighpuritynitrogen outputstbleandelablefrmancehficenyandenrsavinas ation,andstrongadaptability.

| 氮气流量 Nitrogenflow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point | |

| 80Nm3/h | 99.9% | 1800x1500x2400 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ | |

| 50Nm²/h | 99.99% | |||||

| 30Nm3/h | 99.999% | |||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system, Nitrogen fitration device, high-quality pneumatic components. | |||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogenproduction | |||||

制氮机纯度不稳的原因

Improvethenitrogenpurityofthenitrogengenerator

1.制氮机的吸附压力不稳定如过高,超过了0.8Mpa或者是吸附压力过低,低于0.6Mpa;2.气源含水油量过多;3.出气部分接口漏气;4.进气量过大使压力上升过快;5.制氮机的分子筛中毒。

1.Theadsorptionpressureof thenitrogengeneratorisunstable,such asbeingtoohigh, exceeding 0.8\mathsf{M}\mathsf{p a} ortoolow,below0.6Mpa;2.Excessivewaterandoilcontentinthe gas source;3.Airleakageat theoutletinterface;4.lf theintakevolumeistoolarge,the pressure will risetoo quickly;5.Molecular sieve poisoning of nitrogen generator.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 130Nm3/h | 99.9% | 2000x1500x2300 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 80Nm3/h | 99.99% | ||||

| 45Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecularsleve(CMS),oll-waterseparation device,PLCcontrol system Nitrogenfiltration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogen production | ||||

制氮机的五大组成部分

压缩空气净化系统、空气储罐系统、氧氮分离系统、氮气缓冲系统、电气控制系统

Compressedairurificatonsystemirstoragetanksystemoxyen nitrogenseparationsystemnitrogenbuffersystemlectricalcontrol system

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 100Nm3/h | 99.9% | 2900x1200x2400 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃-20℃ |

| 60Nm²/h | 99.99% | ||||

| 40Nm/h | 99.999% | ||||

| 设备配置 Equipment configuratice | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve (CMS), oil-water separation device,PLC control system, Nitrogen filtration device, high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机的安全使用事项

Safetyprecautionsforusingnitrogengenerator

1、接电源前,请仔细检查整个工业制氮机。2、启动时,请将排气阀设为空压状态,以免超过空压。3、定期检查安全装置的可靠性(安全阀等)。4、维护工作须在停止、停电时进行。

1.Beforeconnectingthepower supplypleasecarefullyinspecttheentireindustrial nitrogengenerator.2.Whenstarting,pleasesettheexhaustvalvetotheairpressure statetoavoidexceedingtheairpressure.3.Regularlycheckthereliabilityof safety devices(such as safety valves).4.Maintenance workmust be carriedoutduring shutdownsorpoweroutages.

| 氮气流量 Nitrogenflow rate | 氮气纯度 Nitrogenpurity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 150Nm²/h | 99.9% | 2000x1600x2600 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 100Nm²/h | 99.99% | ||||

| 60Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecular sieve (CMS),oil-waterseparation device,PLCcontrol system Nitrogenfiltration device,high-qualitypneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorption physical nitrogen production | ||||

制氧机的安全警示

Safety WarningforOxygenGenerator

由于整个制氧系统中气体均是带压的,需防止压力气体的加渣冲击。在空压机、干燥机、制氧主机等设备的排气口,请勿站人。整个系统中的连接管路必须牢固、可靠、密封,必须经设备销售商确认,以免因漏气或管路破裂而造成人员伤亡或财物损坏。

Duetothefactthatthegasintheentireoxygenproductionsystemispressurized,itisnecessaryto prevent the slagimpact of pressurizedgas.Donot stand atthe exhaust ports of air compressors, dryers,oxygengenerators,andotherequipment.Theconnectingpipelinesintheentiresystem mustbefirm,reliable,and sealed,andmustbe confirmed bythe equipment sellerto avoid personal injury or property damagecaused by air leakage or pipelinerupture.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogenpressure | 露点 The dew point |

| 120Nm²/h | 99.9% | 2000x1600x2500 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 75Nm3/h | 99.99% | ||||

| 45Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve(CMS),oil-water separation device,PLC control system Nitrogen filtration device,high-quality pneumatic components | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorption physical nitrogenproduction | ||||

制氮机的基本参数

Basicparametersofnitrogengenerator

氮气有四个基本参数需要注意,即流量、纯度、露点和压力。参数值因用途不同而异,供需双方为取得共识。

Therearefourbasicparametersofnitrogenthatneedtobenoted,namelyflowrate, purity,dewpoint,andpressureTheparametervaluesvarydpendingonthepurpose, andboththesupply anddemandsidesneed toreachaconsensus.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogenpurity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Alrpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 150Nm3/h | 99.9% | 2150x1700x2500 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 100Nm3/h | 99.99% | ||||

| 60Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sleve(CMS),oil-water separation device,PLCcontrol system Nitrogen fitration device,high-quality pneumatic components. | ||||

| 工作原理 Workingprinciple | PSA变压吸附物理制氮 PSApressure swing adsorption physical nitrogen production | ||||

制氮机均压的好处

hebeeftfsureqnroge均压的好处有两个,一是减少气体对分子筛的冲击,二是提高压缩空气利用率。不等势均压流程更合理、更科学、更成熟,其直接效果是氮气回收率提高,产气量上升,其间接效果是可降低 30% 的能耗

Therearetwobeneftstopressureequaliztion:oneistoreducetheimpactof gasonmolecular sieves, and the other is to mprove the utilizationrate of compressed air.The unequal potentialpressureequalizationprocessismorereasonablescientific,andmaturelts direct effectistoincrease thenitrogenrecoveryrateandgasproduction,and itsindirecteffectisto reduceenergyconsumptionby30%

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 200Nm²/h | 99.9% | 3100x1500x2800 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃-20℃ |

| 120Nm²/h | 99.99% | ||||

| 75Nm/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve (CMS),oil-water separation device,PLC control system Nitrogen filtration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机应注意哪点

1.系统设计的合理性;2.碳分子筛装填技术;3.控制阀门的使用寿命;

4.研究开发,制造经验、用户使用情况。

1.Rationalityof systemdesign;2Carbonmolecularsieveloadingtechnology;3Control theserviclfvalves;esearchanddveopmentmanufacturingexperiencn userusage.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 300Nm²/h | 99.9% | 2600x1600x3000 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 180Nm²/h | 99.99% | ||||

| 120Nm²/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecular sieveCMS),oil-waterseparationdevice,PLCcontrolsystem Nitrogen filtration device,high-quality pneumaticcomponents | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机使用注意事项

Precautions forusingnitrogengenerator

1、制氮气需加氢除氧,在制氮机室内严禁存在明火。2、生产后的废气要按要求处理排出室外,且周围5m之内不得有明火及堆放易燃物质的存在。3、氮气是一种室息性气体,严禁在制氮机处睡觉休息。

1.Nitrogenproductionrequireshydrogenationanddeoxygenation,andopenflamesarestrictly prohibitedinthenitrogenproductionroom.2.Theexhaustgasafterproductionshouldbetreated anddischargedoutdoorsasrequired,andthereshouldbenoopenflamesorflammablematerials piledupwithin5metersaround it.3.itrogenisasuffocatinggasandsleepingorrestingatthe nitrogengeneratorisstrictlyprohibited.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dewpoint |

| 750Nm3/h | 99.9% | 3200x1700x3000 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃-20℃ |

| 500Nm²/h | 99.99% | ||||

| 300Nm/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 NitrogendetectormolecularsieveCMS),il-waterseparationdevicePLCcontrolsystm, Nitrogenfitration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogenproduction | ||||

制氮机必须具备的性能

Theestialfomanfanitrgengeneratr

1、控制阀门的材质性能好,绝对不能够有漏气情况;2、能够保证制氮机控制阀门足够长的使用寿命,能够进行频繁的开关操作;3、在接受控制信号0.02s内,制氮机控制阀门就能够完成信号所指的开/关操作。

1.Thematerialperformance of thecontrolvalveisgood,and theremustbenoair leakage;2.Canensure thatthe control valve of thenitrogengeneratorhasasuffcientlylongservice lifeandcanperformfrequentswitchingoperations;3.Within0.02 secondsofreceivingthecontrolsignal,thecontrolvalveof thenitrogengeneratorcan completetheon/offoperationindicatedby thesignal.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 600Nm3/h | 99.9% | 4000x1700x3200 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 350Nm²/h | 99.99% | ||||

| 230Nm/h | 99.999% | ||||

| 设备配置 Eqipmert configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve (CMS),oil-water separation device,PLC control system. Nitrogenfiltration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

定制化制氮机

Customizednitrogengenerator

定制化制氮机的设计理念源于对客户需求的深入了解和精准把握。无论是小型实验室对微量高纯度氮气的需求,还是大型工业企业对大规模氮气供应的要求,我们都能根据客户的具体情况量身走制最适合的制氮解决方案。

Thedesignconcept of customized nitrogengeneratororiginates fromadeepunderstanding and precisegrasp ofcustomerneeds.Whetherit isthedemand fortracehigh-puritynitrogen insmallaboratoriesortherequirementforlarge-scalenitrogensupply in largeindustrial enterprises,wecantailorthemostsuitablenitrogenproductionsolutionaccordingtothe specificsituationofourcustomers.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 1200Nm2/h | 99.9% | 3100x1500x2800 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃-20℃ |

| 750Nm2/h | 99.99% | ||||

| 450Nm2/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve (CMS),il-water separation device,PLCcontrol system Nitrogenfiltration device,high-quality pneumatic components | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

带压力容器证制氮机

随着科学技术的进步和经济建设的发展,氮气的应用范围日益广泛,并已深入到许多工业企业和日常生活领域。而随着变压吸附制氮机技术的成熟,制氮机现场制氮比其他供氮方式更经济,更便捷。

Withtheadvancementof scienceandtechnologyand thedevelopmentofeconomicconstruction,theapplicationscopeofnitrogenisbecomingincreasinglywidespreadandhaspenetrated intomanyindustrialenterprisesanddaily lifefields.Withthematurityofpressureswing adsorptionnitrogengeneratortechnology,on-sitenitrogenproductionbynitrogengeneratorsis moreeconomicalandconvenientthanothernitrogensupplymethods.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point | |

| 15Nm²/h | 99.9% | 1150X900×1700 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ | |

| 10Nm²/h | 99.99% | |||||

| 7Nm²/h | 99.999% | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 | ||||

| 设备配置 Equipment configuration | 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve (CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device,high-quality pneumaticcomponents. | |||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogenproduction | |||||

制氮机在煤炭行业的用途

在煤矿中,采空区氧化区域发生火灾时,最大的灾难是内部混合气体的爆炸。充入氮气可以将混合气体中的氧气含量控制在 12% 以下,这样既可以抑制爆炸概率,也可以防止煤自燃,让工作环境更加安全。

Incoalmines,thebiggestdisasterwhenafireoccursintheoxidizedareaofthegoaf isthe explosionof theinternalmixedgas.Fillingnitrogencancontroltheoxygencontent inthemixed gasbelow 12% whichcansuppresstheprobabilityofexplosionandpreventcoalspontaneous combustion,makingtheworkingenvironmentsafer.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 20Nm3/h | 99.9% | 1150x900x1850 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 15Nm²/h | 99.99% | ||||

| 8Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecularsieve(CMS),oil-waterseparationdevice,PLCcontrol system Nitrogen filtration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机橡胶、树脂生产行业应用

Therubbernitrogenvulcanizationprocessinvolvesaddingnitrogengasasaprotectivegas duringtherubbervulcanizationprocess.

橡胶氮气硫化工艺,即在橡胶硫化的过程中,加入氮气充当保护气。

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogenpressure | 露点 The dew point |

| 20Nm3/h | 99.9% | 1250x1000x1900 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃-20℃ |

| 15Nm/h | 99.99% | ||||

| 8Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecular sieveCMS),oil-waterseparationdevice,PLCcontrol system Nitrogen filtration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysicalnitrogenproduction | ||||

制氮机石油和天然气开采

Nitrogengeneratorforoilandgasextraction

氮气是用于对来自大井/天然气藏区的油气进行再加压的标准气体。利用氮的自身特性来维持油层压力,混合相以及不混溶的驱油和重力排水技术可以大大提高采油率,这对稳定石油生产和提高石油产量也具有重要意义。

Nitrogen is a standardgas used torepressurizeoil andgasfrom largewells/naturalgasreservoirs.Utilizingtheinherentcharacteristicsofnitrogentomaintainreservoirpressure,mixed phaseandimmiscibleoildisplacementandgravitydrainagetechnologiescangreatlyimproveoil recoveryrates,whichisalsoof greatsignificanceforstabilizingoilproductionandincreasingoil output.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 30Nm3/h | 99.9% | 1500x1200x1950 | 0.65-0.8Mpa | 0.1-0.7Mpa | |

| 20Nm3/h | 99.99% | -40℃~-20℃ | |||

| 10Nm/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS),oil-water separation device,PLCcontrol system Nitrogenfiltration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机在制药行业应用

Applicationofnitrogengeneratorinpharmaceuticalindustry

在制药行业,氮气填充工艺能有效提高药品质量,无论是输液剂、水针、粉针、冻干机还是口服液生产等。

Inthepharmaceutical industry,nitrogenfllingtechnologycaneffectivelyimprovethequalityof drugshetheritisthproductionofinfusionolutonswaterinjectionpowderinjections freeze-dryingmachines,ororalliquids.

| 氮气流量 Nitrogenflow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogenpressure | 露点 The dewpoint |

| 50Nm3/h | 99.9% | 1500×1430×2020 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 30Nm3/h | 99.99% | ||||

| 18Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector, molecular sieve (CMS),oil-water separation device,PLC control system, | ||||

| 工作原理 Working principle | Nitrogen filtration device,high-quality pneumatic components. PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogenproduction | ||||

制氮机在塑料化工的用途

将氮气引入到塑料零件的成型和冷却过程中,使用氮气减少由塑料零件上的压力引起的变形,从而获得稳定,准确的塑料零件尺寸。使用氮气注塑,可以提高注塑产品的质量和设计的灵活性。

Introducingnitrogenintothemoldingandcoolingprocessofplasticparts,usingnitrogento reducedeformationcausedbypressureontheplasticparts,therebyobtainingstableand accurateplasticpartdimensions.Usingnitrogeninjectionmoldingcanimprovethequalityand designflexibilityof injectionmoldedproducts.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 60Nm3/h | 99.9% | 1500x1220x2250 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 40Nm3/h | 99.99% | ||||

| 25Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机在冶金及热处理应用

Applicationofnitrogengeneratorinmetallurgyandheatreatment

连铸、连轧、钢材退火的保护气;转炉顶底符合吹氮炼钢,转炉炼钢的密封,高炉炉顶的密封,高炉炼铁煤粉喷吹用气等。

Protectivegasforcontinuouscasting,rolling,andsteelannealing;Thetopandbottomofthe converteraresuitablefornitrogenblowingsteelmaking,sealingofconvertersteelmaking, sealingofblastfurnacetop,andgasinjectionforblastfurnaceironmakingcoalpowder.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dewpoint |

| 150Nm3/h | 99.9% | 2000x1520x2350 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 100Nm²/h | 99.99% | ||||

| 60Nm3/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecular sieve(CMS)oil-waterseparation device,PLCcontrol system Nitrogen filtration device, high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机在新型材料应用

Applicationofnitrogengeneratorinnewmaterials

新型材料及复合材料的热处理气氛保护。

Thermaltreatmentatmosphereprotectionfornewmaterialsandcompositematerials.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogenpressure | 露点 The dew point |

| 200Nm²/h | 99.9% | 2200x2200x2500 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 120Nm/h | 99.99% | ||||

| 70Nm²/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecularsieve(CMS),il-water separation device,PLCcontrol systm Nitrogen filtration device, high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机在航空航天应用

氮气用于设备的检漏和压力检测,并在火箭和航天器的燃料储存及输送中作为情性气体使用。

Nitrogenisusedforleakdetectionandpressuretestingofequipmentandasaninertgasnful storageandtransportationofrocketsandspacecraft.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 15Nm²/h | 99.9% | 1400X1000×1670 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 10Nm3/h | 99.99% | ||||

| 7Nm²/h | 99.999% | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve (CMS),oil-water separation device,PLCcontrol system Nitrogenfiltration device,high-quality pneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorption physical nitrogen production | ||||

制氮机在玻璃制造的用途

Theuseofnitrogengeneratoringlassmanufacturing

在玻璃熔炼过程中,氮气作为保护气体防止玻璃氧化;在浮法玻璃生产中形成保护层,改善产品质量。

Duringthglasmltingprcessnitrogenservessprotctivegastpreventassoxidatn Formingaprotectivelayerinfloatglassproductiontoimproveproductquality.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipment size(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 6Nm3/h | 99.9% | 1000x800x1750 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 5Nm²/h | 99.99% | ||||

| 3Nm/h | 99.999% | ||||

| 设备配置 Equipmentconfiguration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve(CMS)oil-waterseparation device,PLCcontrol system Nitrogen filtration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

制氮机在电子行业应用

Applicationfnitrogengeneratorinthlectrnicindstry

制氮机提供的高纯度氮气用于电路板焊接、芯片封装和元器件储存,防止电子元件氧化,保护其品质和稳定性,尤其在无铅焊接工艺中非常重要

Thehigh-puritynitrogengasprovided bythenitrogengeneratorisusedforcircuitboardsoldering,chippackaging,andcomponent storagetopreventoxidationofelectroniccomponents, protecttheirqualityandstability,andisparticularlyimportantinlead-freesolderingprocesses

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogenpurity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point | |

| 30Nm²/h | 99.9% | 1350x1150x1850 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ | |

| 20Nm3/h | 99.99% | |||||

| 10Nm²/h | 99.999% | |||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogendetector,molecularsieve(CMS)oilwaterseparation device,PLCcontrol system Nitrogen filtration device, high-quality pneumatic components. | |||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | |||||

制氮机在食品行业应用

Applicationofnitrogengeneratorinnewmaterials

在食品行业中,制氮机主要用于食品的保鲜和包装。氮气是一种情性气体,可以有效防止食品中的氧化反应,从而延长食品的保质期。

Inthefoodindustrynitrogengeneratorsaremainlyusedforfoodpreservationandpackaging.Nitrogenisaninertgasthatcaneffectivelypreventoxidationreactionsinfood,thereby extendingtheshelf lifeoffood.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 30Nm3/h | 99.9% | 1350x1150x1830 | 0.65-0.8Mpa | 0.1-0.7Mpa | -40℃~-20℃ |

| 20Nm3/h | 99.99% | ||||

| 10Nm²/h | %66666 | ||||

| 设备配置 Equipment configuration | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 氮气过滤装置、优质气动元件。 Nitrogen detector,molecularsieve(CMS),oil-water separation device,PLCcontrol system, Nitrogen filtration device, high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

高压制氮机

Highpressure nitrogengenerator

设备直接从空气中提取高纯度氮气,并对氮气进行增压,无需购买补充气源,成本低廉,性价格高。

Theequipmentdirectlyextractshigh-puritynitrogenfromtheairandpressurizesthenitrogen withouttheneedtopurchasesupplementarygassourceswithlowcostandhighcost-effectiveness.

| 氮气流量 Nitrogenflowrate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Air pressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 15Nm²/h | 99.95% | 1400×700×1850 | ≤1.6Mpa | ≤1.6Mpa | -40℃~-20℃ |

| 10Nm3/h | 99.99% | ||||

| 7Nm²/h | 99.999% | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 | |||

| 设备配置 Equipment configuration | 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve (CMS), oil-water separation device,PLC control system Nitrogenfitration device,high-qualitypneumaticcomponents. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSApressure swing adsorptionphysical nitrogenproduction | ||||

高压制氮机

Highpressurenitrogengenerator

缸体可选用碳钢或不锈钢材料,采用进口密封件,活塞干式运行,无任何润滑油,性能稳定,可靠性高。

Thecylinderbodycanbemadeofcarbonsteelorstainlesssteelmaterial,withimportedsealing components.Thepistonoperatesdrywithoutanylubricatingoilwithstableperformanceand highreliability.

| 氮气流量 Nitrogen flow rate | 氮气纯度 Nitrogen purity | 设备尺寸(mm) Equipmentsize(mm) | 空气压力 Airpressure | 氮气压力 Nitrogen pressure | 露点 The dew point |

| 30Nm3/h | 99.9% | 1450x850x1800 | ≤1.6Mpa | ≤1.6Mpa | -40℃~-20℃ |

| 20Nm²/h | 99.99% | ||||

| 10Nm²/h | 99.999% | 氮气检测仪、分子筛(CMS)油水分离装置、PLC控制系统、 | |||

| 设备配置 Equipment configuration | 氮气过滤装置、优质气动元件 Nitrogen detector,molecular sieve(CMS),oil-waterseparation device,PLCcontrol system Nitrogen filtration device,high-quality pneumatic components. | ||||

| 工作原理 Working principle | PSA变压吸附物理制氮 PSA pressure swing adsorption physical nitrogen production | ||||

一体化撬装制氮系统

Integratedprymountednitrogenproductionsystem

我公司独特的撬式制氮机,可消除氮气的运输和停机成本。它配有空气压缩机、空气处理设备、制氮机及必要的容器和控制器。这些部件都安装在一个紧凑的预调试撬块上。这些系统包括可确保无缝运行的制氮装置。

Ourcompany'suniqueprytpenitrogengeneratrcaneliminatethetransportationanddowntimecostsofnitrogengas.tisequppedwithanaircompressor airtreatmentqupmentntrogengeneratrandcessarycontanersandcontrollersheecmonentarealinstalledncmpactprcmmissonng pryblock.Thesesystemsincludenitrogengenerationdevicesthatensureseamlessoperation.

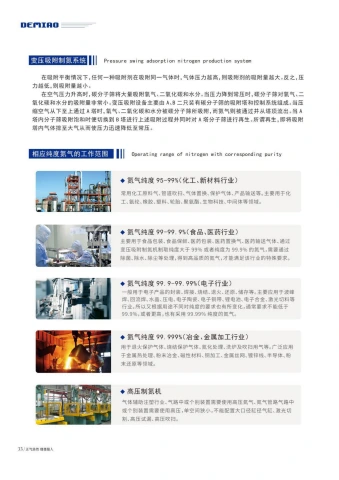

变压吸附制氮系统

在吸附平衡情况下,任何一种吸附剂在吸附同一气体时,气体压力越高,则吸附剂的吸附量越大。反之,压力越低,则吸附量越小。

在空气压力升高时,碳分子筛将大量吸附氧气、二氧化碳和水分。当压力降到常压时,碳分子筛对氧气、二氧化碳和水分的吸附量非常小。变压吸附设备主要由A、B二只装有碳分子筛的吸附塔和控制系统组成。当压缩空气从下至上通过A塔时,氧气、二氧化碳和水分被碳分子筛所吸附,而氮气则被通过并从塔顶流出。当A塔内分子筛吸附饱和时便切换到B塔进行上述吸附过程并同时对A塔分子筛进行再生。所谓再生,即将吸附塔内气体排至大气从而使压力迅速降低至常压。

相应纯度氮气的工作范围

Operatingrangeofnitrogen withcorrespondingpurity

氮气纯度 95{-}99% (化工、新材料行业)

常用化工原料气、管道吹扫、气体置换、保护气体、产品输送等。主要用于化工、氨纶、橡胶、塑料、轮胎、聚氨酯、生物科技、中间体等领域。

氮气纯度99-99.9%(食品、医药行业)

主要用于食品包装、食品保鲜、医药包装、医药置换气、医药输送气体、通过变压吸附制氮机制取纯度大于99%或者纯度为 99.9% 的氮气,需要通过除菌、除水、除尘等处理,得到高品质的氮气,才能满足该行业的特殊要求。

氮气纯度99.9-99.99%(电子行业)

一般用于电子产品的封装、焊接、烧结、退火、还原、储存等。主要应用于波峰焊、回流焊、水晶、压电、电子陶瓷、电子铜带、锂电池、电子合金、激光切料等行业。所以又根据用途不同对纯度的要求也有所变化,通常要求不能低于99.9% 或者更高,也有采用99.99%纯度的氮气。

氮气纯度99. 999% (冶金、金属加工行业)

用于退火保护气体、烧结保护气体、氮化处理、洗炉及吹扫用气等。广泛应用于金属热处理、粉末冶金、磁性材料、铜加工、金属丝网、镀锌线、半导体、粉末还原等领域。

高压制氮机

气体辅助注塑行业、气路中或个别装置需要使用高压氮气、氮气管路气路中或个别装置需要使用高压,单空间狭小,不能配置大口径缸径气缸、激光切割、高压试漏、高压吹扫。

部分成功案例

可定制各尺寸、产量制氮机

CustomizableNitrogenMachinesofVariousSizesandYields

石家庄德淼科技有限公司ShijiazhuangDemiao Technology Co.,Ltd

地址:河北省石家庄市赵县工业园区电话:159-3105-2655网址:http://www.sjzdemiao.com/

该页无缩略图

该页无缩略图